Customized Color Aluminum Coated Coils for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

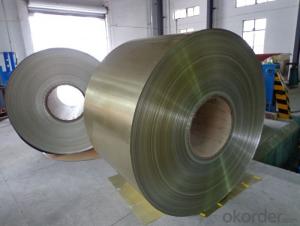

1. Structure of Plain Aluminium Coils for Different Usages Our aluminum Coils are widely used in solar energy curtain wall. It integrates a photo-voltaic system. Photovoltaic panels are usually installed on the glass of curtain wall to generate electricity from solar energy. Plain Aluminium Coils for Different Usages can meet the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209. 2.Main Features of Plain Aluminium Coils for Different Usages •High intensity •Easy to be processed and shaped •Weather resistance •Anti-pollution & environment protection 3. Plain Aluminium Coils for Different Usages Images 4.Specification of Plain Aluminium Coils for Different Usages Alloy: AA1×××; AA3×××; AA5×××; AA8××× Temper: H14; H16; H18; H22; H24; H26; H32; O; F Thickness: 0.2mm-100mm Width: 30mm-1700mm Standard: GB/T 3880-2006 5.FAQ A.What about inspections to guarantee quality? For each order for Aluminum Coils, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods. With requirement of customers, we also can arrange the third party inspection. B.What about delivery? We will put order for Aluminum Coils in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity. C.What is the MOQ? 5 tons for each size. D. Where have you exported aluminium Coils? We have exported aluminum Coils to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What are the proper storage methods for keeping aluminum coil in good condition?

- <p>To store aluminum coil properly, ensure a clean, dry, and well-ventilated environment. Keep the coil away from moisture and direct sunlight to prevent oxidation and discoloration. Store coils horizontally on wooden pallets or racks to avoid deformation. Maintain a consistent temperature and avoid extreme fluctuations. Use protective coverings or wrapping to shield the coil from dust and contaminants. Regularly inspect the coils for any signs of damage or corrosion and address any issues promptly.</p>

- Q: Explain the differences between aluminum coil and aluminum sheet in a few sentences.

- <p>Aluminum coil and aluminum sheet are both flat aluminum products but differ in form and usage. Aluminum coil is a long, continuous roll of aluminum that can be easily unrolled and cut to length, making it ideal for manufacturing processes where the material needs to be fed through machines. It is commonly used in industries such as construction, packaging, and automotive for applications like roofing, siding, and food packaging. Aluminum sheet, on the other hand, comes in flat, rectangular pieces with specific dimensions and is typically thicker than coil. It is used in applications where a solid, non-continuous piece is required, such as in signage, furniture, and decorative elements. The thickness and surface finish can also vary between coils and sheets, with sheets often being available in a wider range of finishes and thicknesses.</p>

- Q: How are aluminum coils protected against galvanic corrosion?

- To protect aluminum coils from galvanic corrosion, a combination of surface treatments and protective coatings is employed. An effective method involves applying anodization, which entails treating the aluminum with an acid solution through electrolysis. This process forms a protective oxide layer on the surface, acting as a barrier against direct contact with other metals that could cause galvanic corrosion. Alternatively, a protective coating such as a polymer or paint can be used on the aluminum coils. These coatings create a physical barrier, shielding the metal from corrosive elements in the environment. Careful consideration is given to selecting coatings that adhere well to the aluminum surface and exhibit excellent resistance to corrosion. Aside from surface treatments and coatings, proper design and material selection are crucial in safeguarding aluminum coils against galvanic corrosion. Avoiding direct contact between dissimilar metals and opting for compatible materials helps minimize the risk of corrosion. Isolation materials, such as gaskets or insulating tapes, can be utilized to separate the aluminum coil from other metals in contact. Regular maintenance and cleaning also contribute to protection against galvanic corrosion. It is essential to regularly remove accumulated dirt, debris, and corrosive substances from the aluminum coils to prevent the formation of localized corrosion cells. In conclusion, a combination of surface treatments, protective coatings, proper design, and regular maintenance is vital in preserving the longevity and performance of aluminum coils in various applications.

- Q: How do aluminum coils contribute to improved indoor air quality?

- Various ways are improved by aluminum coils in enhancing indoor air quality. Primarily, these coils are commonly used in air conditioning and HVAC systems, which are designed for circulating and filtering the air inside buildings. The cooling and dehumidifying of the air, reducing moisture content that can encourage the growth of mold and mildew, is assisted by the aluminum coils in these systems. By controlling humidity levels, allergens and pollutants that thrive in damp environments are prevented from developing, thus enhancing indoor air quality. In addition, aluminum coils function as highly efficient heat exchangers, facilitating effective heat transfer between the air and the cooling or heating system. This efficiency enables HVAC systems to maintain a consistent temperature throughout the building, resulting in reduced energy consumption. Through the use of less energy, these systems emit fewer harmful greenhouse gases, ultimately contributing to lower levels of outdoor air pollution and improving overall air quality. Furthermore, the durability and resistance to corrosion of aluminum coils are essential for maintaining a clean and healthy indoor environment. The corrosion-resistant properties of aluminum coils ensure that no metallic particles or rust contaminate the circulated air. Consequently, occupants are less likely to inhale harmful particles that can cause respiratory issues and other health problems. Moreover, aluminum coils are lightweight and often come with a protective coating, making them easier to clean and maintain. Regular cleaning of coils prevents the accumulation of dust, dirt, and other pollutants over time. By keeping the coils clean, airflow is optimized, ensuring that the circulated air is free from contaminants and allergens, thus promoting improved indoor air quality. In summary, aluminum coils contribute to improved indoor air quality by reducing humidity levels, preventing the growth of mold and mildew, enhancing energy efficiency, minimizing the emission of greenhouse gases, and maintaining a clean and contaminant-free air circulation system. These coils are an essential component of HVAC systems that play a vital role in creating a healthier and more comfortable indoor environment for occupants.

- Q: How is an aluminum coil made?

- An aluminum coil is made through a process called aluminum coil rolling, which involves several stages of manufacturing. The process begins with casting, where molten aluminum is poured into large molds to form large ingots or billets. These ingots are then heated to a specific temperature to improve their malleability. Once heated, the ingots are hot-rolled into thin strips using heavy machinery known as hot rolling mills. During this process, the ingots are passed through a series of rollers that gradually reduce their thickness while increasing their length. This continuous hot rolling ensures a uniform thickness and smooth surface finish. After hot rolling, the aluminum strips are cooled and then subjected to further processing. They are often subjected to cold rolling, which involves passing the strips through cold rolling mills. Cold rolling further reduces the thickness of the aluminum strips, creating the desired gauge or thickness required for the final product. To improve the mechanical properties and surface finish of the aluminum, the cold-rolled coils may undergo additional processes such as annealing, tempering, or surface treatment. Annealing involves heating the coils to a specific temperature and then slowly cooling them to relieve internal stresses and improve their ductility. Tempering is a similar process that involves reheating the coils to a lower temperature than annealing. Once the desired properties are achieved, the aluminum coils are typically trimmed, cut, and packaged into coils or sheets, ready for distribution or further fabrication. These coils can be used in various industries, such as construction, automotive, aerospace, and packaging, where their lightweight, corrosion resistance, and excellent thermal conductivity make them highly sought after materials.

- Q: Can aluminum coils be used for automotive heat shields?

- Yes, aluminum coils can be used for automotive heat shields. Aluminum is a lightweight and durable material that has excellent heat resistance properties, making it suitable for use in automotive heat shields. Its ability to dissipate heat efficiently helps protect sensitive components from excessive heat, ensuring optimal performance and durability in vehicles.

- Q: I know that Aluminum is a metal, and it's corrosive, but I've been wondering about how Aluminum Foil is created. Is it the same as the metal? Just pounded down? or is it a mixture of different elements?

- It is made by rolling an aluminum block thinner and thinner. Metal foil, such as tin foil had been around for years. The first plant designed for rolling aluminum foil was opened in 1910. NASA was not in existence then. It appears the inventor was: Hans Christian Oersted Year Invented: 1825 P.S. Aluminum is not corrosive. corrosive means it corrodes other things (as acid would). It does corrode. It is also the most reactive metal. It is oxidized immediately upon exposure to air - why it is difficult to solder. The aluminum oxide is not whetted by solder. Aluminum oxide is a ceramic, called Alumina. Anodized aluminum has has a thick layer of aluminum oxide formed on its surface

- Q: What is the flexural strength of aluminum coils?

- The flexural strength of aluminum coils varies depending on the specific grade and thickness of the aluminum used. Generally, aluminum coils have good flexural strength due to the inherent properties of aluminum, which is known for its high strength-to-weight ratio.

- Q: How are aluminum coils annealed?

- Aluminum coils are typically annealed through a process known as heat treatment. This involves heating the coils to a specific temperature and then slowly cooling them down. The purpose of annealing is to soften the aluminum and improve its ductility, making it easier to work with. The first step in annealing aluminum coils is to clean them thoroughly to remove any contaminants. The coils are then placed in a furnace, which is heated to the desired temperature. The temperature and duration of the annealing process depend on the specific grade and thickness of the aluminum being treated. Once the coils reach the desired temperature, they are held at that temperature for a predetermined amount of time. This allows for the internal structure of the aluminum to become more uniform and relieves any internal stresses that may have developed during the manufacturing process. After the annealing process is complete, the coils are slowly cooled down in the furnace. This slow cooling is important to prevent the formation of any new internal stresses. Once the coils have cooled to room temperature, they are ready for further processing or use. In some cases, a process known as quenching may be used after annealing. Quenching involves rapidly cooling the aluminum by immersing it in a quenching medium, such as water or oil. This can help to further improve the mechanical properties of the aluminum, such as its strength and hardness. Overall, the annealing process for aluminum coils is a carefully controlled heat treatment that aims to improve the metal's properties and make it more suitable for various applications.

- Q: Are aluminum coils suitable for decorative purposes?

- <p>Yes, aluminum coils can be used for decoration. They are lightweight, durable, and corrosion-resistant, making them ideal for various decorative applications. Aluminum coils can be shaped and colored to suit different design needs, often used in architectural features, interior design elements, and even in art installations. Their versatility and aesthetic appeal make them a popular choice for both commercial and residential decoration.</p>

Send your message to us

Customized Color Aluminum Coated Coils for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords