Fiberglass Mat Tissue Glass Wool Home Insulation Product with CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property. At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

g):ventilation property

Glass wool, with multiaperture structure and special prescription, make its better performance in ventilation property. It contribute to moisture diffusion indoor and wall and greatly decrease the possibility of leaf mold growth. Thus it can help to increase service life of building and indoor comfort level.

h): Hydrophobicity

Hydrophobicity glass wool in panel wall bears 99% Hydrophobicity rate. It can easily get dry naturally, which ensure its long-term heat preservation perporty.

i): Light in weight

Glass wool bears good heat preservation and soundproofing property. It’s low density product can meet energy saving requirement. Thus it helps to decrease the weight of building and makes the construction more expedite.

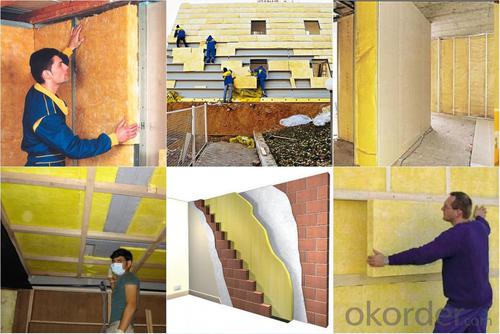

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can fiberglass mat tissue be used for flooring insulation?

- No, fiberglass mat tissue is not typically used for flooring insulation. Fiberglass mat tissue is a lightweight material often used in the construction industry for applications such as reinforcing plaster and concrete, as well as for insulation in walls and ceilings. However, when it comes to flooring insulation, other materials such as foam boards or batt insulation are more commonly used. These materials provide better thermal and sound insulation properties specifically designed for flooring applications. Additionally, foam boards and batt insulation are easier to install and are better suited to withstand the pressures and demands of foot traffic on the flooring.

- Q: What are the different quality standards for fiberglass mat tissue?

- Various quality standards are utilized to evaluate the quality of fiberglass mat tissue, ensuring its suitability for intended applications and meeting performance requirements. The ASTM D2178 standard is widely used to assess the quality of fiberglass mat tissue. This standard outlines the specifications for base materials used in the production of asphalt and coal tar roofing products. It covers physical properties such as weight, thickness, tensile strength, tear resistance, and permeability. Another recognized standard is ISO 3376, which provides guidelines for determining the tensile properties of nonmetallic materials, including fiberglass mat tissue. It defines test methods for parameters like tensile strength, elongation at break, and modulus of elasticity. In Europe, the EN 1871 standard is commonly used for assessing the quality of fiberglass mat tissue. This standard specifies the requirements for reinforced bitumen sheets used in roofing applications. It covers physical properties, dimensional stability, resistance to heat, and resistance to aging. Furthermore, there are industry-specific quality standards that may apply to fiberglass mat tissue used in particular applications. For instance, the ASTM C1666 standard specifically addresses fiberglass reinforced cementitious panels and sets requirements for the materials used in their production. Overall, these various quality standards for fiberglass mat tissue ensure that it meets specific performance criteria and can be effectively utilized in applications such as roofing, construction, and insulation. They establish a framework for manufacturers, suppliers, and customers to assess and compare the quality of different products in the market.

- Q: Can fiberglass mat tissue be used for making lightweight ceilings?

- Yes, fiberglass mat tissue can be used for making lightweight ceilings. Fiberglass mat tissue is a thin and lightweight material made from fiberglass strands that are bonded together with a binder. It is commonly used in construction and building applications due to its excellent strength-to-weight ratio. When used for making lightweight ceilings, fiberglass mat tissue can provide several advantages. Firstly, it is lightweight, which makes it easier to handle and install. This can save time and effort during construction or renovation projects. Additionally, fiberglass mat tissue is also known for its high tensile strength and durability, making it a suitable choice for ceilings that need to withstand various loads and stresses. Furthermore, fiberglass mat tissue has good thermal insulation properties, which can help in maintaining a comfortable indoor environment. It can also offer sound insulation benefits, reducing noise transmission between different spaces or floors. Moreover, fiberglass mat tissue is resistant to moisture, mold, and mildew, which makes it suitable for areas with high humidity or moisture concerns such as bathrooms or kitchens. It is also non-combustible, providing an added level of fire resistance to the ceiling structure. In conclusion, fiberglass mat tissue can indeed be used for making lightweight ceilings. Its lightweight nature, strength, durability, thermal and sound insulation properties, as well as resistance to moisture and fire, make it a suitable choice for various ceiling applications.

- Q: Does fiberglass mat tissue provide any sound insulation?

- Yes, fiberglass mat tissue does provide sound insulation. It is a common material used in various industries, including construction and automotive, to absorb and reduce sound transmission. The fibrous structure of the material helps to trap and absorb sound waves, preventing them from passing through walls or other surfaces. Fiberglass mat tissue is often used as an acoustic insulation material in walls, floors, and ceilings to create a more comfortable and noise-free environment.

- Q: What are the different types of fiberglass mat tissue available?

- There are several different types of fiberglass mat tissues available, each with its own unique characteristics and applications. Some of the most common types include: 1. Chopped Strand Mat (CSM): This is the most basic and widely used type of fiberglass mat tissue. It consists of randomly oriented chopped strands of fiberglass held together with a binder. CSM is typically used in applications where strength and resilience are important, such as boat building and automotive parts manufacturing. 2. Continuous Filament Mat (CFM): Unlike CSM, CFM is made from continuous strands of fiberglass that are woven into a mat. This type of fiberglass mat tissue offers excellent tensile strength and dimensional stability, making it ideal for applications that require high strength and stiffness, such as aerospace components and wind turbine blades. 3. Surface Veil Mat: Surface veil mat is a very thin and lightweight type of fiberglass mat tissue that is used primarily for surface finishing and reinforcement. It is typically applied as a final layer in composite laminates to improve the surface smoothness and water resistance. 4. Stitched Mat: Stitched mat is made by interweaving continuous strands of fiberglass with a stitching thread. This construction provides increased strength and improved drapability, making it easier to conform to complex shapes. Stitched mat is commonly used in applications that require a combination of strength and flexibility, such as in the production of pipes and tanks. 5. Binderless Mat: Binderless mat is a specialty type of fiberglass mat tissue that does not contain any binders or resins. Instead, the fibers are mechanically bonded together using a needling process. This makes binderless mat highly resistant to chemical attack and suitable for use in corrosive environments, such as chemical storage tanks and pipes. These are just a few examples of the different types of fiberglass mat tissues available. The choice of which type to use depends on the specific requirements of the application, including strength, flexibility, surface finish, and resistance to various environmental factors.

- Q: Does fiberglass mat tissue provide any mold resistance?

- While fiberglass mat tissue alone does not possess natural mold resistance, its combination with other mold-resistant materials and proper construction techniques can aid in preventing mold. The fiberglass mat tissue itself may not resist mold growth, but it can be employed as a strengthening layer in mold-resistant building materials like mold-resistant drywall or sheathing. These materials are specifically engineered to hinder the growth of mold and mildew by incorporating additives or coatings. It is also crucial to guarantee the correct installation and upkeep of these materials to minimize moisture accumulation and establish an unfavorable setting for mold to thrive.

- Q: Can fiberglass mat tissue be used for electrical enclosures?

- Typically, fiberglass mat tissue is not employed in the construction of electrical enclosures. These enclosures are specifically designed to shield electrical equipment against external elements including dust, moisture, and physical harm. Usually, materials with excellent insulation and high mechanical strength, such as sheet metal, plastic, or fiberglass reinforced plastic (FRP), are used for their manufacture. Although fiberglass mat tissue can offer certain levels of mechanical strength and insulation, it is not commonly utilized as the main material for electrical enclosures due to its restricted durability and lower resistance to moisture and impact.

- Q: How is fiberglass mat tissue manufactured?

- Fiberglass mat tissue is manufactured by first combining glass fibers with a binder material, usually a water-based emulsion. This mixture is then spread onto a conveyor belt or drum and passed through an oven to dry and cure the binder. The resulting mat is then rolled or cut into the desired dimensions and can be further processed or used as a reinforcement material in various industries such as construction, automotive, and aerospace.

- Q: How does fiberglass mat tissue enhance the strength of composite materials?

- The enhancement of composite material strength is greatly influenced by fiberglass mat tissue. Made up of thin fiberglass strands woven together, the tissue possesses a distinctive structure, with the strands randomly oriented and bonded by a resin binder. This unique structure offers several advantages to composite materials. Firstly, the random orientation of the fiberglass strands within the tissue aids in the even distribution of stress and load across the composite material. Consequently, when a force is exerted on the composite, the tissue prevents localized stress concentrations that could result in cracks or failure. By distributing stress, the fiberglass mat tissue enhances the overall strength and durability of the composite material. Secondly, the resin binder utilized in the fiberglass mat tissue serves as both a reinforcement and bonding agent. During the manufacturing process of the composite material, the resin binder infiltrates the fibers of the tissue, creating a robust and cohesive structure. This not only enhances the overall strength of the composite material but also improves its resistance to impact and fatigue. Moreover, the presence of fiberglass strands within the tissue augments the stiffness of the composite material. When combined with the resin binder, these strands establish a rigid framework that enhances the structural integrity of the composite. This increased stiffness renders the material more resistant to deformation and improves its load-bearing capabilities. Additionally, fiberglass mat tissue offers thermal and electrical insulation properties to composite materials. The fiberglass strands act as a barrier, minimizing heat transfer and preventing electrical conductivity. Consequently, the composite material becomes suitable for applications that require insulation, such as in electrical enclosures or thermal insulation panels. In conclusion, fiberglass mat tissue plays a critical role in enhancing the strength of composite materials by distributing stress, reinforcing the structure, increasing stiffness, and providing additional insulation properties. With its random orientation, resin binder, and unique characteristics, it is an indispensable component in the production of high-performance composites utilized across various industries, including aerospace, automotive, construction, and marine.

- Q: Can fiberglass mat tissue be used for composite panel manufacturing?

- Yes, fiberglass mat tissue can be used for composite panel manufacturing. Fiberglass mat tissue is a thin and lightweight material that is typically made from randomly oriented fiberglass strands bonded together with a binder. It is commonly used as a reinforcement material in composite manufacturing processes. When used in composite panel manufacturing, fiberglass mat tissue is typically combined with other materials such as resin and a core material to create a strong and durable panel. The mat tissue provides reinforcement and strength to the panel, helping to distribute loads and prevent cracking or delamination. Fiberglass mat tissue is known for its excellent tensile strength, dimensional stability, and resistance to chemicals, making it well-suited for use in composite panel manufacturing. It can be used in a variety of applications, including construction, transportation, marine, and aerospace industries. Overall, fiberglass mat tissue is a versatile and effective material that can be successfully used in the manufacturing of composite panels. Its properties and characteristics make it a reliable choice for creating strong and durable panels for various applications.

Send your message to us

Fiberglass Mat Tissue Glass Wool Home Insulation Product with CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords