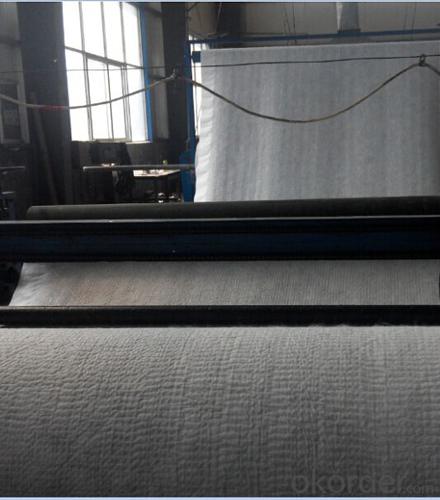

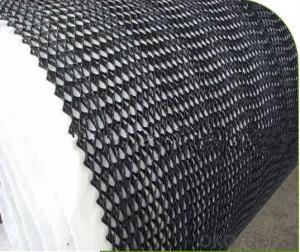

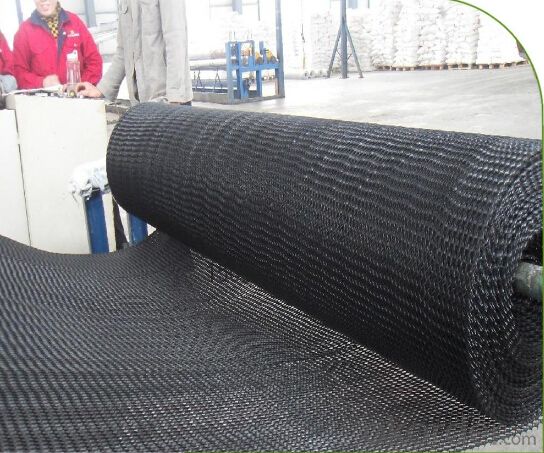

HDPE Three-Dimension Compound Drainage Net

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Three-Dimension Compound Drainage Net

Introuduction :

geonet can be used in the soft soil stabilization, base reinforcement, embankments over soft soils, seacoast slope protection and reservoir bottom reinforcement, etc

It prevents the slope rock from falling down ,which avoids the hurt to the human beings and the vehicle on the road; It prevents the road dregs packed by geonet from being washed away ,avoids the roadbed distortion and improves the stability of the roadbed; laying the geonet reinforces the road surface ,avoids development of the reflection crack. As reinforcing material of filling soil in retaining walls, it disperses the earth body stress and restricts the side-displacement. The stone cage, made of geonet, can prevent erosion ,collapsing and lost of water and soil when being used in dyke and rock slope protetion

Application:

Water Lagoons

Lagooning and Water Treatment Tanks,

Reservoirs, Liquid

Waste Ornamental Ponds,

Golf Courses

Drainage and Filtration

Landfill CappingTailing ponds,

Leach miningVertical Barriers

Erosion ControlTunnels

Linear and Surface Works

Consolidation of Margins Building – Parking:

Features:

1)Excellent drainage function, can bear long time hige press load

2)High tensile and shear strength

3Reduce the rate geotextile embedding into the core of geonet, can protect long time stable water conductivity

4)Tri-dimension composite geonet for drainage can bear more than 2000kpa compression load

5)Its anti-compression capacity is much larger than common geonet for drainage

6) Certificate :ISO14001:2004, ISO9001:2008

Specifications and technical parameters:

Drainage network core | units | Specification | ||||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 | |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 | |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 | |

Elongation | % | 50 | 50 | 50 | 50 | |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 | |

Geotextile | g/m2 | Heavier grades of geotextiles can be bonded to geonet on request | ||||

Usages:

In the railway, highway and other transportation infrastructure, drainage system safety and the service life

of the project and its have inseparable relationship, in which the geotextile material is an important part

of drainage system, the drainage effect of 3D composite drainage net is particularly notable. mainly

used for tunnels, municipal engineering, reservoir, revetment in drainage engineering.

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

- Q: What are the different warranty options available for earthwork products?

- The different warranty options available for earthwork products vary depending on the manufacturer and the specific product. However, common warranty options include limited warranties, extended warranties, and lifetime warranties. These warranties typically cover defects in materials and workmanship and may also include coverage for specific damages or failures. It is important to carefully review the terms and conditions of each warranty to understand what is covered and any exclusions or limitations that may apply.

- Q: Vehicle engineering civil engineering machinery engineering and automation materials which is better Ah are doing

- We recommend choosing automation

- Q: Such as steel, cement, coarse aggregate, fine aggregate, anchor. The The Is it a concrete definition?

- There are three large series of buildings, civil, electrical, plumbing, civil steel reinforced concrete, is called 3 large, masonry, commodity concrete, turnover, waterproof, paint, flooring, small materials

- Q: How do earthwork products contribute to wastewater treatment systems?

- Earthwork products, such as geotextiles and geosynthetics, play a vital role in wastewater treatment systems. These products are used for filtration, separation, and reinforcement purposes, ensuring the proper functioning and efficiency of these systems. Geotextiles act as a barrier, preventing the clogging of drainage systems by filtering out suspended particles and allowing the water to flow freely. Geosynthetics, on the other hand, provide reinforcement and stability to structures like retaining walls, embankments, and lagoons, increasing the overall durability and longevity of the wastewater treatment system. Therefore, earthwork products are essential in maintaining the effectiveness and sustainability of wastewater treatment systems.

- Q: What are the different weight options available in earthwork products?

- The weight options available in earthwork products can vary depending on the specific product and its intended use. Some common weight options include lightweight, medium weight, and heavy-duty. However, it is important to note that the weight of earthwork products can be customized to meet the specific requirements and preferences of the customer.

- Q: How do geopipes help in stormwater infiltration systems?

- Geopipes help in stormwater infiltration systems by effectively capturing and transporting stormwater runoff to designated infiltration areas. Their perforated design allows for efficient water drainage and prevents clogging, ensuring the smooth infiltration of stormwater into the ground. Geopipes also help distribute the water evenly across the infiltration area, minimizing the risk of localized flooding or erosion. Overall, geopipes play a crucial role in enhancing the functionality and effectiveness of stormwater infiltration systems.

- Q: Can earthwork products be used for creating outdoor art installations?

- Yes, earthwork products can certainly be used for creating outdoor art installations. Earthwork materials such as soil, rocks, and natural elements can be sculpted, arranged, or manipulated to create unique and visually captivating outdoor art installations. These installations can range from land art and environmental sculptures to temporary installations and public art projects. Earthwork products offer artists a versatile and sustainable medium to express their creativity in outdoor spaces.

- Q: Can earthwork products be used in coastal restoration projects?

- Yes, earthwork products can be used in coastal restoration projects. Earthwork products such as soil, rocks, and sediments can be utilized to build or reinforce coastal structures like dunes, berms, and breakwaters. These materials are often beneficial in stabilizing shorelines, preventing erosion, and creating habitats for marine life. Additionally, earthwork products can be used to fill in areas that have been eroded or damaged by storms, helping restore coastal ecosystems and protect against future erosion.

- Q: Can earthwork products be used in agricultural applications?

- Yes, earthwork products can be used in agricultural applications. They can be used for various purposes such as land leveling, soil stabilization, erosion control, and drainage management. For example, products like geotextiles, geomembranes, and geocells can be used to reinforce soil, prevent erosion, and improve water containment in agricultural fields. Additionally, earthwork machinery such as excavators and bulldozers can be used for activities like land clearing and terracing, which are essential in agricultural practices.

- Q: How do geogrids help in soil reinforcement in earthwork projects?

- Geogrids help in soil reinforcement in earthwork projects by providing additional tensile strength to the soil, thereby improving its stability and preventing soil erosion or failure. They are typically made of high-strength synthetic materials and are placed within the soil to distribute loads and limit the movement of soil particles. This reinforcement allows for the construction of steeper slopes, reduction in the amount of excavation, and overall enhancement of the soil's load-bearing capacity.

Send your message to us

HDPE Three-Dimension Compound Drainage Net

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords