Geotextile Noir Non-Woven Geotextile Fabric 300gsm for Highway

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

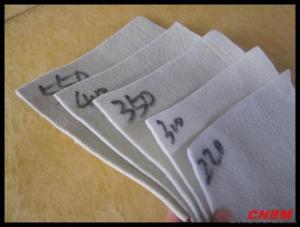

Specification

Product Introduction

The needle-punched non woven geotextile is produced from polyester or polypropylene fiber by differentequipment and technology to get different thickness. The main function is filtration, drainage, reinforcement. It has good impermeability and resistance to deformation

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the purpose of using geotextiles?

- The purpose of using geotextiles is to provide a wide range of functions in different construction and engineering applications. These functions include soil stabilization, erosion control, filtration, drainage, separation, and reinforcement. Geotextiles act as a protective barrier, improving the performance and lifespan of infrastructure projects such as roads, embankments, retaining walls, and landfills.

- Q: We have built a swingset with a built in sandbox. I am looking for geotextile fabric to put under the sandbox to keep weeds & roots out. Any ideas where I can get this from? Local home improvement stores do not stock geotextile fabric. I bought some from a pool supply store for my pool bottom, but they don't sell custom sizes.

- Buy Geotextile Fabric

- Q: Highway on the highway geotextile laying program who has ah?

- The specific construction program, ah, that depends on your specific project, but generally there is such a Hongxiang professional construction staff introduction We usually in the highway geotextile before the laying of the first sprinkle asphalt sticky oil, the amount of about 0.4 ~ 0.6kg / ㎡, and then shop geotextile, and then sprinkle a layer of geotextile in the same type of sticky oil, the amount of about 0.5 ~ 0.6kg / ㎡, also need to pay attention to the temperature when the contact. Geotextile laying before laying a layer of asphalt is to better play the role of anti-seepage, geotextile to adapt to the contact with the asphalt and other materials when the temperature, requiring a higher melting point. The asphalt impregnated geotextile into spray asphalt combined with oil, the geotextile firmly rolled in the above and then spray a thin layer of asphalt, increase the adhesion of the opposite layer, improve water resistance. If the use of paver laying asphalt concrete surface layer, can not spray surface layer of asphalt, only in the bottom to increase the amount of asphalt, control in 1000g / m2 or so. After rolling, the asphalt through its pores through the geotextile reverse osmosis to the surface layer, forming a sealed waterproof layer, but also play a role in reinforcement, improve the new layer of anti-fatigue performance. It is economical and durable.

- Q: Geotextile geotextile geotextile construction geotextile specific application

- Geotextile is a large number of textile materials used in civil engineering in recent years, geotextile, with excellent isolation, filtration, drainage, reinforcement, protection, closed and other functions. Geotextile, is widely used in highways, railway subgrade, airport runway, river bed, dam construction and reclamation, flood control and other major projects. Geotextile use: water conservancy construction: seawall, river embankment, lake embankment project; reservoir reinforcement project; beach reclamation project; flood control. Transportation engineering: soft foundation reinforcement treatment; slope protection; drainage system; green isolation zone. Power plant construction: nuclear power plant base, thermal ash dam, hydropower station and other projects. Port waterway works: port terminals, locks, waterway management and other projects. Other works: tunnel, subway, construction, tailings treatment; landfill and other projects

- Q: How do geotextiles affect water quality?

- Geotextiles can positively impact water quality by acting as a filtration system. They prevent soil erosion, trap sediment, and filter out pollutants from stormwater runoff, thus reducing the amount of contaminants that reach water bodies.

- Q: 200g / m2 geotextile how to enter the inspection test

- In accordance with national standards for testing ah

- Q: How are geotextiles used in railway construction?

- Geotextiles are used in railway construction for various purposes such as erosion control, drainage, and reinforcement. They are placed beneath the ballast to prevent soil erosion and stabilize the trackbed. Geotextiles also help in improving the overall drainage system, reducing the risk of water accumulation and subsequent damage to the railway infrastructure. Additionally, these materials provide reinforcement to the trackbed, enhancing its stability and longevity.

- Q: How do geotextiles improve the performance of pavements?

- Geotextiles improve the performance of pavements by providing reinforcement, stabilization, and filtration. They enhance the strength and load-bearing capacity of the pavement by distributing the applied load more evenly, reducing the likelihood of rutting and cracking. Geotextiles also prevent the intermixing of different layers of pavement materials, maintaining the integrity of the structure. Additionally, they promote drainage and filtration, preventing the accumulation of water and reducing the risk of damage caused by moisture.

- Q: Engineering geotextile non-woven fabrics where the cheapest can buy, where the wholesale market?

- Hello, I am a geotextile manufacturer, quality assurance geotextile, cost-effective, logistics benefits.

- Q: Geotextile cloth can be set what amount of emergency!

- 02,04 Quotations Chapter 9 Geotextile Layers

Send your message to us

Geotextile Noir Non-Woven Geotextile Fabric 300gsm for Highway

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords