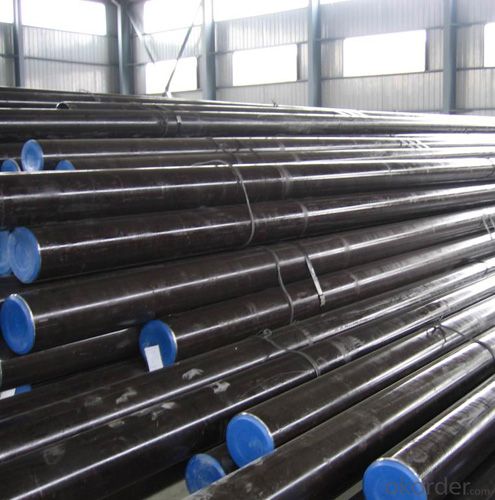

High Quality Hot rolled Bearing Special Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot rolled Bearing Special Steel Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Our products have been used in all kinds of areas, such as aviation, aerospace, navigation, nuclear, energy, chemical industry, electronic information, petrochemical, automotive, instrument and meter, Communication ,transportation, and medical instruments, etc. Bearing ring,steel rolling mill ,machinery, 100Cr6 bearing steel ball is widely used in high-speed and low-noise bearing, bicycle, motorcycle, automobile, bags, electronics.

Product Advantages:

OKorder's Hot rolled Bearing Special Steel Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Bearing Steel

1. Dimensional sizes: Thickness: 14~100mm.Length:3000~5800mm,Diameter :14-500mm

2.Chemical composition:

C | Si | Mn | Cr | Ni | Cu |

Equal or less than | |||||

0.95-1.05 | 0.15-0.35 | 0.20-0.40 | Cr:1.30-1.65 | 0.30 | 0.25 |

3. Grade: SAE51200/ GCr15 / 100cr6

4. Heat Treatment:

Soft annealing: heat to 680-720°C, cool slowly.

Hardness after annealing: Max. 241 HB

Hardening: 820 - 850 °C

Normalizing temperature: 840-880°C

Tempering: 540-680°C

5. Surface requirements: Black, grinding, bright, polish

6. Characters:

1) Comprehensive properties

2) Good performance in cutting and processing after spheroids annealing

3) High hardness and homogenization after quenching and tempering

4) High abrasive resistance and fatigue resistance

7. Payment terms: T/T or L/C at sight

Usage & Applications of Bearing Steel

Our products have been used in all kinds of areas, such as aviation, aerospace, navigation, nuclear, energy, chemical industry, electronic information, petrochemical, automotive, instrument and meter, Communication ,transportation, and medical instruments, etc. Bearing ring,steel rolling mill ,machinery, 100Cr6 bearing steel ball is widely used in high-speed and low-noise bearing, bicycle, motorcycle, automobile, bags, electronics.

Packaging & Delivery of Bearing Steel

Mark: Heat No. will be cold stamped and Steel grade, diameter (mm), length (mm), and the manufacturer LOGO and weight (kg) is painted.

Standard seaworthy packing or as customer required

Delivery time: Within 30 days after order is confirmed.

Note:

1. According to national standard (GB) for our products, if not, supply according to national standards (GB) or agreement.

2. We can not only provide electric furnace +LF+VD and electro-slag re-melting (ESR)steel forging materials, but also forging products of piece, bar, etc.

3. Our company is equipped with roll equipment and can provide our customers with roll billets or finished.

4. Please send us your detailed specifications when inquire. We will reply to you ASAP.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can special steel be used in the production of gears?

- Yes, special steel can be used in the production of gears. Special steels are often preferred for gear manufacturing due to their high strength, durability, and wear resistance properties. They can withstand heavy loads, high temperatures, and provide excellent performance in various industries such as automotive, aerospace, and machinery.

- Q: What are the different types of corrosion-resistant steel?

- There are several different types of corrosion-resistant steel, including stainless steel, galvanized steel, weathering steel, and nickel alloy steel.

- Q: What are the different forming techniques for special steel?

- Some of the different forming techniques for special steel include hot forging, cold forging, extrusion, rolling, and casting. These techniques allow for the shaping and manipulation of the steel to meet specific requirements, such as strength, durability, and dimensional accuracy. Each technique has its own advantages and can be chosen based on the desired outcome and the characteristics of the special steel being used.

- Q: How does special steel contribute to the pharmaceutical aftermarket industry?

- The pharmaceutical aftermarket industry greatly relies on special steel, which offers numerous benefits that enhance the efficiency and quality of pharmaceutical products. Firstly, special steel's resistance to corrosion and wear makes it ideal for manufacturing pharmaceutical equipment like tanks, vessels, and pipelines. This resistance guarantees the equipment's integrity and prevents any contamination of pharmaceutical products. Furthermore, special steel possesses outstanding heat resistance, enabling it to withstand high temperatures without deformation or degradation. This is especially crucial in pharmaceutical manufacturing processes involving heat, such as sterilization or drying. Special steel's heat resistance ensures the equipment remains stable and reliable, ensuring the safety and effectiveness of pharmaceutical products. Moreover, special steel is renowned for its strength and durability, making it capable of enduring rigorous usage in the pharmaceutical industry. This is vital in the aftermarket industry, where pharmaceutical equipment often undergoes frequent repairs or modifications. The strength and durability of special steel facilitate easy maintenance and repair, reducing downtime and costs for pharmaceutical companies. Additionally, special steel offers excellent hygiene properties, as it can be easily cleaned and sanitized. This is of utmost importance in the pharmaceutical industry, where stringent hygiene standards are crucial to prevent contamination or cross-contamination of pharmaceutical products. Special steel's ease of cleaning and sanitization ensures the equipment remains free from potential sources of contamination, thereby preserving the integrity and quality of the products. In summary, special steel significantly contributes to the pharmaceutical aftermarket industry by providing corrosion resistance, heat resistance, strength, durability, and excellent hygiene properties. These characteristics ensure the integrity, safety, and effectiveness of pharmaceutical products, while also minimizing maintenance costs and downtime for pharmaceutical companies. Thus, special steel plays a pivotal role in the overall efficiency and success of the pharmaceutical aftermarket industry.

- Q: How does special steel perform in high-temperature oxidation resistance?

- Special steel is specifically engineered to possess exceptional resistance to oxidation at high temperatures. This kind of steel incorporates alloying components like chromium, aluminum, and silicon, which generate a protective layer of oxide on the surface when subjected to extreme heat. This oxide layer acts as a barrier, preventing further oxidation and corrosion of the steel. The capacity of special steel to withstand high-temperature oxidation is of utmost importance in scenarios where the material is exposed to intense heat and oxidation, for instance, in gas turbines, heat exchangers, and furnaces. The protective oxide layer aids in preserving the strength and integrity of the steel, even under rigorous conditions. Moreover, special steel also showcases remarkable resistance to creep at high temperatures. Creep refers to the gradual distortion of a material under a consistent load and elevated temperatures. The distinctive composition of special steel grants it the ability to resist creep deformation, thereby enhancing its overall performance and dependability in environments with high temperatures. In conclusion, special steel exhibits exceptional performance in terms of resistance to high-temperature oxidation due to its alloying elements and the formation of a protective oxide layer. Its capability to resist oxidation and maintain its structural integrity at elevated temperatures makes it the preferred choice for numerous industrial applications.

- Q: How does precipitation hardening enhance the strength of special steel?

- Precipitation hardening is a heat treatment process that enhances the strength of special steel by creating small, uniformly dispersed particles within the metal matrix. These particles act as obstacles to dislocation movement, making it more difficult for them to slide past each other and deform the material. This results in increased strength, hardness, and resistance to wear and fatigue, making the steel suitable for various demanding applications.

- Q: What are the main applications of special steel in the chemical industry?

- Special steel is widely used in the chemical industry due to its excellent properties such as corrosion resistance, high temperature resistance, and strength. It is primarily used in the construction of chemical processing equipment, including reactors, pipes, valves, and storage tanks. Special steel ensures the safe and efficient handling of corrosive chemicals, as well as the prevention of leaks and contamination. Additionally, it is utilized in the production of catalysts, which play a crucial role in various chemical reactions. Overall, special steel enables the chemical industry to maintain high product quality, operational efficiency, and safety standards.

- Q: How is special steel tested for quality control?

- Special steel is tested for quality control through various methods, such as mechanical testing, chemical analysis, and non-destructive testing. Mechanical testing involves assessing the steel's strength, hardness, toughness, and other mechanical properties through techniques like tensile, impact, and hardness testing. Chemical analysis is performed to ensure the steel meets the desired composition and impurity levels, utilizing techniques like spectrometry. Non-destructive testing methods, like ultrasonic, magnetic particle, and visual inspection, are used to detect any surface or internal defects in the steel. These rigorous testing procedures ensure that special steel meets the required quality standards before it is used in various applications.

- Q: What are the main characteristics of pressure vessel steel forgings?

- Pressure vessel steel forgings possess several key features that render them suitable for utilization in pressure vessels. Firstly, these forgings are renowned for their exceptional strength and toughness. This attribute is of utmost importance as pressure vessels typically encounter significant internal pressure, necessitating steel capable of withstanding such force without deformation or rupture. Meticulous design and manufacturing ensure that the forgings possess the requisite strength and toughness to endure these pressures. Secondly, pressure vessel steel forgings exhibit remarkable resistance to corrosion. Given that pressure vessels frequently house corrosive fluids or gases, it becomes imperative for the steel employed in their construction to possess corrosion resistance. This feature guarantees the durability and dependability of the pressure vessel. The steel forgings are often crafted with specific alloying elements that enhance their resistance to corrosion. A further notable characteristic of pressure vessel steel forgings lies in their ability to retain their mechanical properties at elevated temperatures. Pressure vessels may be subjected to heightened temperatures due to the nature of the processes or fluids they contain. The forgings are designed to maintain their strength and toughness even in these high-temperature conditions, thereby ensuring the safety and reliability of the pressure vessel. Moreover, pressure vessel steel forgings typically undergo stringent quality control measures during their manufacturing process. This is essential to ensure that the forgings meet the prescribed standards and specifications for pressure vessel applications. The manufacturing process incorporates comprehensive inspections, testing, and documentation to guarantee compliance with the necessary quality and safety requirements. In summary, the primary characteristics of pressure vessel steel forgings encompass high strength and toughness, exceptional corrosion resistance, the ability to endure high temperatures, and stringent quality control measures. These attributes render pressure vessel steel forgings ideal for utilization in pressure vessels, providing the requisite strength, reliability, and safety demanded by such applications.

- Q: What are the main factors affecting the fatigue strength of special steel?

- The main factors affecting the fatigue strength of special steel include the material's microstructure, surface condition, heat treatment, and loading conditions. Additionally, factors such as environmental conditions, stress concentration, and the presence of defects or imperfections can also influence the fatigue strength of special steel.

Send your message to us

High Quality Hot rolled Bearing Special Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords