Gutter Aluminum Coil - Custom Size 1000 Series, 3000 Series, 5000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Coil Custom Size 1000 series, 3000 series, 5000 series

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Aluminum Coil Custom Size 1000 series, 3000 series, 5000 series

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Coil Custom Size 1000 series, 3000 series, 5000 series

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

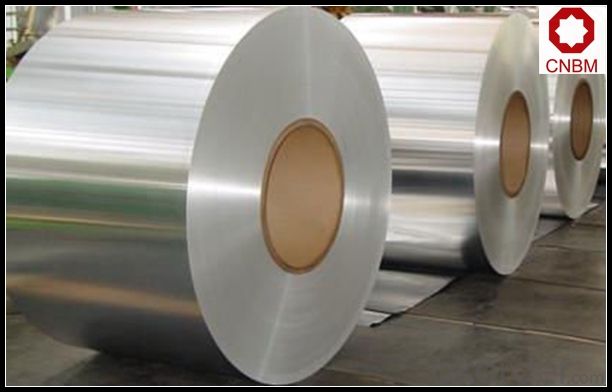

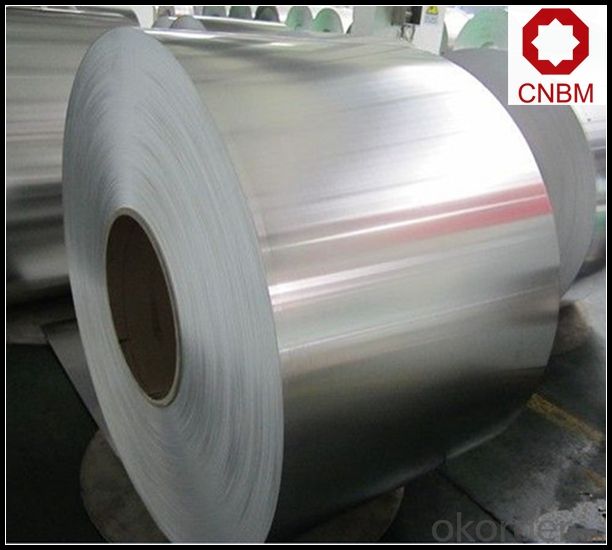

5. Image of Aluminum Coil Custom Size 1000 series, 3000 series, 5000 series

6. Package and shipping of Aluminum Coil Custom Size 1000 series, 3000 series, 5000 series

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to utilize aluminum coils in the construction industry as building materials?

- <p>Yes, aluminum coils can be used for building materials. They are valued for their lightweight, corrosion resistance, and strength. Aluminum coils are commonly used in roofing, siding, window frames, and facades due to their durability and low maintenance requirements. Additionally, they can be easily shaped and recycled, making them an environmentally friendly option in construction.</p>

- Q: How are aluminum coils coated for color matching and aesthetic purposes?

- Aluminum coils are coated for color matching and aesthetic purposes through a process called coil coating. During this process, a layer of paint or coating material is applied to the aluminum coil. The coil is first cleaned and treated to ensure proper adhesion of the coating. Then, a primer is applied to improve corrosion resistance. Finally, a topcoat is added to achieve the desired color and aesthetics. This process ensures that the aluminum coils have a consistent color and finish, making them suitable for various applications such as building facades, automotive parts, and appliances.

- Q: May anyone tell me what's the product when hydrochloric acid reacts with aluminum?HCl + Al → ?

- you may separate the hydrogen by electrolysis. purely take your tube of gas and place the tube face down in salt water. Then get yet another attempt tube and fill it halfway with salt water. The salt interior the water helps the water to grow to be a greater powerful conductor it is by the fact NaCl is an ion. This ionizes the water and helps conduction. Then after installation the attempt tubes, get a batter and connect it to a dazzling and unfavourable plate with the corresponding terminals on the battery. Then turn on the battery. The water ought to separate out of the tube, leaving the hydrogen. the different tube with be crammed with all the water. to answer your 2d question.... The gas that would want again out to be hydrogen. 6HCl + 2Al = 2AlCl3 + 3H2(gas)

- Q: What are the necessary safety measures one should take while using aluminum coils in a kitchen setting?

- <p>When using aluminum coil in a kitchen, safety precautions include: 1) Ensuring proper ventilation to avoid inhaling fumes, as aluminum dust can be harmful. 2) Wearing protective gear such as gloves and goggles to protect your skin and eyes from potential contact with aluminum or sharp edges. 3) Handling the aluminum coil carefully to prevent cuts or injuries. 4) Avoiding contact with acidic or alkaline substances, as aluminum can react with them. 5) Not using aluminum coil near open flames or high heat sources, as it can melt or cause fires. 6) Cleaning up any aluminum dust or debris promptly to prevent slipping hazards. 7) Storing aluminum coils in a dry, cool place away from chemicals and heat sources.</p>

- Q: How much will be burned out if the soaked and oxidized 5182 aluminum coil is melt down and reprocessed?

- Burn out rate is generally between 1% -2.5%, but that varies among plants as their actual situations are different.

- Q: Are there any environmental benefits to using aluminum coils?

- Yes, there are several environmental benefits to using aluminum coils. Firstly, aluminum is a highly recyclable material, meaning that it can be reused multiple times without losing its quality. This reduces the need for extracting and processing new raw materials, saving energy and reducing carbon emissions. Additionally, aluminum coils are more lightweight compared to other materials, reducing transportation fuel consumption and associated greenhouse gas emissions. Moreover, aluminum has a longer lifespan, making it more durable and reducing waste generation. Overall, using aluminum coils contributes to a more sustainable and eco-friendly approach in various industries.

- Q: Can aluminum coils be used in high-altitude environments?

- Indeed, the utilization of aluminum coils is feasible in high-altitude settings. Thanks to its lightweight and resistance to corrosion, aluminum is a fitting material for various purposes, including in high-altitude scenarios. Aluminum coils are often employed in air conditioning systems, heat exchangers, and refrigeration units, all of which can operate efficiently at high altitudes. The high strength-to-weight ratio of aluminum enables it to endure the harsh conditions encountered at high altitudes, encompassing low temperatures, strong winds, and low atmospheric pressure. Moreover, aluminum is non-magnetic, providing an advantage in specific high-altitude applications like aerospace and satellite technologies. Additionally, aluminum exhibits exceptional thermal conductivity, facilitating efficient heat transfer and rendering it perfect for deployment in cooling systems functioning in high-altitude environments. Its resistance to corrosion also ensures durability and the ability to withstand the impact of moisture, which can be prevalent in such settings. All in all, owing to their lightweight nature, resistance to corrosion, thermal conductivity, and strength, aluminum coils serve as a dependable and appropriate choice for utilization in high-altitude environments.

- Q: What are the different surface protection options available for aluminum coils?

- Depending on the specific requirements and applications, there are several options available for surface protection on aluminum coils. 1. Applying a paint coating is a common method of surface protection. This creates a protective layer that helps prevent corrosion, oxidation, and damage from environmental factors. Paint coatings also provide aesthetic appeal and come in various colors and finishes. 2. Anodizing is an electrochemical process that creates a durable and corrosion-resistant oxide layer on the aluminum coil's surface. This method enhances the coil's resistance to wear and tear and provides a decorative appearance. Anodized coatings can be clear or colored, offering design flexibility. 3. Another option is applying a protective film made of plastic or vinyl on the surface of the aluminum coil. This film provides temporary protection during transportation, handling, and installation, guarding against scratches and abrasions before being removed. 4. Powder coating involves the electrostatic application of a dry powder onto the aluminum coil's surface. The powder is then cured under heat, resulting in a durable and resilient protective layer. Powder coatings are known for their excellent resistance to chemicals, UV rays, and physical impacts. 5. Cladding, or laminating, involves bonding a protective layer, such as PVC, onto the aluminum coil's surface. This method enhances resistance against scratches, impact, and weathering. Cladding can also provide additional benefits like thermal insulation and noise reduction. When selecting the most suitable surface protection option for aluminum coils, it is important to consider factors such as the intended use, environmental conditions, desired aesthetics, cost, durability, and application requirements.

- Q: How are aluminum coils tested for quality control?

- Aluminum coils undergo several tests during quality control to ensure their reliability and performance. One of the primary tests is the dimensional inspection, where the physical dimensions of the coils are measured and compared against the specifications provided by the manufacturer. This helps to identify any discrepancies in length, width, thickness, or diameter. Another crucial test is the visual inspection, where the coils are thoroughly examined for any surface defects such as scratches, dents, or discoloration. This visual examination is essential to ensure that the coils meet the required aesthetic standards. To evaluate the mechanical properties, various mechanical tests are conducted. Tensile strength tests are performed to measure the resistance of the aluminum coils to breaking under tension. This test helps in determining the durability and strength of the coils. Additionally, hardness tests are carried out to assess the coil's resistance to indentation or deformation. The hardness values are compared against the predetermined standards to verify if the coils meet the necessary criteria. Further tests include corrosion resistance testing, where the coils are exposed to harsh environments or corrosive substances to assess their ability to withstand corrosion over time. This test is crucial as aluminum is often used in applications where it may come into contact with corrosive elements. Electrical conductivity tests are conducted to ensure the proper functioning of the coils in electrical applications. The conductivity is measured and compared with the required specifications to guarantee that the coils possess the desired electrical characteristics. In addition to these tests, other factors like chemical composition analysis, surface roughness evaluation, and coating adhesion tests may also be performed depending on the specific requirements of the aluminum coils. Overall, through these comprehensive quality control tests, manufacturers can ensure that aluminum coils meet the necessary standards, guaranteeing their quality, performance, and reliability in various applications.

- Q: How are aluminum coils processed and fabricated?

- Aluminum coils go through a series of steps to transform them into desired forms for various uses. Typically, the process includes the following steps: 1. Manufacturing Coils: Aluminum coils are initially made by melting aluminum ingots and casting them into large, flat coils. These coils are then rolled through rolling mills to achieve the desired thickness and shape. 2. Cleaning Coils: After rolling, the coils undergo a cleaning process to eliminate any dirt, oil, or impurities that may have accumulated during manufacturing. This is usually done using chemical cleaning agents or mechanical scrubbing techniques. 3. Annealing Coils: Annealing is a heat treatment process where the coils are heated to a specific temperature and slowly cooled. This process helps to relieve internal stresses, enhance the coil's mechanical properties, and improve its formability. 4. Slitting Coils: In this step, the large coils are cut into narrower strips or sheets of desired widths. A slitting machine is used to accomplish this, allowing for better material utilization and ensuring the coils meet the required dimensions for further processing. 5. Treating Coil Surfaces: Aluminum coils often undergo surface treatments to enhance their appearance, improve corrosion resistance, or provide additional protection. Common treatments include anodizing, painting, or applying a protective coating. 6. Fabricating Coils: Once cleaned, annealed, and treated, the coils can be further processed into various shapes and forms. Common fabrication techniques include stamping, bending, deep drawing, roll forming, welding, and machining. These processes allow for the transformation of aluminum coils into components such as sheets, plates, tubes, profiles, or intricate designs. 7. Controlling Quality: Throughout the entire processing and fabrication stages, strict quality control measures are implemented to ensure that the final products meet the required specifications and standards. Regular inspections and tests for mechanical properties, dimensional accuracy, surface quality, and other relevant parameters are conducted. In summary, the processing and fabrication of aluminum coils involve a combination of metallurgical, mechanical, and chemical processes. These processes aim to enhance the properties of aluminum, improve its formability, and create a wide range of products for various industries such as automotive, construction, aerospace, and packaging.

Send your message to us

Gutter Aluminum Coil - Custom Size 1000 Series, 3000 Series, 5000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords