Geotextile for Slope Protection,High Strength Coastal Use Woven Geotextile

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geotextile for Slope Protection,High Strength Coastal Use Woven Geotextile

Desciriptions:

PP Woven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications. It separates, stabilizes, and reinforces soils and allos allows for filtration. Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

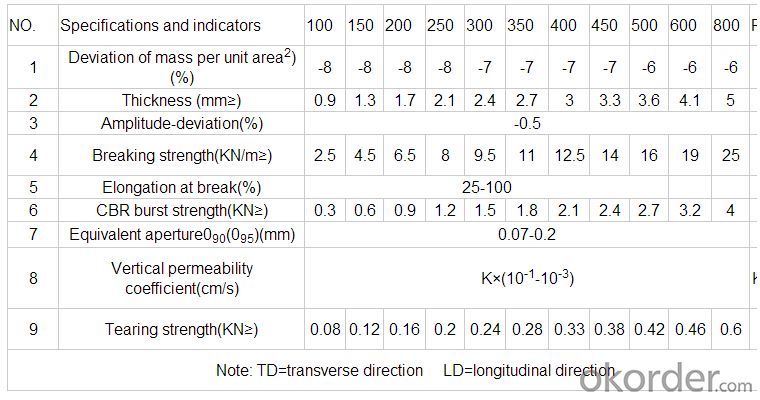

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

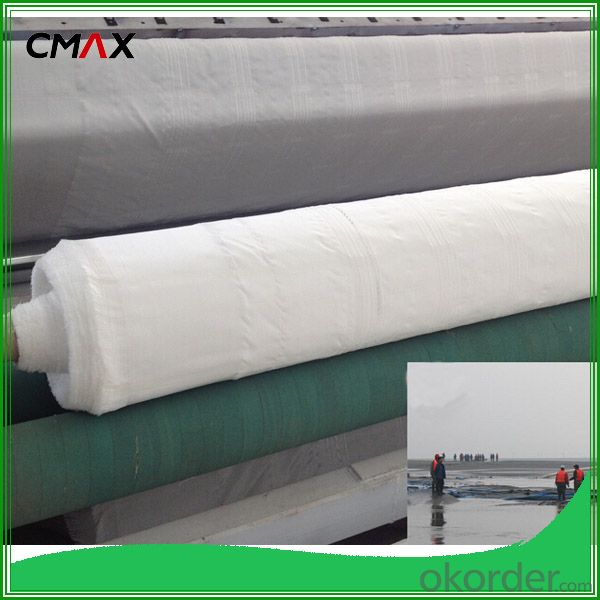

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the main functions of geotextiles?

- The main functions of geotextiles include filtration, separation, reinforcement, and drainage in various civil engineering and construction applications.

- Q: What are the installation guidelines for geotextiles used in erosion control blankets?

- The installation guidelines for geotextiles used in erosion control blankets typically involve the following steps: 1. Site preparation: Ensure that the area where the erosion control blanket will be installed is properly graded and free of any debris or vegetation. 2. Unroll the geotextile: Start by unrolling the geotextile fabric along the slope or area where erosion control is needed. Make sure to overlap the fabric by the specified amount to ensure complete coverage. 3. Secure the fabric: Use stakes or landscape pins to secure the geotextile to the ground, especially at the edges and corners. This will prevent it from shifting or being displaced during installation or heavy rainfall. 4. Seam connection: If multiple rolls of geotextile fabric are required, ensure that they are properly overlapped and securely connected using a recommended seam connection method. This will ensure a continuous and seamless coverage. 5. Anchoring: In certain cases, additional anchoring may be required to provide extra stability. This can include using sandbags, rocks, or other suitable materials along the edges or across the surface of the geotextile fabric. 6. Vegetative cover: If the erosion control blanket is designed to support vegetation growth, follow the recommended guidelines for seed or plant installation. This may involve spreading seeds or planting live vegetation through the geotextile fabric. It is important to note that these guidelines may vary depending on the specific erosion control blanket and geotextile manufacturer, as well as the site and project requirements. It is always recommended to refer to the manufacturer's installation instructions and consult with a professional engineer or erosion control specialist for proper installation and best results.

- Q: This is a large sample of gravel anti-filter how this project count

- Lack of slope and total length, can not accurately calculate the amount of engineering. Approximate estimates of cross-sectional area, then only a few simple graphics: clay tamping (rectangular), coarse gravel (trapezium), gravel and gravel (zoned plus parallel quadrilateral), geotextile (four sections)!

- Q: Today someone told me about a boyfriend, said to be geotextile. I wonder, geotextile cloth is what cloth? Is there there? Why is it used More

- Geotextile geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, isolation, reinforcement protection, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Divided into: non-woven geotextile, a textile geotextile (reinforced geotextile), warp knitted geotextile with demand can contact: Fang Lingyan Tel:

- Q: Can geotextiles be used in coastal erosion control projects?

- Yes, geotextiles can be used in coastal erosion control projects. They are often employed as a part of erosion control systems to stabilize the soil and prevent erosion in coastal areas. Geotextiles are permeable fabrics that are placed on the ground or underwater to reinforce and protect the soil, while allowing water to pass through. They can help in maintaining beach profiles, preventing sediment loss, and reducing wave energy, thus providing effective coastal erosion control.

- Q: Can geotextiles be used in road shoulder stabilization?

- Yes, geotextiles can be used in road shoulder stabilization. Geotextiles are often used to reinforce and stabilize road shoulders by providing separation, filtration, and reinforcement functions. They help prevent erosion and improve the strength and stability of the road shoulder, making it suitable for various types of traffic loads.

- Q: Which big god has the relevant documents? bow down!

- Geotechnical materials in the application of seepage in the drainage, the specific is to protect the blind ditch.

- Q: What are the different geotextile permeability testing standards?

- Some of the different geotextile permeability testing standards include ASTM D4491, ISO 11058, and EN ISO 12958. These standards provide guidelines for conducting tests to determine the hydraulic conductivity and permeability characteristics of geotextile materials.

- Q: Can geotextiles be used in green roof construction?

- Yes, geotextiles can be used in green roof construction. They are commonly used as a separation layer between the growing medium and the drainage layer, preventing the two layers from mixing while allowing water to drain freely. Geotextiles also help to retain moisture within the growing medium, providing an ideal environment for plant growth on green roofs.

- Q: How do geotextiles improve the performance of geopipes?

- Geotextiles improve the performance of geopipes by acting as a filter and separator between the soil and the pipe. They prevent the intrusion of fine particles into the pipe, which can clog it and reduce its flow capacity. Additionally, geotextiles enhance the stability of the soil around the pipe, preventing soil erosion and maintaining the overall integrity of the system.

Send your message to us

Geotextile for Slope Protection,High Strength Coastal Use Woven Geotextile

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords