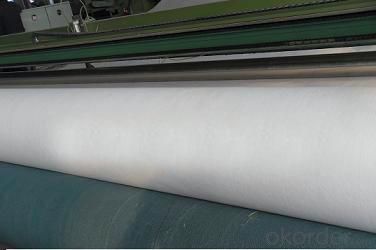

300gsm Bentonite Geotextile Non-Woven Fabrics for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geotextiles Non-Woven Fabrics Images

Geotextiles Non-Woven Fabrics Specification:

Project Model | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Remarks | |||||||

Weight difference on unit area ,% | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | ||||||||

Thickness,mm >= | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 3.5 | 4.2 | 5.3 | 7.6 | 10.0 | 14.2 | ||||||||

Width deviation,% | -0.5 | ||||||||||||||||||

Breaking strength,KN/m >= | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | Longitudinal Transverse | |||||||

Elongation at break,% | 25~100 | ||||||||||||||||||

CBR-test,KN >= | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | ||||||||

Equivalent opening size (EOS) O90,mm | 0.07~0.2 | ||||||||||||||||||

Coefficient of vertical permeability. cm/s | K×(10-1~10-3) | ||||||||||||||||||

Tearing strength,KN >= | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | Longitudinal Transverse | |||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2:Can you send samples to us ?

A2:Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

Q3:What’s your Payment term ?

A3:T/T , L/C , Western Union,Paypal ...

Q4:What’s your manufacture process time ?

A4:Usually within 20 days

- Q: What are the applications of geotextiles in geotechnical engineering?

- Geotextiles have numerous applications in geotechnical engineering, including soil stabilization, erosion control, drainage systems, and filtration. These versatile materials can be used to reinforce weak soils, prevent soil erosion on slopes, and improve the overall stability of various structures, such as roads, embankments, and retaining walls. Additionally, geotextiles can act as filters to separate different soil layers, allowing for proper water drainage and preventing clogging. Overall, geotextiles play a crucial role in enhancing the performance and longevity of geotechnical projects.

- Q: How do geotextiles contribute to soil remediation?

- Geotextiles contribute to soil remediation by acting as a barrier or filter to control erosion, retain sediment, and stabilize the soil. They help to prevent the spread of contaminants, regulate water flow, and enhance the effectiveness of other remediation techniques such as soil vapor extraction or bioremediation.

- Q: Can geotextiles be used in soil erosion control on construction sites?

- Yes, geotextiles can be used in soil erosion control on construction sites. Geotextiles are permeable fabrics that can be placed on the soil surface to prevent erosion by stabilizing the soil and allowing water to pass through while retaining sediment. They are commonly used in construction sites to protect exposed soils from rainfall and runoff, reducing erosion and promoting vegetation growth.

- Q: Can geotextiles be used for drainage?

- Yes, geotextiles can be used for drainage. They are commonly used in civil engineering and construction projects to facilitate water drainage by allowing water to pass through while preventing soil erosion and clogging of drainage systems. Geotextiles can be effective in various drainage applications such as road construction, retaining walls, and sports fields.

- Q: How do geotextiles help with soil stabilization in construction sites?

- Geotextiles help with soil stabilization in construction sites by providing reinforcement and separation between different soil layers. They act as a barrier, preventing the mixing of different soil layers, which helps maintain the stability and strength of the soil. Additionally, geotextiles distribute the load evenly across the construction site, reducing the potential for soil erosion and settling.

- Q: How do geotextiles improve the performance of foundations?

- Geotextiles improve the performance of foundations by providing reinforcement, filtration, and separation. They help distribute loads more evenly, increase the load-bearing capacity, and reduce settlement. Additionally, geotextiles prevent the mixing of different soil layers, control erosion, and enhance drainage, ultimately increasing the stability and longevity of the foundation.

- Q: What are the different geotextile installation techniques in filtration?

- Some of the different geotextile installation techniques in filtration include direct placement, wrap and trench, and sand bag placement. Direct placement involves placing the geotextile directly on the soil surface, while wrap and trench involves wrapping the geotextile around a soil layer or pipe and placing it in a trench. Sand bag placement involves constructing sand bags filled with soil and placing them against the geotextile to hold it in place. These techniques help to ensure proper filtration and prevent soil erosion.

- Q: Can geotextiles be used in temporary erosion control applications?

- Yes, geotextiles can be used in temporary erosion control applications. Geotextiles are commonly used for erosion control as they can stabilize soil and prevent erosion by providing a barrier against water flow while allowing for proper drainage. They are durable, flexible, and can be easily installed and removed, making them suitable for temporary erosion control measures.

- Q: Geotextile filter layer set which quota

- Filter cloth, monofilament filter cloth, polypropylene filter cloth, nylon green monofilament

- Q: What are the environmental considerations of geotextiles?

- Geotextiles have several environmental considerations, both positive and negative. On the positive side, geotextiles can help prevent soil erosion, reduce sedimentation in water bodies, and improve the stability of slopes and embankments, ultimately leading to the preservation of natural habitats. Additionally, geotextiles are often made from recycled materials, such as plastic bottles, which can help reduce waste and promote sustainability. However, there are also potential negative environmental impacts associated with geotextiles. The production and disposal of geotextiles can contribute to pollution, particularly if non-recycled materials are used. Additionally, if not properly installed or maintained, geotextiles can cause unintended consequences, such as altering natural drainage patterns or obstructing the movement of wildlife. Therefore, it is important to carefully assess the environmental implications of using geotextiles and ensure proper installation, maintenance, and disposal practices to mitigate any potential negative impacts.

Send your message to us

300gsm Bentonite Geotextile Non-Woven Fabrics for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords