Insulating Fire Brick - High-Quality Insulation Brick Refractory Heat Resistant Building Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

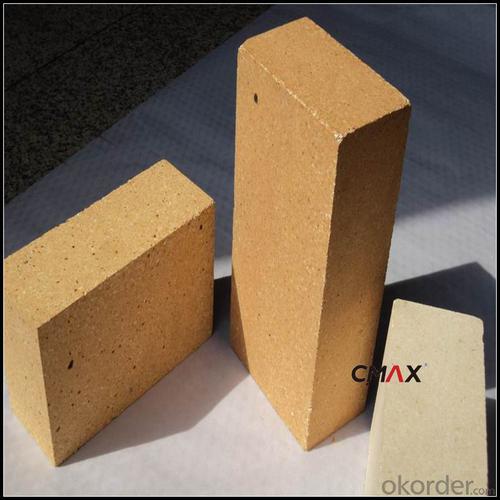

Insulating Brick

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Refractory brick is dense shaped refractory material. With high refractoriness and mechanical behavior under high temperature, refractory brick is the necessary material of high-temperature services, mainly used for industrial furnaces and kilns and thermal equipment.

Refractory brick for blast furnace is mainly used in stack, bosh, bellly and bottom of blast furnace.

Insulating Brick Features

1.Refractory brick manufacturer

2.ISO9001:2000 certificate

3.Timely delivery and best service

Insulating Brick Application

glass industries iron & steel industries

ceramics industries non-ferrous metals industries

electrolytic Aluminum industries power generation industries

Heat surface fireproof lining other fire-proof back lining

Insulating Brick Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Do insulating fire bricks require any special insulation blankets or jackets?

- Yes, insulating fire bricks do require special insulation blankets or jackets in order to enhance their insulating properties and protect them from heat loss and damage. These blankets or jackets help to create a barrier that prevents the transfer of heat, ensuring maximum insulation and energy efficiency.

- Q: Can insulating fire bricks be used for insulation in heat exchangers?

- Yes, insulating fire bricks can be used for insulation in heat exchangers. Insulating fire bricks are made from a lightweight refractory material that has excellent thermal insulation properties. They have low thermal conductivity, which means they can effectively reduce heat transfer from one side of the heat exchanger to the other. This helps to maintain the desired temperature within the heat exchanger and prevents heat loss to the surroundings. Additionally, insulating fire bricks are resistant to high temperatures and can withstand thermal shocks, making them suitable for the harsh conditions often found in heat exchangers. Overall, using insulating fire bricks for insulation in heat exchangers can improve energy efficiency, reduce heat loss, and enhance the overall performance of the system.

- Q: Are insulating fire bricks resistant to warping?

- Yes, insulating fire bricks are generally resistant to warping. Insulating fire bricks are designed to withstand high temperatures and thermal shocks, which helps prevent warping. These bricks are made from lightweight materials such as clay, silica, and alumina, combined with additives to enhance their insulating properties. These additives also contribute to the brick's ability to resist warping. Additionally, insulating fire bricks undergo a specific manufacturing process that helps ensure dimensional stability and minimize the risk of warping. However, it's important to note that extreme and prolonged exposure to high temperatures can still cause some degree of warping, but compared to other types of bricks, insulating fire bricks offer a higher level of resistance.

- Q: Do insulating fire bricks require special installation techniques?

- Yes, insulating fire bricks do require special installation techniques. These bricks are designed to withstand high temperatures and provide insulation, so proper installation is crucial to ensure their effectiveness. Special attention needs to be given to factors such as mortar selection, brick alignment, and proper curing to achieve optimal thermal performance.

- Q: Can insulating fire bricks be used for insulation in residential walls?

- Insulating fire bricks are not suitable for residential walls as insulation, as they do not meet the specific requirements of residential construction. While they are effective in industrial settings like furnaces and kilns, they have limitations in residential applications. Compared to traditional insulation materials like fiberglass or foam, insulating fire bricks have a higher thermal conductivity, which means they conduct heat more efficiently. As a result, residential walls with insulating fire bricks can experience significant heat loss and reduced energy efficiency. In addition, insulating fire bricks are larger and heavier than conventional insulation materials, making their installation in residential walls more difficult and costly. They also lack the flexibility and ease of use that other insulation materials offer. For residential purposes, it is recommended to use insulation materials specifically designed for residential walls, such as fiberglass batts, foam boards, or spray foam insulation. These materials are lightweight, easy to install, and provide excellent thermal insulation properties. They help maintain a comfortable indoor temperature and reduce energy consumption.

- Q: Can insulating fire bricks be used in the construction of incinerators?

- Yes, insulating fire bricks can be used in the construction of incinerators. Insulating fire bricks have excellent thermal insulation properties, which are crucial in maintaining high temperatures and improving energy efficiency within the incinerator. These bricks have a low thermal conductivity, allowing them to effectively retain heat and minimize heat loss. Additionally, insulating fire bricks are resistant to high temperatures and can withstand the intense heat generated by the incineration process. This makes them a suitable choice for lining the walls, floors, and roofs of incinerator chambers, helping to ensure the efficient and safe operation of the incinerator.

- Q: Do insulating fire bricks have a low thermal expansion rate?

- Yes, insulating fire bricks generally have a low thermal expansion rate. These bricks are designed to withstand high temperatures and thermal shocks, and one of their key properties is their ability to maintain their shape and dimensions under extreme heat conditions. Insulating fire bricks are made from materials that have a low coefficient of thermal expansion, meaning they expand and contract minimally when exposed to changes in temperature. This low thermal expansion rate ensures that the bricks remain stable and do not crack or break due to thermal stress. Additionally, the low thermal expansion rate of insulating fire bricks allows for better insulation performance, as it minimizes the gaps that can form between the bricks when they expand and contract, reducing heat loss and increasing energy efficiency.

- Q: Can insulating fire bricks be used in ladles and tundishes?

- Yes, insulating fire bricks can be used in ladles and tundishes. Insulating fire bricks are designed to withstand high temperatures, making them suitable for use in these refractory applications. They provide excellent thermal insulation, reducing heat loss and improving energy efficiency in ladles and tundishes.

- Q: Are insulating fire bricks suitable for insulation in walls?

- Yes, insulating fire bricks are suitable for insulation in walls. They are designed to have excellent thermal insulation properties, high heat resistance, and low thermal conductivity. These characteristics make them effective at reducing heat transfer and providing insulation in wall systems.

- Q: Are insulating fire bricks resistant to chlorine gas?

- Yes, insulating fire bricks are generally resistant to chlorine gas. Insulating fire bricks are made from refractory materials, which are designed to withstand high temperatures and resist chemical corrosion. Chlorine gas is a highly reactive substance and can cause corrosion or damage to many materials. However, insulating fire bricks have a high resistance to chemical attack, making them suitable for applications where they may come into contact with chlorine gas. It is important to note that the specific composition and quality of the insulating fire bricks can vary, so it is always recommended to consult the manufacturer or supplier for specific information regarding their resistance to chlorine gas.

Send your message to us

Insulating Fire Brick - High-Quality Insulation Brick Refractory Heat Resistant Building Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords