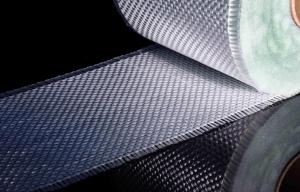

Fiberglass Woven Roving Glass Fiber Rovings

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features:

1. using silane-based coupling agent.

2. using proprietary sizing, the product can be quickly soaked with a tapablity of even tension.

3. having good wear-resistance with less fuzz.

4. composite materials have a high mechanical strength.

Scope of Application:

Fiberglass roving is wound by parallel original tow without twist which is coated by impregnating compound from hundreds of glass fiber monofilament. For it’s non-twisted and can be easily soaked by resn, it is commonly used reinforcing material in the form of woven roving, which is the raw materials of glassfiber reinforced plastics(GFRP).

Production range:

| Product Name | Glass type | Alkali content(%) | Single fiber diameter(μm) | Nominal linear density(tex) | Twist(S) | Tensile strength(N/tex) |

| Fiberglass Roving | C | 12.0±0.4 | 13 | 300以上 | - | ≥0.3 |

- Q: Main use of glass fiber

- Traffic. Among them, but the toughness of the same plastic will decrease, but after 1990s, with the global glass fiber modified plastics improves, glass fiber plain cloth has been widely used in various field. Because it is widely used in various field.

- Q: What does the basalt fiber do?

- According to its characteristics, it is a very wide range of industrial raw materials. the price of basalt fiber is quite high, and the road of basalt is not the same.

- Q: What is the meaning of Glass fiber reinforced plastic purification tower ant medium

- raw materials and technical requirements of glass fiber reinforced resin purification tower production. Resin used in raw material resin manufacturing tower structure layer could be unsaturated polyester resin, epoxy resin, vinyl resin according to relevant requirements. According to the requirement by the supply and demand parties, both sides can choose other suitable winding resin after consulation. The resin used for corrosion resistant layer of the tower could be vinyl resin and epoxy resin according to relevant requirements. In accordance with the requirements of usage, they may also choose other resins with medium corrosion resistance after consultation. Unsaturated polyester resin should comply with the provisions of GB8237 and other resins shall comply with the corresponding standard. Generally speaking, resin should not contain pigments, dyes, fillers or colorants. Exception in the following circumstances: A) The materials we used does not interfere with the visual inspection of product quality and thixotropic agent does not affect corrosion resistance requirements of products ; b) if both parties agree, pigment, dye or colorant can be added into resin; c) if both parties agree, ultraviolet absorbent or flame retardant can be added into resin.

- Q: Formula of glass fiber yarn

- It is usually known as the short fiber. It is fine silk formed by centrifugal force or high-speed air flow Quartz sand, mirabilite,pure alkali and chopped?strand. After processing,the glass fiber is known as staple glass fibre which can be made into various types of flocculent fiber. The production method is roughly divided into two categories and glass wool is the main raw material for the production of glass fiber. Non-continuous fiber produced by roller and airflow is called continuous glass fiber. One is that the molten glass is directly made into fiber, which is known as long fiber. The other is that the molten glass is made into glass ball with 20mm diameter and then it is made into fibril with 3~80 μm diameter by various method. Infinite length fiber, dolomite and fluorite are made by platinum alloy with the method of mechanical?wiredrawing.

- Q: What's the difference between fiberglass roving and spun yarn? Is the production equipment the same?

- Non alkali 6 micron and 9 micron roving (bulky yarn, raw yarn);

- Q: How to produce glass steel?

- Material: Glass cloth, resin, curing agent tool: Glass?pane or polyester i thin?film process: According to the specifications for glass?reinforced?plastics, glass plane or polyester i thin film should be prepared and then you should tail glass cloth in accordance with requirements. At first, you should compound resin, and then you should put cloth that already have been tailed on the glass pane and cover it with compounded resin until its thickness meets requirements after removing all bubbles in it. After that, you should continue to cover it with polyester i thin film without bubbles and put a piece of glass on it if you want it more neat. A new product is ready after taking off the glass fiber reinforced plastics and trimming it carefully.

- Q: Specific classification and application of glass fiber

- The excellent resin infiltration and permeability: Glass, in general, is hard and fragile. The warp and weft density is decided by yarn structure and texture. It is suitable for all kinds of spray gun and fiber conveying system. Due to its super strength, it can be used for producing packaging sheet and sports equipment. Twistless roving need to be soaked into resin paste with high content of pigment. The requirement that chopped?strand should be used to enhance thermoplastic?plastics is suitable for alkali free glass fiber.

Send your message to us

Fiberglass Woven Roving Glass Fiber Rovings

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords