High Quality Insulating Fire Brick - Insulation Bricks Refractory 23 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Insulation Brick:

CMAX insulating firebricks are classified under temperature between 1100℃ to 1700℃, manufactured from high purity alumina clay..

2.Main features of Insulation Brick:

◆Light weight and low thermal conductivity ◆Low heat storage

◆Low iron and impurities ◆High thermal shock resistance

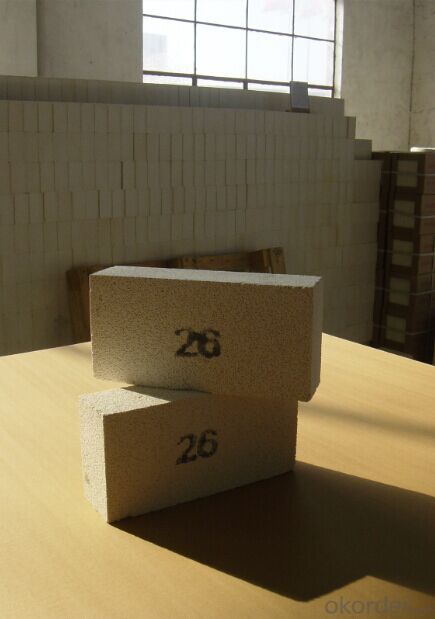

3. Insulation Brick Images:

4. Insulation Brick Technical Parameters

Our Insulation Brick contains 20, 23, 25,26, 28, 30, 32. Classification temperature is from 1100℃ to 1760℃. Density is from 0.52g/cm3 to 1.25g/cm3. As we all know, the company type is 23 and 26.

1) For the 23, its density is 0.52g/cm3, but some customer may require 0.8g/cm3, we can also meet your special require. Content of Al2O3 is about 45%.

2) For the 26, its density is 0.8g/cm3, but if you have other special requirement on that, pls also tell us. Content of Al2O3 is about 55%.

Application: CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our Insulation Brick?

A world class manufacturer & supplier of InsulationBrick is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can insulating fire bricks be used in the construction of drying ovens?

- Yes, insulating fire bricks can be used in the construction of drying ovens. These bricks are designed to withstand high temperatures and have excellent thermal insulation properties, making them ideal for creating a heat-efficient environment in drying ovens. They can help in maintaining a consistent temperature and preventing heat loss, thereby improving the drying process and energy efficiency of the oven.

- Q: Can insulating fire bricks be used in chemical processing plants?

- Indeed, chemical processing plants can utilize insulating fire bricks. These bricks are specifically engineered to endure elevated temperatures and offer exceptional thermal insulation. Consequently, they are suitable for a wide range of industrial applications, including chemical processing plants. They can be employed to line furnaces, kilns, reactors, and other apparatuses where high temperatures are involved. The exceptional thermal insulation properties of insulating fire bricks aid in reducing heat loss, enhancing energy efficiency, and maintaining a steady temperature within the processing equipment. Furthermore, these bricks exhibit resistance to chemical corrosion and can withstand the rigorous conditions typically encountered in chemical processing plants. Ultimately, insulating fire bricks serve as a dependable and efficient choice for insulating and safeguarding equipment in chemical processing plants.

- Q: Can insulating fire bricks be used in high-temperature kilns and furnaces?

- High-temperature kilns and furnaces can indeed utilize insulating fire bricks. These bricks are specifically designed to endure extreme heat and offer remarkable insulation properties. They consist of lightweight refractory materials, including clay and silica, which possess high melting points and low thermal conductivity. By effectively retaining heat, these bricks decrease energy loss and enhance the efficiency of the kiln or furnace. Moreover, insulating fire bricks exhibit excellent resistance to thermal shock, enabling them to withstand rapid temperature fluctuations without cracking or breaking. Consequently, they are well-suited for high-temperature applications that involve frequent heating and cooling cycles in kilns or furnaces. All in all, insulating fire bricks represent an ideal choice for insulating and safeguarding high-temperature kilns and furnaces.

- Q: Can insulating fire bricks be used in smelting furnaces?

- Yes, insulating fire bricks can be used in smelting furnaces. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They help in reducing heat loss and improving energy efficiency in the smelting process.

- Q: Do insulating fire bricks have a high heat storage capacity?

- Insulating fire bricks possess a remarkable capacity for storing heat. These bricks are engineered to possess minimal thermal conductivity, enabling them to preserve heat for extended durations. Consequently, they are extremely well-suited for scenarios that demand heat retention, such as within furnaces, kilns, and other settings with elevated temperatures. The impressive heat storage capacity of insulating fire bricks facilitates effective heat preservation and dispersion, ultimately enhancing energy efficiency and lessening heat dissipation.

- Q: Is the building built of cement hollow board safe?

- According to the use of building housing, before the use of cement hollow plate, it is necessary to predict the bearing capacity of housing, if more than the cement hollow plate bearing indicators, it is not available, it is unsafe;

- Q: Are insulating fire bricks resistant to thermal spalling?

- Yes, insulating fire bricks are resistant to thermal spalling. Thermal spalling refers to the phenomenon where a material cracks or breaks due to rapid temperature changes or thermal shock. Insulating fire bricks are specially designed to withstand high temperatures and thermal cycling without spalling. They have a low thermal conductivity, which means they can effectively insulate against heat transfer and minimize the stress caused by thermal expansion and contraction. Additionally, the composition and structure of insulating fire bricks are engineered to provide excellent resistance to thermal spalling, making them a reliable choice for applications that involve extreme heat conditions.

- Q: Can insulating fire bricks be used in the construction of lime production ovens?

- Indeed, the utilization of insulating fire bricks is feasible when constructing lime production ovens. These fire bricks are engineered with the explicit purpose of enduring elevated temperatures and offering optimal thermal insulation. The fabrication of lime necessitates materials capable of enduring the intense heat generated while converting limestone into lime. Insulating fire bricks possess not only exceptional heat resistance, but they also exhibit minimal thermal conductivity, thus reducing heat dissipation and enhancing energy efficiency throughout the lime production procedure. Moreover, these fire bricks are lightweight and effortlessly manageable, rendering them suitable for the construction of lime production ovens.

- Q: Are insulating fire bricks suitable for use in aluminum smelting furnaces?

- Insulating fire bricks are not typically suitable for use in aluminum smelting furnaces. Aluminum smelting requires high temperatures, often exceeding 1,000 degrees Celsius, and insulating fire bricks are designed to have low thermal conductivity, meaning they are better at retaining heat rather than withstanding extreme temperatures. For aluminum smelting, refractory fire bricks or refractory castables are more appropriate. These materials have high melting points and are capable of withstanding the intense heat produced during the smelting process without losing their structural integrity. They also have good thermal shock resistance, which is important as the furnace may experience rapid temperature changes during operation. Additionally, refractory materials used in aluminum smelting furnaces should have good resistance to corrosion and chemical attack from the molten aluminum and other materials used in the process. Insulating fire bricks may not have the necessary chemical resistance, which could lead to premature degradation and failure of the furnace lining. In summary, while insulating fire bricks may be suitable for other applications that require good thermal insulation, they are generally not recommended for use in aluminum smelting furnaces. Refractory fire bricks or refractory castables are better suited for this high-temperature and chemically aggressive environment.

- Q: Can insulating fire bricks be used in the construction of hot water boilers?

- Yes, insulating fire bricks can be used in the construction of hot water boilers. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for applications such as hot water boilers where heat retention is crucial.

Send your message to us

High Quality Insulating Fire Brick - Insulation Bricks Refractory 23 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords