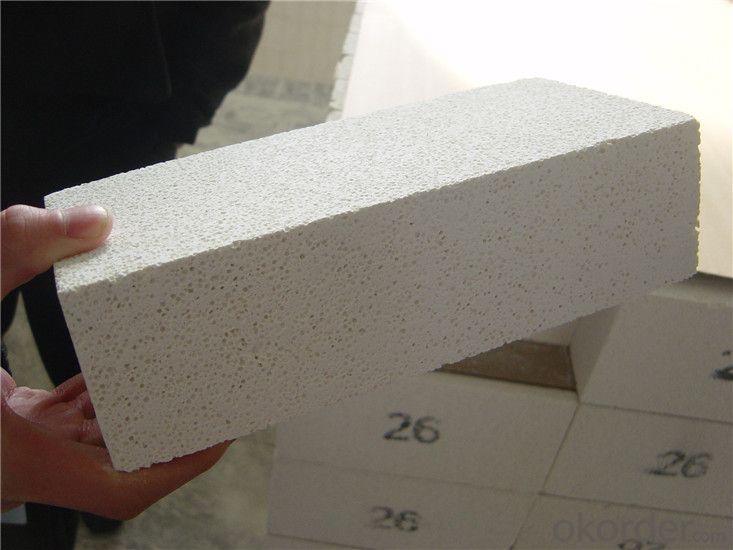

Insulating Fire Brick Lightweight Fire Clay

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Insulating Fire Brick Technical index

Product No. | IFB70 | IFB60 | IFB50 | IFB40 |

Al2O3 | 68%-72% | 58%-62% | 48%-52% | 38%-40% |

Refractoriness (°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1790 |

Bulk density (g/cm3) | 2.50-2.60 | 2.35-2.45 | 2.20-2.30 | 2.10-2.20 |

Apparent porosity (%) | 22 | 19-22 | 17-20 | 17-20 |

Cold Crushing strength (kg) | 480-510 | 450-480 | 430-450 | 390-430 |

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

- Q: Can insulating fire bricks be used in the construction of smelting ovens?

- Yes, insulating fire bricks can be used in the construction of smelting ovens. Insulating fire bricks are designed to have low thermal conductivity, which means they are excellent at retaining heat. This property makes them ideal for applications where high temperatures need to be maintained, such as smelting ovens. Smelting ovens are used to melt and refine various metals and minerals. These processes involve extremely high temperatures, and it is crucial to minimize heat loss to ensure efficient and effective smelting. Insulating fire bricks can help achieve this goal by providing excellent insulation and reducing heat loss. Insulating fire bricks are made from lightweight materials, such as ceramic fibers or expanded clay, which have high insulating properties. They are capable of withstanding temperatures up to 3000°F (1650°C), making them suitable for the extreme heat generated in smelting ovens. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is essential in smelting processes, which often involve heating and cooling cycles. Furthermore, insulating fire bricks are easy to work with and can be cut or shaped to fit specific dimensions or designs. This flexibility makes them highly adaptable for constructing smelting ovens of various shapes and sizes. In summary, insulating fire bricks are an excellent choice for the construction of smelting ovens due to their low thermal conductivity, high temperature resistance, thermal shock resistance, and ease of customization. They can help maintain high temperatures, reduce heat loss, and ensure efficient smelting processes.

- Q: Can insulating fire bricks be used for insulation in hot water tanks?

- Indeed, insulating fire bricks are suitable for insulating hot water tanks. Their superior thermal insulation properties deem them an optimal selection for such purpose. By utilizing these bricks, heat loss from the hot water tank can be efficiently prevented, consequently prolonging the water's temperature retention. Furthermore, these bricks exhibit exceptional durability and can endure high temperatures without fracturing or shattering, rendering them a dependable option for hot water tank insulation.

- Q: Are insulating fire bricks resistant to sound transmission?

- Insulating fire bricks, also known as refractory bricks, are primarily designed to withstand high temperatures and provide thermal insulation. While they are effective in reducing heat transfer, they are not specifically designed to resist sound transmission. Insulating fire bricks are made from materials such as clay, alumina, and silica, which are chosen for their ability to withstand high temperatures. These materials are dense and have a low porosity, which helps to prevent heat from passing through the bricks. However, sound waves can easily pass through solid materials, including insulating fire bricks, unless additional measures are taken to reduce sound transmission. To effectively reduce sound transmission, other soundproofing methods should be used in conjunction with insulating fire bricks. These can include adding additional layers of acoustic insulation or using sound barriers such as mass-loaded vinyl or acoustic panels. In summary, while insulating fire bricks are excellent for thermal insulation, they are not inherently resistant to sound transmission. Additional soundproofing measures should be taken to effectively reduce noise transmission in a given space.

- Q: Can insulating fire bricks be used for insulation in chemical plants?

- Yes, insulating fire bricks can be used for insulation in chemical plants. These bricks are made from lightweight materials with high insulating properties, such as ceramic fibers or refractory materials. They are designed to withstand high temperatures, making them suitable for use in environments with chemical processes that generate heat. Insulating fire bricks can be used in various applications within chemical plants, including lining for furnaces, reactors, kilns, and other equipment. Their excellent insulating properties help to reduce heat loss, conserve energy, and maintain optimal operating temperatures, ensuring the efficiency and safety of the chemical processes.

- Q: Can insulating fire bricks be used for insulation in smelters?

- Yes, insulating fire bricks can be used for insulation in smelters. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation properties, making them suitable for use in smelting operations where heat containment is crucial to optimize energy efficiency and protect the surrounding environment.

- Q: What are the main uses of insulating fire bricks?

- Insulating fire bricks, known as IFBs, are essential for applications requiring thermal insulation and heat resistance in high-temperature settings. These bricks are composed of lightweight materials like clay, silica, and alumina, engineered to endure extreme temperatures. A primary application of insulating fire bricks is the construction of kilns and furnaces. They line the walls, floors, and roofs of these high-temperature devices, delivering insulation to minimize heat loss and enhance energy efficiency. IFBs' insulating properties facilitate consistent and controlled temperatures inside kilns and furnaces, optimizing heating and cooling processes. Furthermore, insulating fire bricks are commonly employed in the construction of chimneys and flues. They withstand the corrosive effects of flue gases and endure the high temperatures produced during combustion. IFBs' insulation prevents heat transfer to surrounding structures, mitigating fire risks and ensuring the safety of chimneys and flues. Moreover, insulating fire bricks are frequently utilized in the manufacturing of fireplaces, pizza ovens, and other outdoor cooking equipment. These bricks retain heat within the cooking chamber, promoting even cooking and reducing fuel consumption. The insulating properties of IFBs also prevent the outer surfaces of these devices from overheating, decreasing the likelihood of accidental burns. Overall, insulating fire bricks are crucial for providing thermal insulation and heat resistance in high-temperature environments. Whether in kilns, furnaces, chimneys, or cooking equipment, these bricks play a vital role in maintaining efficient heating processes, ensuring safety, and conserving energy.

- Q: Can insulating fire bricks be used in ladle covers?

- Yes, insulating fire bricks can be used in ladle covers. Insulating fire bricks are designed to withstand high temperatures and provide thermal insulation. They are commonly used in various industrial applications, including ladle covers, to retain heat and prevent heat loss.

- Q: What sizes are insulating fire bricks available in?

- Insulating fire bricks are available in various sizes to cater to different needs and requirements. The sizes typically range from standard sizes like 9" x 4.5" x 2.5" to smaller sizes like 9" x 4.5" x 1". These standard sizes are commonly used in fireplaces, kilns, and furnaces. Additionally, larger sizes may be available for industrial applications that require thicker insulation. It is important to note that the availability of sizes may vary depending on the manufacturer or supplier, so it is recommended to check with them for specific size options.

- Q: How does the density of an insulating fire brick affect its performance?

- The performance of an insulating fire brick is heavily influenced by its density. Generally, bricks with higher density provide superior thermal insulation and mechanical strength compared to bricks with lower density. The density of an insulating fire brick directly affects its thermal insulation capabilities. Bricks with higher density have smaller pores and a more compact structure, resulting in better insulation against heat transfer. This means that the brick can effectively resist the transfer of heat, maintaining a consistent temperature within the structure it is used in. On the other hand, bricks with lower density have larger pores and a less compact structure, allowing for more heat transfer and reducing their insulating capabilities. Apart from thermal insulation, the density of an insulating fire brick also impacts its mechanical strength. Bricks with higher density generally have greater structural integrity and resistance to mechanical stress. This means that they are more reliable and durable, capable of withstanding higher temperatures and physical pressures without cracking or breaking. Conversely, bricks with lower density may be more fragile and prone to damage, limiting their performance in harsh conditions. Therefore, when selecting an insulating fire brick for a specific application, it is important to consider its density. A balance must be struck between achieving optimal thermal insulation and mechanical strength. Factors such as the desired level of insulation, operating temperature, and structural requirements of the application should be taken into account to determine the appropriate density of the insulating fire brick for maximum performance.

- Q: Do insulating fire bricks require a refractory mortar for installation?

- Yes, insulating fire bricks typically require a refractory mortar for proper installation. Insulating fire bricks are lightweight and have high insulating properties, making them ideal for applications where thermal efficiency is important. However, due to their lightweight nature, they can be more fragile and prone to cracking or breaking under stress. Using a refractory mortar specifically designed for high-temperature applications helps ensure a strong and durable bond between the bricks. Refractory mortars are formulated to withstand high temperatures and provide excellent adhesion and thermal expansion properties. This mortar helps to create a solid and secure structure by filling in gaps between the bricks and providing additional support. Without the use of refractory mortar, insulating fire bricks may not be properly secured and could shift or separate over time, compromising the integrity of the installation. Additionally, the absence of refractory mortar may result in reduced thermal efficiency due to increased heat loss through gaps and spaces between the bricks. Therefore, it is highly recommended to use a refractory mortar when installing insulating fire bricks to ensure a strong and long-lasting construction.

Send your message to us

Insulating Fire Brick Lightweight Fire Clay

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords