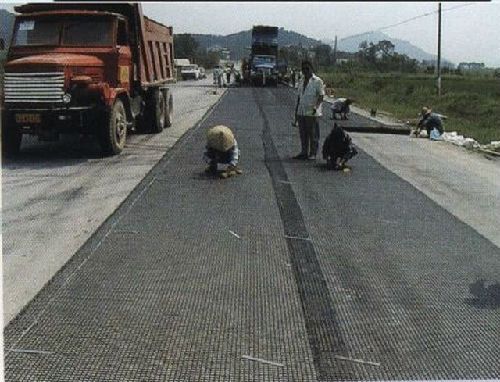

HDPE Biaxial Geogrids for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.HDPE geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.

2.This product is made by HDPE. The products after surface covering own the favorable property of alkali resistance and aging resistance.

3.This product is also used to strengthen the soft land, such as railway, airport,irrigation work, and dyke, etc, and the roadbed.

HDPE Uniaxial geogrid Product Poperties

Specification | 50 | 60 | 80 | 90 | 100 | 110 | 120 | 150 | 160 | 190 | 220 |

Width( m) | 1 or 1.1 or 2.5 or 3 | ||||||||||

Tensile strength≥(kN/m) | 50 | 60 | 80 | 90 | 100 | 110 | 120 | 150 | 160 | 190 | 220 |

Elongation ≤(%) | 11.5 | ||||||||||

Tensile strength at 2% strain≥(kN/m) | 12 | 14 | 21 | 24 | 26 | 29 | 33 | 41 | 47 | 55 | 64 |

Tensile strength at 5% strain≥(kN/m) | 23 | 27 | 40 | 45 | 50 | 55 | 65 | 81 | 93 | 110 | 127 |

- Q: What are the differences between geogrids and geocells in terms of installation?

- Geogrids and geocells differ in terms of installation primarily because of their structural designs. Geogrids are typically rolled out and laid on a prepared surface, followed by anchoring them using stakes or pins. On the other hand, geocells are assembled on-site and filled with soil, aggregate, or other materials to create a stable structure. This process involves connecting individual cells and securing them together, forming a three-dimensional honeycomb-like structure. Therefore, while geogrids require relatively simpler installation techniques, geocells demand more labor and time for assembly.

- Q: Can geogrids be used in reinforcement of rock slopes?

- Yes, geogrids can be used in the reinforcement of rock slopes. Geogrids are commonly used to stabilize and reinforce soil slopes, but they can also be effective in reinforcing rock slopes. By providing additional tensile strength, geogrids can help prevent slope failure and improve the stability and durability of rock slopes.

- Q: How do geogrids improve the stability of cut slopes?

- Geogrids improve the stability of cut slopes by reinforcing the soil and preventing erosion. When placed within the soil, geogrids provide tensile strength and distribute the forces acting on the slope, reducing the risk of slope failure. They also enhance the overall stability by increasing the shear strength of the soil, minimizing displacement and potential sliding. Additionally, geogrids help to control water infiltration, reducing pore pressure and preventing saturation, which can further compromise the stability of cut slopes.

- Q: Can geogrids be used in reinforcement of soil-lime mixtures?

- Yes, geogrids can be used in the reinforcement of soil-lime mixtures. Geogrids are commonly used in civil engineering and construction projects to improve the stability and strength of soil-lime mixtures. They provide additional tensile strength, prevent soil erosion, and enhance the load-bearing capacity of the mixture. By adding geogrids, the performance and durability of soil-lime mixtures can be significantly improved.

- Q: Are geogrids resistant to UV degradation?

- Yes, geogrids are generally resistant to UV degradation. They are designed to withstand prolonged exposure to sunlight without significant degradation or loss of strength.

- Q: What are the differences between geogrids and geosynthetic clay liners?

- Geogrids and geosynthetic clay liners (GCLs) are both types of geosynthetics used in civil engineering, but they differ in terms of composition, function, and application. Geogrids are typically made of high-strength polymer materials, such as polyester or polypropylene, and are designed to provide reinforcement and stabilization to soil or aggregate layers. They have a grid-like structure with open apertures that allow for soil interlocking, enhancing the load-bearing capacity of the soil. Geogrids are commonly used in applications such as retaining walls, road construction, and erosion control. On the other hand, geosynthetic clay liners (GCLs) consist of a layer of natural sodium bentonite clay sandwiched between two geotextile layers. The clay layer acts as a hydraulic barrier, providing excellent seepage control and preventing the migration of liquids or gases. GCLs are often employed in environmental containment systems, such as landfill liners or caps, and in other applications that require effective containment of fluids. In summary, while geogrids primarily focus on reinforcement and stabilization of soil, geosynthetic clay liners specialize in seepage control and containment. Their differing compositions and functions make them suitable for distinct engineering purposes.

- Q: Can geogrids be used in foundation stabilization?

- Yes, geogrids can be used in foundation stabilization. They are commonly used in civil engineering and construction projects to reinforce soil and improve the stability of foundations. Geogrids are typically installed horizontally or vertically within the soil to distribute loads and prevent soil movement, thereby enhancing the overall stability and performance of foundations.

- Q: Bidirectional geogrid 5 meters long side, short side of the 3 meters

- That is 5 meters long, width of 3 meters

- Q: Can geogrids be used in reinforced earth walls?

- Yes, geogrids can be used in reinforced earth walls. Geogrids are commonly used as reinforcement elements in reinforced earth walls to improve stability and increase load-bearing capacity. They provide tensile strength and distribute loads, preventing soil movement and enhancing the overall performance of the structure.

- Q: See details of the application of design code for railway embankment geosynthetics TB10018-2006

- The vertical and horizontal strength fracture elongation is basically on the other side of the 2 point and sometimes the strength of the joint is required!

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

HDPE Biaxial Geogrids for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords