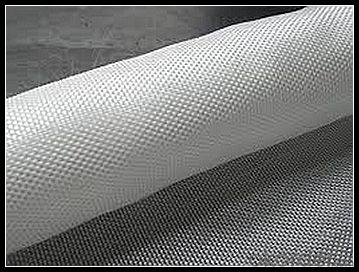

Geotextiles East Africa Ltd Polypropylene Filter Non-Woven Geotextile Farbic Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

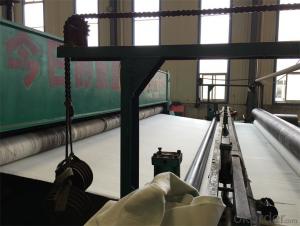

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Weight / Mass: 100g/m2-1500g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP / PET

5) Color: Black , white , grey and other color

Applications

Filtration

gabions and river mattresses

roads

concrete retaining walls.

Separation

the separation of good and poor roadway layer work materials

roads over soft soils.

Roadway lining

provides waterproofing qualities for layer works and wearing courses.

Drainage of

sports fields

railway tracks

behind concrete walls & embankments.

Membrane liner protection

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

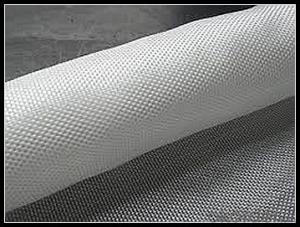

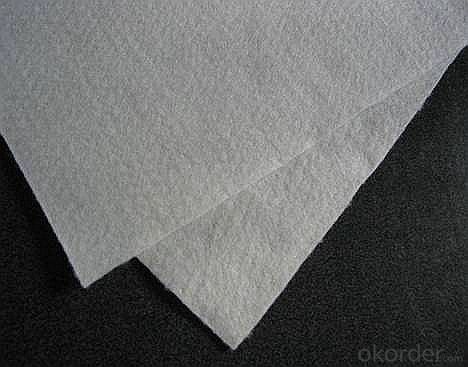

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used for livestock waste management?

- Yes, geotextiles can be used for livestock waste management. Geotextiles are permeable fabrics that can be used to control erosion, filter water, and separate different materials. In the case of livestock waste management, geotextiles can be employed to contain and filter waste runoff, prevent soil contamination, and improve overall water quality. By providing an effective barrier, geotextiles help in preventing the leaching of harmful substances into the environment, thus aiding in the proper management of livestock waste.

- Q: Can geotextiles be used for erosion control in agricultural fields?

- Yes, geotextiles can be used for erosion control in agricultural fields. They are commonly employed to stabilize soil, prevent the loss of sediment, and promote water infiltration. Geotextiles help reduce erosion caused by wind, water, or other environmental factors, thereby protecting the agricultural land and improving its productivity.

- Q: Can plant roots penetrate geotextiles? Which kind of similar material can keep soil and water and let the plant roots pass through it?

- Vegetation network can be, for the best effect of green lawn.

- Q: Geotextile cloth how many square feet

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: How are geotextiles tested for quality assurance?

- Geotextiles are tested for quality assurance through a series of standardized tests that evaluate their physical, mechanical, and hydraulic properties. These tests may include assessing tensile strength, elongation, puncture resistance, water permeability, and filtration efficiency, among others. By conducting these tests, manufacturers can ensure that geotextiles meet the required performance specifications and provide consistent quality for various civil engineering applications.

- Q: Are geotextiles suitable for use in landfill caps?

- Yes, geotextiles are suitable for use in landfill caps. They provide a barrier and filtration system that helps prevent the escape of gases and leachate from the landfill, while also allowing for proper drainage. Geotextiles also help to stabilize the soil and prevent erosion, making them an effective solution for landfill cap construction.

- Q: What are the specifications for geotextiles in gas venting projects?

- The specifications for geotextiles in gas venting projects typically involve requirements such as high permeability, durability, and chemical resistance. They should have a minimum permeability to allow gas to pass through while preventing the migration of fine particles. Additionally, they should be able to withstand the harsh environmental conditions, including exposure to chemicals and UV radiation. Other specifications may include strength, puncture resistance, and compatibility with the surrounding soil or materials used in the gas venting system.

- Q: Can geotextiles be used in shoreline stabilization projects?

- Yes, geotextiles can be used in shoreline stabilization projects. Geotextiles are commonly employed as erosion control measures in shoreline stabilization projects due to their ability to prevent soil erosion, enhance drainage, and provide structural support to the shoreline. They are often used to reinforce slopes, stabilize shorelines, and mitigate the effects of wave action, making them a valuable tool in coastal engineering.

- Q: What are the considerations for geotextile selection in coastal engineering projects?

- When selecting geotextiles for coastal engineering projects, several considerations need to be taken into account. First, the geotextile should have a high tensile strength and durability to withstand the harsh coastal environment, including wave action and fluctuating water levels. It should also possess excellent filtration properties to prevent the migration of fine particles while allowing water to pass through. Additionally, the geotextile's permeability and hydraulic conductivity should be considered to ensure proper drainage and avoid the buildup of hydrostatic pressure. The material's resistance to biological degradation and UV radiation is crucial for long-term performance. Lastly, the geotextile should be compatible with the surrounding materials and easy to install and maintain, minimizing disruptions to the coastal ecosystem and reducing overall project costs.

Send your message to us

Geotextiles East Africa Ltd Polypropylene Filter Non-Woven Geotextile Farbic Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords