Geotextile Non Woven PP Earthwork for Road

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

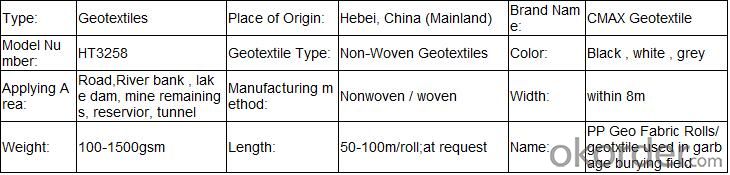

Quick Details

Landfill Geotextile Polyurea

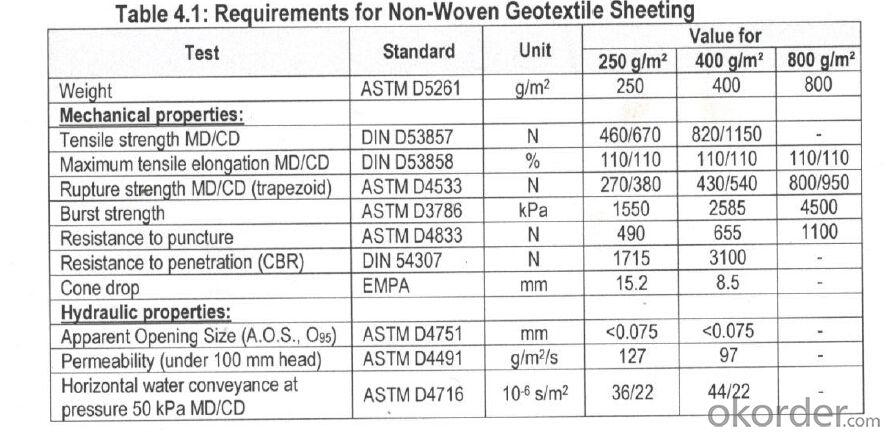

1. Geotextile Specifications

1) Weight / Mass: 100g/m2-1500g/m2 .

2) Width: Within 8 m (1m-8m as request ).

3) Length: 50m-100m/roll (as request).

4) Material: PP / PET .

5) Certificate: CE/ISO9001/ISO14001

6) Manufacturing method: nonwoven / woven.

2. nonwoven geotextile Features :

1) Staple fibers geotextile:

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment.

It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

2) Filament geotextile:

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

3. geotextile Applications

1) Filtration geotextile:

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation geotextile:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3)Adding geotextile:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection geotextile:

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

| Packaging Details: | pallet and design the packing according to client's requests |

| Delivery Detail: | 15-30days after received deposit |

- Q: What is the difference between nonwovens and geotextiles? What is the difference between geotextiles and nonwovens?

- Geotextile is divided into two non-woven geotextile and woven geotextile, non-woven geotextile and acupuncture and spunlace, staple fiber and long fiber. Nonwovens means that the manufacturing process does not require weaving. Geotextiles are used for geotechnical engineering. Geotextile is part of the textile does not require the manufacture can be made, called non-woven geotextile. Non-woven fabrics can be used very broad, like we use the heart of the soft wipes, are non-woven, as well as the hotel put the shoes of the shoes, but also non-woven.

- Q: Geotextile Model PP200-4-750 What does it mean?

- Is the geotextile 200g / ㎡? Geotextile is generally based on the weight per unit area to divide the specifications. Geotextile manufacturers Zhang Ming Chao for you to answer, I hope to help you.

- Q: How do geotextiles affect wildlife habitats?

- Geotextiles can have both positive and negative impacts on wildlife habitats. On one hand, they can enhance and protect habitats by stabilizing soil, reducing erosion, and preventing sedimentation in water bodies. This can benefit various species by preserving their natural habitats and reducing the risk of habitat degradation. On the other hand, improper installation or use of geotextiles can disrupt or alter wildlife habitats, creating barriers to movement, limiting access to resources, or affecting nesting and breeding areas. Therefore, it is crucial to consider the environmental impacts and carefully plan the implementation of geotextiles to minimize any negative effects on wildlife habitats.

- Q: The difference between the construction hdpe impermeable membrane and the geotextile

- Hello, this is two different products Geotextile is not seepage, but the role of filtered water HDPE geomembrane is waterproof. Huazhi geotechnical materials manufacturers to answer your questions

- Q: How do geotextiles help with reinforcement of geotextile bags?

- Geotextiles help with the reinforcement of geotextile bags by providing strength and stability to the bags. They act as a barrier and prevent the soil or other fill material from escaping through the pores of the bags. Additionally, the geotextiles distribute the weight of the fill material evenly, reducing the risk of bulging or bursting of the bags.

- Q: Are geotextiles suitable for high-traffic areas?

- Yes, geotextiles are suitable for high-traffic areas. They are designed to provide stability, erosion control, and reinforcement to the soil, making them an effective solution for areas with heavy foot or vehicle traffic. Geotextiles can help distribute loads and prevent soil compaction, thereby reducing maintenance requirements and extending the lifespan of the area.

- Q: Geotextile detection frequency

- First according to customer requirements grams / square meters, thickness, width, with or without the use of chemical fiber requirements, proofing, and the proofing process parameters, including feed speed, other machines and other parameters of the speed record, Do twenty to ten meters, to test, if qualified, to do so, a lot of bulk, do a few days and then try to seize what the general geotextile manufacturers themselves to prepare several commonly used testing equipment,

- Q: Geotextile need to adjust the humidity before sampling, what does this mean

- probably. For the first time I heard that geotextiles were sampled to be wet.

- Q: Geotextile puncture test standard

- Staple stitch filament piercing filament woven weaving

- Q: What are the different methods of geotextile testing for strength and durability?

- There are several methods used to test the strength and durability of geotextiles. Some common methods include grab tensile strength testing, puncture resistance testing, tear resistance testing, burst strength testing, and UV resistance testing. Each method assesses specific properties of the geotextile to determine its strength and durability in various conditions and applications.

Send your message to us

Geotextile Non Woven PP Earthwork for Road

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords