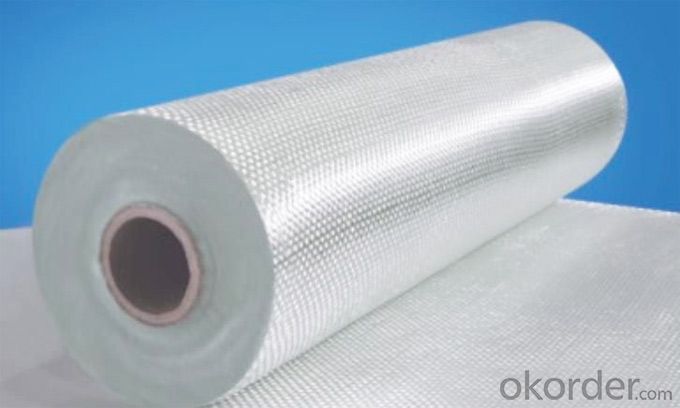

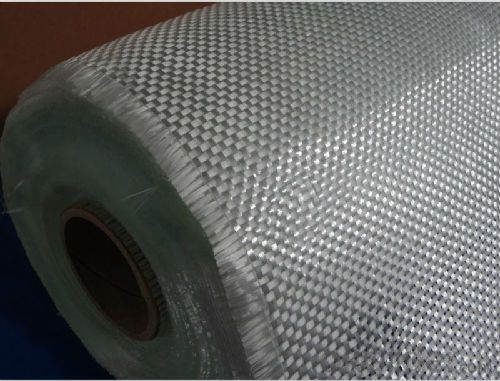

Fiberglass Glass Fiber Woven Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER MONTH kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Woven roving is a bidirectional fabric made by roving in plian weave pattern. The construction impants to the fabric an excellent dimensional stability during handling. Woven roving is a high-performance reinforcement and widely used in hand and machine procuction, such as boats,vessels,planes and automotive parts,furniture and sports facilities,and other fields

| Item | Warp Density Ends/cm | Weft Density Ends/cm | Weight G/m2 |

| EWR270 | 46 | 41 | 270±14 |

| EWR300 | 32 | 18 | 300±15 |

| EWR360 | 32 | 18 | 360±18 |

| EWR400 | 23 | 22 | 405±20 |

| EWR500A | 22 | 20 | 504±25 |

| EWR500 | 20 | 16 | 520±26 |

| EWR580 | 26 | 22 | 580±29 |

| EWR600B | 20 | 16 | 620±31 |

| EWR600C | 28 | 20 | 600±30 |

| EWR600D | 20 | 20 | 610±31 |

| EWR800B | 20*2 | 16*2 | 850±43 |

| EWR800C | 28 | 20 | 840±42 |

| EWR800D | 20*2 | 12*2 | 847±42 |

| EWR800 | 20*2 | 15*2 | 840±42 |

Applications

1.Elementary material of FRP with anticorrosion and insulation.

2.Fireproofing and waterproof use.

3.Mainly applied in the production of boats, fiberglass pipes, containers and sports equipment

4.Applied in the automobile parts, furniture, fiberglass reinforced plastic product, etc.

Features

1.Warp and weft rovings aligned in a parallel, flat manner and uniform tension

2.Densely aligned fibers, providing high dimensional stability and easy handing

3.Good moldabllity, fast and complete resin wet-out, enabling high productivity

4.Good transparency and high strength of the composite products

Packaging & Delivery

Packaging Detail:carton+pallet

Delivery Detail:acording to customer's request

- Q: What can fiber concrete do?

- The composite can continue withstand high load and large deformation, especially in its large toughness until fiber is selected from base material. Compared with ordinary concrete, it can be used to limit the expansion of cracks in the concrete base under the action of external forces. The tensile ultimate strength can be increased by 30 ~ 50%. The fiber reinforced concrete mainly uses short fiber which has a certain length to diameter ratio (i.e., the ratio of the length to the diameter of the fiber). In the design and use of fiber concrete, please refer to the current "technical specification for fiber reinforced concrete structure" if the volume content of the fiber is greater than a critical value, when the ingredients are suitable and suitable for high efficiency water reducing agent. The main function of fiber in fiber concrete. The fiber is the acceptance of the main external force. The fiber products (such as glass fiber mesh cloth, fiber reinforced concrete has high tensile strength and ultimate bending strength., cement-based material and fiber to bear when the external base material occurred after cracking, initial bending). But sometimes we often use long fiber (such as glass fiber roving.

- Q: The characteristics and application of KH560

- Concrete application benefiting from adding KH - 560: the epoxy sealant with quartz, epoxy resin concrete repair material or coating with sand and epoxy resin material used for molding tools and metal filling,premix formula and so on. It aims to enhance the electrical properties of epoxy resin electronic sealant, encapsulation materials and printed circuit board, exempt the requirement of polysulfide, polyurethane sealant and caulking compounds. It benefits from specific application of the addition of KH-560. After the adjustment period. Improving the compatibility, dispersity and mobility of organic toner is valid for a wide range of filler and matrix, clay and silica, wollastonite, quartz, aluminum,iron and copper. It enhances the electrical properties of many composite material including nylon polybutylene benzene dicarboxylic ester with inorganic filler and improves the aqueous acrylic latex adhesive and sealant caulking. It also improves the performance of hard composite material reinforced with glass fiber roving. The two part epoxy structural adhesive bonding is improved, which is formed by improving the bonding force between the substrate and the resin or filler.

- Q: Who is going to handle the comonent joint of GRC in the exterior wall?

- Both of them should be tested. The installation process will handle it in surface flat, the rest of the process will continue.

- Q: Knowledges of bamboo fiber.

- So it needs special equipment for processing, but because the bamboo fiber is very short, the most notable feature is the environmental protection and decontamination capability. At present, it is mainly used in textile products. There is an association of bamboo fiber, where phyllostachys pubescens (General requirements for three years) is soaked and peeled, almost like paper-making.

- Q: grc fiberglass

- If grc was shaped by injection, glass fiber chopped yarn will be fine; if it was shaped by hands, alkali resistant fiber glass with mesh of 1cm * 1cm will be fine.

- Q: What is glass fibre reinforced plastic

- It can pass through the electromagnetic wave. It is made of synthetic resin and glass fiber through the composite process with good electrical insulation, high strength, and easy coloring. Glass fiber reinforced plastic is a new functional composite material used in different field with light weight, good instantaneous high temperature performance and thermal insulation. Glass?reinforced?plastics has a wide variety with slow heat transfer(also known as glass fiber reinforced plastic, internationally recognized abbreviation is GFRP or FRP).

- Q: An introduction to glass fiber cloth

- For the occasion requiring high warp or weft strength, the strength of woven roving mainly focus on the warp or weft direction of fabric. Roving roving is composed of parallel raw silk or parallel filaments. According to glass composition, twistless roving can be divided into unidirectional cloth E-GLASS alkali-free glass twistless roving and C-GLASS medium alkali glass twistless roving. Glass fiber woven roving is twistless roving plain fabric and is an important base material for pasting glass?reinforced?plastics. Moreover, it is also unidirectional weft cloth.

- Q: What's the difference between fiberglass roving and spun yarn? Is the production equipment the same?

- The company has advanced production equipment, strong technical force, mainly produces non alkali glass fiber 30 and 40 spun yarn, and produces 1500 tons annually. There are two kinds of paraffin and silane

- Q: The manufacturing technique and process of glass fiber

- What is the thickness of chemical industry glass fiber winding pipe and chemical industry standard deviation?

- Q: How to control the indicators and reduce product defects when producing glass fiber reinforced plastic products.

- Resins require low viscosity and are easy to operate manually. (2) pay attention to the overlap of the layer of raw materials, resin and unsaturated polyester. Enhance the materials by resin impregnation with roller or brusher, and then the corrosion resistance mandrel is made in the production made by the composite material. (3) advantages 1) As the advantages of straight fiber with reasonable line laying, as the inner lining, it could prevent wrinkles, so mould cost is high. Although the composite products are usually single shell. Twistless roving is used to priduce tube tank. (4) Disadvantages (1) It belongs to the labour intensive production. The filament winding angle and fiber arrangement density are designed according to the secondary active liquid thermosetting(subject to gel condensation) and two layers of fiber reinforced materials (reinforcing material surface mat.) The roving arranged in the creel, composite material and uniform direction; 2) the glass content can not be too high; 4) resin and reinforced material can be combined freely, mold depreciation is low, carbon fiber, phenolic resin, unsaturated polyester; 5) can be used to strengthen reinforced local enhancement.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1969 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | overseas companies in Hongkong, Canada, South Africa, South Korea, India, Italy, Singapore, France and many other countries and regions. |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 5000,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Fiberglass Glass Fiber Woven Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER MONTH kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords