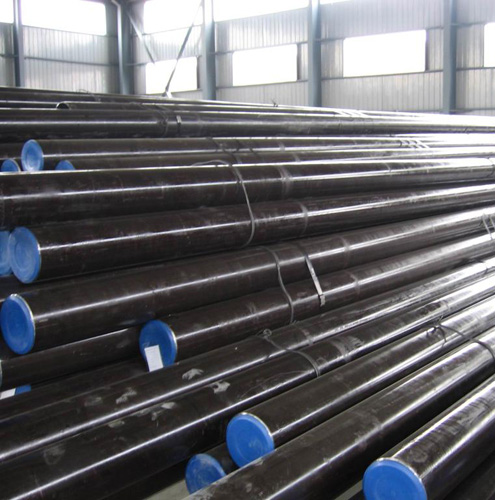

Hot rolled High Quality Bearing Special Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot rolled Bearing Special Steel Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Our products have been used in all kinds of areas, such as aviation, aerospace, navigation, nuclear, energy, chemical industry, electronic information, petrochemical, automotive, instrument and meter, Communication ,transportation, and medical instruments, etc. Bearing ring,steel rolling mill ,machinery, 100Cr6 bearing steel ball is widely used in high-speed and low-noise bearing, bicycle, motorcycle, automobile, bags, electronics.

Product Advantages:

OKorder's Hot rolled Bearing Special Steel Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Bearing Steel

1. Dimensional sizes: Thickness: 14~100mm.Length:3000~5800mm,Diameter :14-500mm

2.Chemical composition:

C | Si | Mn | Cr | Ni | Cu |

Equal or less than | |||||

0.95-1.05 | 0.15-0.35 | 0.20-0.40 | Cr:1.30-1.65 | 0.30 | 0.25 |

3. Grade: SAE51200/ GCr15 / 100cr6

4. Heat Treatment:

Soft annealing: heat to 680-720°C, cool slowly.

Hardness after annealing: Max. 241 HB

Hardening: 820 - 850 °C

Normalizing temperature: 840-880°C

Tempering: 540-680°C

5. Surface requirements: Black, grinding, bright, polish

6. Characters:

1) Comprehensive properties

2) Good performance in cutting and processing after spheroids annealing

3) High hardness and homogenization after quenching and tempering

4) High abrasive resistance and fatigue resistance

7. Payment terms: T/T or L/C at sight

Packaging & Delivery of Bearing Steel

Mark: Heat No. will be cold stamped and Steel grade, diameter (mm), length (mm), and the manufacturer LOGO and weight (kg) is painted.

Standard seaworthy packing or as customer required

Delivery time: Within 30 days after order is confirmed.

Note:

1. According to national standard (GB) for our products, if not, supply according to national standards (GB) or agreement.

2. We can not only provide electric furnace +LF+VD and electro-slag re-melting (ESR)steel forging materials, but also forging products of piece, bar, etc.

3. Our company is equipped with roll equipment and can provide our customers with roll billets or finished.

4. Please send us your detailed specifications when inquire. We will reply to you ASAP.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: How does special steel contribute to the overall economy?

- Special steel contributes to the overall economy in several ways. Firstly, it plays a crucial role in various industries such as automotive, construction, and manufacturing, where it is used for producing high-performance components and structures. This fosters innovation, enhances productivity, and drives economic growth. Additionally, the production and processing of special steel create employment opportunities, both directly and indirectly, stimulating job growth and income generation. Moreover, special steel exports contribute to trade balance and foreign exchange earnings, further bolstering the economy. Overall, the utilization of special steel in diverse sectors strengthens industrial competitiveness, supports economic development, and fuels economic prosperity.

- Q: How is special steel manufactured?

- Special steel is manufactured through a process called steelmaking, which involves melting iron ore along with other alloying elements such as chromium, nickel, or molybdenum, to achieve the desired properties. The molten steel is then refined, cast into various shapes, and subjected to heat treatment to enhance its strength, hardness, and other mechanical properties.

- Q: Can special steel be used in marine environments?

- Yes, special steel can be used in marine environments. Special steel alloys, such as stainless steel or corrosion-resistant steel, are specifically designed to withstand the harsh conditions of saltwater and other corrosive elements found in marine environments. These alloys have excellent resistance to corrosion, erosion, and pitting, making them suitable for various marine applications, including shipbuilding, offshore structures, and marine equipment.

- Q: Is special steel suitable for electrical and electronic applications?

- Yes, electrical and electronic applications can benefit from the use of special steel. Special steel refers to steel alloys that are specifically designed to have certain properties or characteristics that make them suitable for specific applications. When it comes to electrical and electronic applications, special steel offers several advantages. One of the main requirements for electrical and electronic applications is high electrical conductivity. Although steel is not known for its electrical conductivity, certain special steel alloys can be engineered to have improved electrical conductivity. For example, by adding elements like nickel or copper to stainless steel, its electrical conductivity can be enhanced, making it suitable for applications where efficient flow of electrical current is needed. Magnetic properties are also important for electrical and electronic applications. Some special steel alloys exhibit exceptional magnetic properties, making them ideal for use in transformers, motors, and generators. These alloys possess qualities such as high magnetic permeability, low coercivity, and low hysteresis losses, which are crucial for efficient energy transfer and minimal power loss. Additionally, special steel provides excellent corrosion resistance, which is essential for electrical and electronic equipment that may come into contact with moisture or harsh environments. Stainless steel, for instance, is highly resistant to corrosion, ensuring the longevity and reliability of the equipment. In conclusion, special steel can be suitable for electrical and electronic applications when it possesses the necessary electrical conductivity, magnetic properties, and corrosion resistance. Manufacturers can ensure the performance, durability, and reliability of electrical and electronic equipment by selecting the appropriate special steel alloy.

- Q: What are the main characteristics of magnetic steel forgings?

- Magnetic steel forgings exhibit several key characteristics that make them highly desirable in various industries. Firstly, magnetic steel forgings possess excellent magnetic properties, allowing them to be easily magnetized and demagnetized. This property makes them suitable for applications where magnetism is required, such as in electrical motors and generators. Secondly, magnetic steel forgings possess high strength and durability. Due to the forging process, the steel is compressed and shaped, resulting in a dense and uniform microstructure. This enhances the mechanical properties of the steel, including its tensile strength, impact resistance, and fatigue strength. As a result, magnetic steel forgings can withstand heavy loads and harsh operating conditions, making them ideal for use in demanding applications such as automotive components, industrial machinery, and aerospace parts. Another characteristic of magnetic steel forgings is their excellent corrosion resistance. The forging process helps to refine the grain structure of the steel, making it less susceptible to corrosion and oxidation. This property is crucial in industries where components are exposed to corrosive environments or high temperatures, such as marine applications or oil and gas equipment. Furthermore, magnetic steel forgings offer good machinability and weldability. The forging process not only enhances the mechanical properties of the steel but also improves its machinability, allowing it to be easily shaped and modified into intricate designs. Additionally, magnetic steel forgings can be readily welded without compromising their integrity, providing flexibility in manufacturing and assembly processes. Lastly, magnetic steel forgings exhibit excellent dimensional stability. The forging process involves controlled heating and cooling, which helps to minimize dimensional changes and distortions. This ensures that the final product maintains its shape and dimensions, enabling precise fit and compatibility with other components. In summary, the main characteristics of magnetic steel forgings include excellent magnetic properties, high strength and durability, corrosion resistance, good machinability and weldability, and dimensional stability. These characteristics make magnetic steel forgings highly versatile and widely used in various industries, contributing to their overall success and popularity.

- Q: How does special steel perform in high-temperature creep resistance?

- Special steel is known for its exceptional performance in high-temperature creep resistance. Creep refers to the tendency of a material to deform or strain under constant stress when exposed to elevated temperatures. In such conditions, ordinary steels may exhibit significant creep, leading to a loss of mechanical properties and potential failure. However, special steels are specifically designed to withstand high-temperature creep, making them ideal for applications where resistance to time-dependent deformation is critical. These steels are often alloyed with elements such as chromium, molybdenum, and vanadium, which enhance their high-temperature properties. The alloying elements in special steels form stable carbides and nitrides, which act as strengthening agents, inhibiting grain growth, and preventing dislocation movement. This results in improved creep resistance and structural stability even at extreme temperatures. Additionally, special steels often undergo heat treatment processes such as quenching and tempering, which further enhance their creep resistance and overall mechanical performance. Furthermore, the microstructure of special steels is carefully controlled during the manufacturing process to ensure optimal creep resistance. Fine-grained structures with a high density of precipitates or second-phase particles are typically developed, which hinder dislocation movement and improve creep strength. In summary, special steels exhibit exceptional high-temperature creep resistance due to their alloying elements, heat treatment processes, and controlled microstructures. These steels can reliably withstand prolonged exposure to elevated temperatures without significant deformation or loss of mechanical properties, making them invaluable in industries such as aerospace, power generation, and petrochemicals where high-temperature applications are common.

- Q: What are the main applications of special steel in the chemical industry?

- Special steel is widely used in the chemical industry due to its excellent properties such as corrosion resistance, high temperature resistance, and strength. It is primarily used in the construction of chemical processing equipment, including reactors, pipes, valves, and storage tanks. Special steel ensures the safe and efficient handling of corrosive chemicals, as well as the prevention of leaks and contamination. Additionally, it is utilized in the production of catalysts, which play a crucial role in various chemical reactions. Overall, special steel enables the chemical industry to maintain high product quality, operational efficiency, and safety standards.

- Q: Can special steel be used in the production of surgical instruments?

- Yes, special steel can be used in the production of surgical instruments. Special steel, such as stainless steel, is commonly used in the manufacturing of surgical instruments due to its durability, corrosion resistance, and ability to withstand sterilization processes. This type of steel ensures that surgical instruments maintain their integrity and functionality, making them suitable for use in medical procedures.

- Q: How does special steel perform in high-temperature creep conditions?

- Special steel performs well in high-temperature creep conditions due to its high strength, excellent resistance to deformation, and superior heat resistance properties. It can withstand prolonged exposure to elevated temperatures without significant deformation or structural failure, making it an ideal choice for applications in industries such as aerospace, power generation, and petrochemicals.

- Q: How is special steel used in the marine manufacturing process?

- Special steel is used in the marine manufacturing process for various applications, such as constructing ship hulls, propeller shafts, and offshore platforms. Its high strength, corrosion resistance, and ability to withstand harsh marine environments make it an ideal material choice. Additionally, special steel's excellent weldability and machinability ensure efficient and reliable production in the marine industry.

Send your message to us

Hot rolled High Quality Bearing Special Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords