Fiberglass Mat Tissue Glass Wool Blanket Waterproof Thermal Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

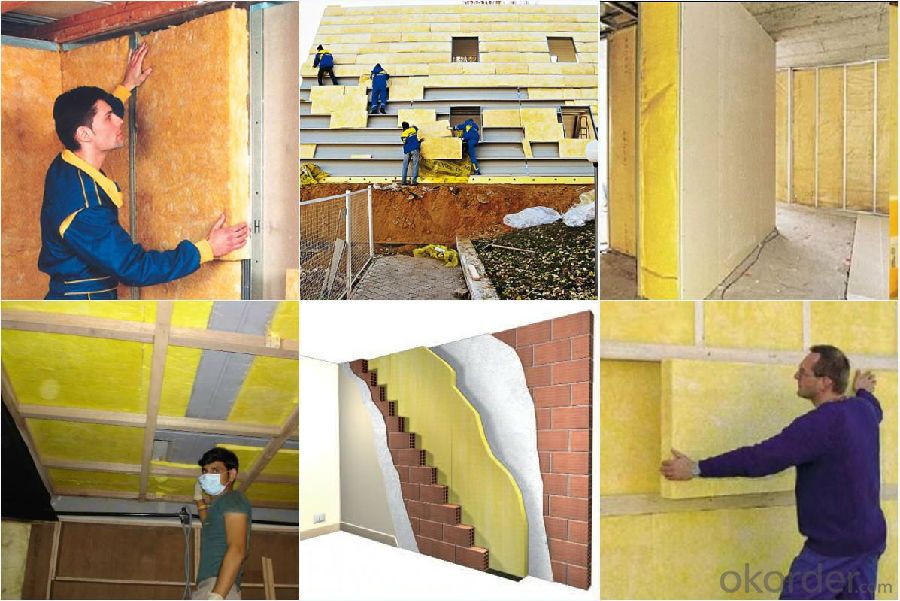

It is widely used for heat insulation and sound absorption in industrial workshops, Prefab houses, Portable cabins, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc..

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property. Glass wool blanket, glass wool board, glass wool pipe, which made from glass wool, largely use in construction, chemical, electronic, electricity, metallurgy, energy industry and community with good performance in heat preservation, heat insulation, sound absorption.

2.Main features of Glass Wool Blanket:

1) Heat insulation and heat preservation, sound adsorption and noise reduction

2) Low slag indusion content, thin and long inner fiber

3) Thermal stability, stable and high efficiency for a long time

4) High temperature heat-stability, durability, high temperature shrinkage resistance

5) Damp proof property, with the hydrophobicity are not less than 98%

6) Excellent fire proof performance, European standard non-flammable class A material

7) Non-poison, not contain rock wool and doesn't grow the mould etc.

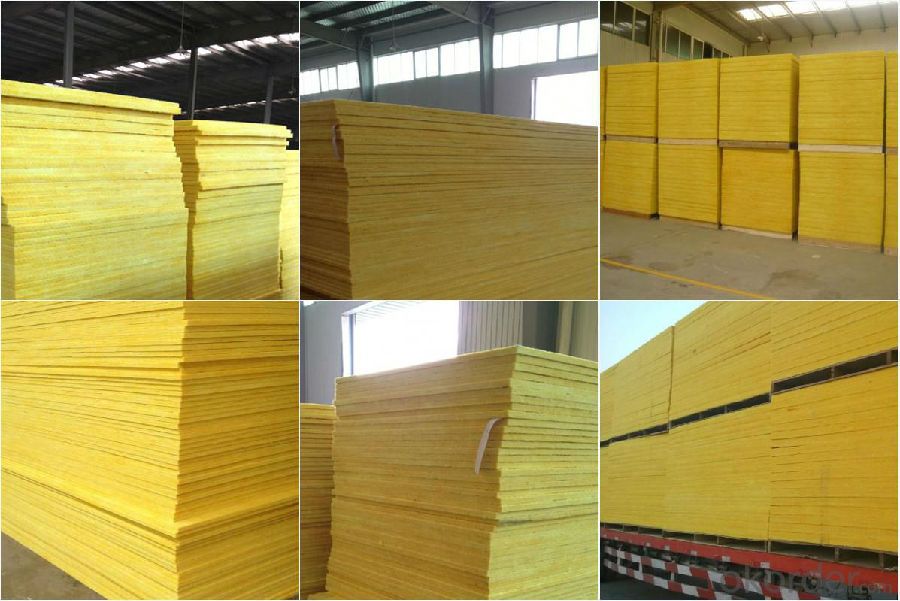

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is fiberglass mat tissue suitable for outdoor applications?

- Yes, fiberglass mat tissue is suitable for outdoor applications. Fiberglass mat tissue is made from woven fiberglass strands that are held together with a binder. This material is highly resistant to water, weather, and UV radiation, making it ideal for use in outdoor environments. It can be used in various outdoor applications such as roofing, insulation, and construction. The waterproof and weatherproof properties of fiberglass mat tissue ensure its durability and longevity when exposed to the elements. Additionally, it is lightweight and easy to handle, making it a versatile choice for outdoor projects.

- Q: How is fiberglass mat tissue used in the production of sports equipment?

- The unique properties and advantages of fiberglass mat tissue make it widely used in the production of sports equipment. This material, made from fine glass fibers bonded together with a binder, is a non-woven fabric with a smooth texture. Despite being lightweight, it is strong and durable. In the manufacturing of sports equipment, fiberglass mat tissue is commonly used as a reinforcing layer. Its purpose is to enhance the strength and rigidity of the final product, making it more resistant to impact and stress. This is particularly important in sports equipment where durability and performance are crucial, such as surfboards, skateboards, snowboards, and tennis rackets. For instance, in the construction of a surfboard, fiberglass mat tissue is typically layered over a foam core and then impregnated with epoxy resin. This combination creates a structure that can withstand the forces exerted by the waves while remaining lightweight. Similarly, in snowboards and skateboards, fiberglass mat tissue is applied to the wooden core to provide additional strength and stiffness, which improves control and responsiveness. Furthermore, fiberglass mat tissue is also utilized in the production of protective gear like helmets and shin guards. By incorporating this material into the manufacturing process, these items can become more impact resistant and capable of absorbing shocks. This is particularly important in high-risk sports, as the fiberglass mat tissue acts as a protective layer, dispersing and diminishing the force of impacts. To summarize, fiberglass mat tissue is vital in the production of sports equipment as it reinforces structures, enhances strength and durability, and improves performance. Its lightweight nature and superior mechanical properties make it an ideal choice for various sporting applications, ensuring athletes can rely on their equipment to perform well while minimizing the risk of injury.

- Q: How is fiberglass mat tissue used in the production of chemical reactors?

- Fiberglass mat tissue is commonly used in the production of chemical reactors due to its exceptional properties. The mat tissue is made up of randomly oriented glass fibers, which are then bonded together with a binder material. This composition makes it an ideal material for the construction of chemical reactors. One of the primary uses of fiberglass mat tissue in chemical reactors is as a reinforcement material. The tissue is typically applied to the inner surfaces of the reactor to enhance its structural integrity. The combination of glass fibers and binder creates a strong and durable layer that can withstand the harsh conditions inside the reactor, such as high temperatures and corrosive chemicals. Additionally, fiberglass mat tissue also acts as a barrier against chemical attack. Chemical reactors often contain aggressive substances that can degrade traditional materials. However, the chemical resistance of fiberglass mat tissue makes it highly suitable for such environments. It effectively prevents the corrosive chemicals from penetrating the reactor walls, ensuring the longevity and reliability of the equipment. Furthermore, fiberglass mat tissue can also provide thermal insulation properties to chemical reactors. This is particularly important in processes where temperature control is crucial. The insulation properties of the tissue help maintain the desired temperature inside the reactor, preventing heat loss or gain, which could affect the efficiency and consistency of the chemical reactions. In summary, fiberglass mat tissue plays a vital role in the production of chemical reactors by reinforcing the structure, providing chemical resistance, and offering thermal insulation. Its unique properties make it an excellent choice for ensuring the durability, safety, and optimal performance of chemical reactors in various industrial applications.

- Q: What are the typical mechanical properties of fiberglass mat tissue?

- The typical mechanical properties of fiberglass mat tissue include high tensile strength, stiffness, and dimensional stability. Fiberglass mat tissue is known for its excellent resistance to breakage and deformation under stress, making it suitable for applications that require durability and structural integrity. It also exhibits good impact resistance, allowing it to withstand external forces without significant damage. Additionally, fiberglass mat tissue has a low coefficient of thermal expansion, meaning it is less prone to expanding or contracting with temperature changes, resulting in improved dimensional stability. These properties make fiberglass mat tissue a popular choice in various industries, such as construction, automotive, and aerospace, where strength and reliability are crucial factors.

- Q: What is the shelf life of fiberglass mat tissue?

- The shelf life of fiberglass mat tissue can vary depending on several factors such as storage conditions, packaging, and the specific manufacturer's recommendations. Generally, fiberglass mat tissue can have a shelf life of around one to two years if stored in a cool, dry place and unopened. However, it is important to note that over time, the material may degrade or lose its physical properties, which can affect its performance and suitability for use. Therefore, it is advisable to always check the manufacturer's guidelines or consult with them directly for the most accurate information regarding the shelf life of a particular fiberglass mat tissue product.

- Q: Glass fiber cotton or ceramic fiber paper insulation?

- Glass fiber cotton bar, there are more air inside, the effect may be better

- Q: Can fiberglass mat tissue be used for reinforcement in composites?

- Yes, fiberglass mat tissue can be used for reinforcement in composites. Fiberglass mat tissue is a non-woven material made up of randomly oriented glass fibers. It is commonly used as a reinforcement material in composite manufacturing processes. The mat tissue is often combined with resin to create a strong and durable composite material. The random orientation of the fibers provides multidirectional strength and reinforcement to the composite structure. Additionally, the mat tissue can be easily layered and molded into complex shapes, making it a versatile choice for various applications in industries such as automotive, aerospace, construction, and marine. Overall, fiberglass mat tissue is an effective and widely used reinforcement material in composites.

- Q: What is the chemical resistance of fiberglass mat tissue?

- Fiberglass mat tissue has excellent chemical resistance due to its composition, which includes a high percentage of glass fibers. These fibers provide a barrier against various chemicals, making the fiberglass mat tissue highly resistant to corrosion and degradation when exposed to acids, alkalis, solvents, and other harsh chemicals.

- Q: Can fiberglass mat tissue be used for making lightweight stairs?

- Yes, fiberglass mat tissue can be used for making lightweight stairs. Fiberglass mat tissue is a thin, lightweight material that is made from randomly oriented glass fibers bonded together with a resin. It is commonly used in construction and manufacturing industries due to its strength, durability, and lightweight properties. When used in the production of stairs, fiberglass mat tissue can be layered and molded to create a lightweight yet strong structure. This material has excellent tensile strength and dimensional stability, making it suitable for supporting the weight of individuals using the stairs. Furthermore, fiberglass mat tissue is resistant to moisture, chemicals, and UV rays, making it ideal for outdoor or high-moisture environments. It is also fire-resistant, which adds to the safety aspect of using it for stairs. Overall, fiberglass mat tissue is an excellent choice for making lightweight stairs as it combines strength, durability, and resistance to various environmental factors.

- Q: Can fiberglass mat tissue be used for repairing fiberglass RVs?

- Yes, fiberglass mat tissue can be used for repairing fiberglass RVs. Fiberglass mat tissue is a lightweight, flexible material that is commonly used for reinforcing and repairing fiberglass structures. It is designed to be easily molded and shaped to fit the contours of the damaged area, making it ideal for repairing RVs, which often have curved surfaces. To repair a fiberglass RV using fiberglass mat tissue, the damaged area needs to be cleaned and prepared by removing any loose or damaged fiberglass. The mat tissue is then cut to the appropriate size and shape to cover the damaged area. A suitable fiberglass resin or adhesive is applied to both the damaged area and the backside of the mat tissue. The tissue is then carefully placed over the damaged area and pressed down to ensure proper adhesion. Once the repair is complete, the fiberglass resin or adhesive is allowed to cure according to the manufacturer's instructions. After curing, the repaired area can be sanded, primed, and painted to match the rest of the RV's exterior. It is important to note that fiberglass mat tissue is typically used for smaller repairs and cosmetic damage. For larger structural repairs, it may be necessary to use additional reinforcement materials such as fiberglass cloth or woven roving. It is recommended to consult with a professional or refer to specific repair guides for detailed instructions on repairing fiberglass RVs.

Send your message to us

Fiberglass Mat Tissue Glass Wool Blanket Waterproof Thermal Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords