Geotextile 300g/m2 Short Fiber for Highway

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15000 cm²

- Supply Capability:

- 100000 cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geotextile of Pet 200g/m2 Short Fiber for Highway

Description Geotextile of Pet 200g/m2 Short Fiber for Highway

It is a product made from Synthetic Fibers, non biodegradable, linked together by means of Thermal and Mechanical processes. Characterised by its structure and permeable, Great tensile strength, Tear and Chemical deterioration.

Features Geotextile of Pet 200g/m2 Short Fiber for Highway

high density

loose structure

anti-corrosion

Applications Geotextile of Pet 200g/m2 Short Fiber for Highway

Used in the area of highway, railway

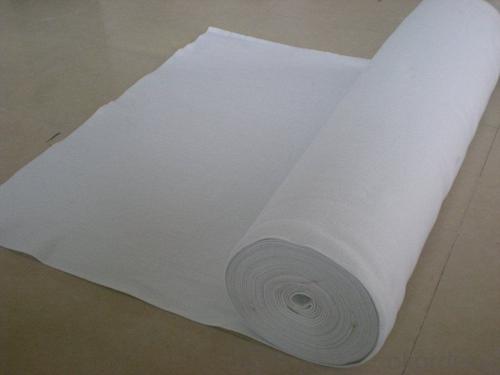

IMages of Geotextile of Pet 200g/m2 Short Fiber for Highway

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 14 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Principle of drainage pipe geotextile

- Principle of drainage pipe geotextile

- Q: Is there a geotextile for reed cultivation?

- Big slope pond words use better, need depth laying, with geomembrane

- Q: Geotextile above allowed to plant grass?

- Geotextile above the grass To protect the slope, then the direct use of three-dimensional vegetation network can not Well! User name is the manufacturer phone! The The

- Q: Are geotextiles commonly used in coastal erosion control?

- Yes, geotextiles are commonly used in coastal erosion control. They are a popular choice due to their ability to stabilize soils and reduce erosion by acting as a barrier against wave action and water flow, while still allowing for water filtration. Geotextiles help to strengthen and protect coastlines, making them an effective solution in coastal erosion control strategies.

- Q: Are geotextiles commonly used in sports field applications?

- Yes, geotextiles are commonly used in sports field applications. They are used to stabilize the soil, control erosion, and improve drainage in sports fields. Geotextiles help to enhance the performance and longevity of the field, making them a popular choice in sports field construction and maintenance.

- Q: There are engineering budgets

- Where are you from where you want to sell

- Q: What are the advantages of using geotextiles in green building design?

- Geotextiles offer several advantages in green building design. Firstly, they help in erosion control by preventing soil erosion and protecting the surrounding environment. Secondly, geotextiles act as a filtration system, promoting water drainage while retaining fine particles, thus enhancing water quality. Additionally, they provide stability and reinforcement to the soil, ensuring the structural integrity of the building's foundation. Geotextiles also aid in weed control by preventing the growth of unwanted vegetation. Lastly, these materials are often made from recycled materials, making them an eco-friendly choice for sustainable construction practices.

- Q: Can geotextiles be used in shoreline erosion control projects?

- Yes, geotextiles can be effectively used in shoreline erosion control projects. Geotextiles are permeable fabrics that can be installed along shorelines to stabilize the soil and prevent erosion caused by waves and currents. They can be used as a layer to separate the soil from the water, allowing for water filtration while reducing soil erosion.

- Q: Can geotextiles be used in pond and lake liners?

- Yes, geotextiles can be used in pond and lake liners. Geotextiles are commonly used as a protective barrier or filtration layer in liner systems for ponds and lakes. They help to prevent soil erosion, control water flow, and provide stability to the liner.

- Q: Geotextile cloth can be set what amount of emergency!

- Borrow the municipal or highway quota, follow the actual price adjustment, or direct b: 001 input price (this price is included in the artificial material machinery sets of quotas is a professional term in the project budget.In the project budget, The basic principle of the budget is: to calculate the amount of engineering, and then multiplied by the price, and ultimately draw the total cost of the project, the total cost

Send your message to us

Geotextile 300g/m2 Short Fiber for Highway

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15000 cm²

- Supply Capability:

- 100000 cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords