Sodium Bentonite Geosynthetic Clay Liner(GCL)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

sodium Bentonite Geosynthetic Clay Liner(GCL)

1,Introduction

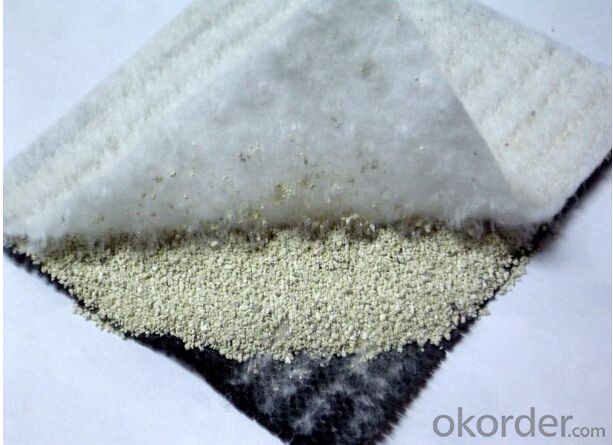

bentonite geotextile clayliner is composed of 3 levels. The upper level and the lower level are woven geotextile and non woven textile.

The middle level is bentonite grains, which are carefully selected crude and filled in between the two levels after special processing.

The bentonite grain in GCL made by this method does not flow in a fixed direction. It distributes evenly and forms waterproof layer, owning excellent waterproof effect.

2,Feature

(1) A permanent waterproof performance, and excellent water seepage performance, impermeability hydrostatic pressure up to 1.0MPa above, permeability coefficient 5 *10-9cm / s. Because the Department of Natural sodium bentonite inorganic materials, even after a long time or the surrounding environment changes, aging or corrosion does not occur.

(2) Has all the characteristics of geotextile material, such as separation, reinforcement, protection, filtration, simple construction and unrestricted construction environment temperature below 0 0 C also be construction. Just when construction GCL waterproof blanket tile on the floor, when the elevation or slope construction, with nails and washers to secure it, as required, can overlap.

(3) Easy to repair; Even after water (seepage) end of construction, such as waterproof layer accident damage, as long as the site of the damage to be a simple fix, can ever regain perfect waterproof performance.

(4)green: Bentonite is a natural inorganic material, harmless, non-toxic, no particular impact on the environment, with good environmental performance.

(5) simple construction period is short: and other waterproof materials, the construction is relatively simple, does not require heating and paste. Product width up to 6 meters, with international geotextile (film) to match the size, greatly improving the efficiency of construction.

(6) Integrated waterproof materials and objects: When sodium bentonite water, with 20-28 times the capacity expansion, even if the concrete structure vibration and settlement, bentonite GCL can repair cracks in the concrete surface less than 2mm.

3,Application

(1)Municipal engineering, underground engineering subways, buildings and roofs reservoir seepage.

(2)Environmental sanitation, solid waste landfills, sewage treatment plants, industrial waste.

(3)water, rivers, lakes and reservoirs dam seepage, plugging, reinforcement.

(4)Garden artificial lake golf course pond seepage and so on.

(5)Petrochemical, mining and other areas of engineering seepage, leakage, etc.

4,Specification of Geosynthetic Clay Liner(GCL) for anti-seepage

PROPERTIES | Test Method | Typical Value |

BENTONITE PROPERTIES | ||

Bentionite Swell Index | ASTM D 5890 | ≥24ml/2g |

Bentionite Fluid Loss | ASTM D 5891 | ≤18ml |

Finished GCL PROPERTIES | ||

Bentionite Mass/Unit Area | ASTM D 5993 | ≥3.6kg/sq.m |

Peel Strength | ASTM D 6496 | ≥400N/m |

Grab Strength | ASTM D 6768 | ≥6kN/m |

Thickness | ASTM D 5199 | ≥6mm |

Permeability | ASTM D 5084 | ≤5.0×10-11m/sec |

Index Flux | ASTM D 5887 | ≤1.0×10-8m3/m2/sec |

Geotextile PROPERTIES | ||

Non-Woven Geotextile Mass | ASTM D 5261 | ≥200g/sq.m |

Woven Geotextile Mass | ASTM D 5261 | ≥110g/sq.m |

ROLL DIMENSIONS | ||

Width | Normal | 5.8m |

Length | Normal | 30m |

Package | Normal | PE Film |

PROPERTIES | Test Method | Typical Value |

BENTONITE PROPERTIES | ||

Bentionite Swell Index | ASTM D 5890 | ≥24ml/2g |

Bentionite Fluid Loss | ASTM D 5891 | ≤18ml |

Finished GCL PROPERTIES | ||

Bentionite Mass/Unit Area | ASTM D 5993 | ≥3.6kg/sq.m |

Peel Strength | ASTM D 6496 | ≥400N/m |

Grab Strength | ASTM D 6768 | ≥6kN/m |

Thickness | ASTM D 5199 | ≥6mm |

Permeability | ASTM D 5084 | ≤5.0×10-11m/sec |

Index Flux | ASTM D 5887 | ≤1.0×10-8m3/m2/sec |

Geotextile PROPERTIES | ||

Non-Woven Geotextile Mass | ASTM D 5261 | ≥200g/sq.m |

Woven Geotextile Mass | ASTM D 5261 | ≥110g/sq.m |

ROLL DIMENSIONS | ||

Width | Normal | 5.8m |

Length | Normal | 30m |

Package | Normal | PE Film |

Matching Accessories:

1.Bentonite sealing powder. It is the identical to the bentonite grain of the GCL used as the lap between GCL.

Package: 50kg per woven geotextile bag.

Applications1.waterproof for rooftop garden,basement and so on;

2.waterproof for underground,railway,city highway,oil drilling and so on;

3.Anti-seepage project of mud and stone reinforce

4.desert and environment improvement,trash stuff zone,artificial lake and artificial sight and so on;

5.reservoir,dam,irrigation channel and so on;

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: How do geotextile tubes work in dewatering applications?

- Geotextile tubes work in dewatering applications by containing and separating solids from water. The tubes are filled with slurry, which allows water to pass through the geotextile fabric while retaining the solid particles. As the water drains, the solids are left behind, resulting in dewatering of the site or containment of sediments.

- Q: Can geosynthetics be used for bridge abutment reinforcement?

- Yes, geosynthetics can be used for bridge abutment reinforcement. Geosynthetics such as geotextiles, geogrids, and geocomposites are commonly used to enhance the stability and strength of bridge abutments. They can provide soil reinforcement, prevent soil erosion, and improve overall performance and durability of the abutment structure.

- Q: How do geosynthetic clay liners contribute to environmental containment?

- Geosynthetic clay liners (GCLs) contribute to environmental containment by providing a barrier against the migration of contaminants. The clay component of GCLs possesses excellent hydraulic conductivity, swelling capacity, and self-sealing properties. These characteristics allow GCLs to effectively restrict the movement of liquids and gases, preventing the spread of pollutants into surrounding soil and water sources. Additionally, GCLs act as a physical barrier, minimizing the risk of leakage and protecting the environment from potential harm.

- Q: How are geosynthetics used in drainage systems?

- Geosynthetics are used in drainage systems to improve their performance and efficiency. They are often used as filters to prevent soil particles from clogging the drainage pipes, allowing water to flow freely. Geosynthetics can also be used as separators to prevent the mixing of different soil layers, ensuring proper drainage. Additionally, they can be used as reinforcements to enhance the stability and durability of the drainage system, preventing soil erosion and maintaining its integrity.

- Q: Are earthwork products resistant to impact and abrasion?

- Yes, earthwork products are generally resistant to impact and abrasion due to their durable nature and composition.

- Q: How do geosynthetic meshes help in soil stabilization for embankments?

- Geosynthetic meshes help in soil stabilization for embankments by providing reinforcement and confinement to the soil, improving its strength and stability. These meshes act as a barrier against soil erosion, preventing the loss of soil particles and maintaining the embankment's integrity. The meshes also distribute the applied loads more evenly across the embankment, reducing stress concentrations and the potential for slope failure. Additionally, geosynthetic meshes allow for efficient drainage of excess water, preventing saturation and maintaining the embankment's stability in wet conditions.

- Q: What are the benefits of using geogrids in reinforced soil structures?

- Using geogrids in reinforced soil structures offers several benefits. Firstly, geogrids provide enhanced stability to the soil by distributing and transferring loads, reducing the risk of slope failure or settlement. They can also increase the bearing capacity of the soil, allowing for the construction of structures on weak or soft ground. Additionally, geogrids improve the overall performance of the reinforced soil structure by preventing soil erosion and retaining the structure's shape. They also minimize differential settlement, which helps in maintaining the integrity and longevity of the structure. Furthermore, geogrids are cost-effective compared to traditional construction methods as they require less excavation, backfill material, and labor. They are easy to install, lightweight, and can be customized to fit specific project requirements. Overall, the use of geogrids in reinforced soil structures provides increased stability, improved performance, cost savings, and a longer lifespan for the structure.

- Q: Can earthwork products be used in underground utility installations?

- Yes, earthwork products can be used in underground utility installations. Earthwork products such as geotextiles, geogrids, and geomembranes are commonly used to enhance the stability, strength, and longevity of underground utility installations. These products help in preventing soil erosion, providing reinforcement to the soil structure, and improving overall performance and durability of underground utilities.

- Q: What are the advantages of using geosynthetic materials in canal lining projects?

- There are several advantages to using geosynthetic materials in canal lining projects. Firstly, geosynthetics provide excellent resistance to erosion and chemical degradation, ensuring long-term durability of the canal lining. Secondly, these materials offer superior hydraulic performance, allowing for efficient water flow and reduced seepage. Additionally, geosynthetics are lightweight and easy to install, saving time and labor costs during construction. Lastly, these materials are highly flexible and adaptable, making them suitable for various project conditions and allowing for effective reinforcement and stabilization of the canal lining.

- Q: How can geopipes be used in underground stormwater retention systems?

- Geopipes can be used in underground stormwater retention systems to efficiently collect and transport excess water from heavy rainfall events. These specially designed pipes, often made of high-density polyethylene, are perforated to facilitate water infiltration into the surrounding soil while preventing clogging. By directing stormwater into underground retention systems through geopipes, the water can be stored and gradually released, reducing the strain on local drainage systems and minimizing the risk of urban flooding.

Send your message to us

Sodium Bentonite Geosynthetic Clay Liner(GCL)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords