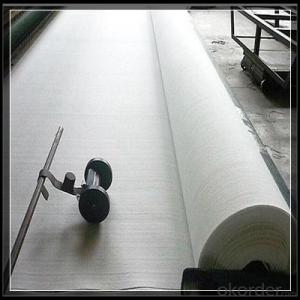

Geotextiles for Erosion Control - High Performance Non-Woven Geotextile Industrial Nonwoven Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Application

1. Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2. Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3. Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4 .Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5. Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6 Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.)

Non-woven geotextiles are ideal for use in foundation drainage, behind retaining walls and gabions, in sub-drains, and under rip-rap & armourstone.

Most environmental codes and regulations will require geosynthetic linings for landfill and waste management projects.

Our non-woven geotextile fabrics contain high-grade polypropylene fibres to provide physical strength and excellent fluid management properties.

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles contribute to soil remediation?

- Geotextiles contribute to soil remediation by providing a physical barrier that prevents soil erosion, filters out contaminants, and promotes vegetation growth. They help in stabilizing slopes, controlling sediment runoff, and improving the overall quality of the soil by allowing natural processes to occur while minimizing the spread of pollutants.

- Q: How do geotextiles affect visual aesthetics?

- Geotextiles, being a synthetic fabric, can often blend seamlessly with the surrounding environment due to their neutral color and texture. This can enhance the visual aesthetics of an area by creating a more cohesive and harmonious appearance. Additionally, geotextiles can be used to stabilize soil and prevent erosion, leading to a more visually pleasing and well-maintained landscape.

- Q: What are the uses of acupuncture geotextiles?

- Hello! You said there are two, the first is staple acupuncture non-woven geotextile, it is widely used in railways, highways, sports grounds, dam dams, water and soil construction, tunnels, coastal beaches, reclamation, environmental protection projects! The second is filament spunbonded acupuncture non-woven geotextile, which is widely used in the bottom of the landfill site, slope, closure of the reinforcement and protection, water conservancy project dam dam and slope of the filter, channel Isolation, seepage, road, rail, airport runway foundation isolation, filter ~ drainage! Soil slope, retaining wall and road reinforcement ~ drainage, port engineering soft foundation treatment, beach reclamation, port terminals and anti-slope reinforcement ~ drainage! I hope to help you, specializing in the production of geotechnical materials to answer!

- Q: SNG400-3.5 geotextile is what model

- SNG400-3.5 refers to the national standard polyester staple acupuncture non-woven geotextile 400g / ㎡, width 3.5m. The index code for staple acupuncture nonwoven geotextiles is generally SNG / (1) (2) / (3) - (4) / (5). (1) that the use of raw materials fiber code: PET-polyester, PP-polypropylene, PA-nylon, PV-vinylon, PE-Ethylene (conventional polyester are generally vacant omitted code) (2) that polyester staple fiber non-woven Geotextile per unit area weight. (3) that the composite products in the polyester staple fiber non-woven geotextile weight per unit area, non-composite product vacancies. (4) width, expressed in meters (5) production department number: can express the product more specific characteristics, functions, varieties, sequences, etc., the general vacancy. For example, a 3.5m wide 400g / ㎡ polyester staple fiber nonwoven geotextile representation can be SNG / PET400-3.5, can also be expressed as SNG400-3.5

- Q: What are the maintenance requirements for geotextile-reinforced slopes?

- The maintenance requirements for geotextile-reinforced slopes typically involve regular inspections, monitoring for signs of erosion or instability, and addressing any identified issues promptly. This may include repairing or replacing damaged geotextiles, reinforcing the slope with additional materials if necessary, and implementing erosion control measures such as vegetation or drainage systems. Regular maintenance and timely interventions are essential to ensure the long-term stability and effectiveness of geotextile-reinforced slopes.

- Q: Are geotextiles commonly used in agriculture?

- Yes, geotextiles are commonly used in agriculture. They serve various purposes such as weed control, soil stabilization, erosion prevention, and drainage management. Geotextiles help improve crop yield, reduce maintenance costs, and promote sustainable farming practices.

- Q: What is the representative batch of geotextile?

- Geotextile batch is 2000 square meters.

- Q: What are the different guidelines for geotextile installation in erosion control projects?

- There are several guidelines for geotextile installation in erosion control projects. Firstly, it is important to properly prepare the soil surface by removing all vegetation, debris, and loose soil. The geotextile should then be placed directly on the prepared surface, ensuring that it is smooth and free of wrinkles or folds. It is crucial to overlap the geotextile seams by the manufacturer's recommended distance and secure them with staples or other appropriate fasteners. Additionally, the geotextile should be anchored using anchor trenches or pins to prevent movement. Finally, proper maintenance and inspection of the geotextile should be carried out regularly to ensure its effectiveness in erosion control.

- Q: How do geotextiles improve the stability of slopes?

- Geotextiles improve the stability of slopes by providing reinforcement and erosion control. They are placed within the slope to enhance its strength, prevent soil erosion, and increase overall stability. The geotextiles act as a barrier, distributing the forces exerted on the slope and reducing the potential for sliding or failure. Additionally, they can promote water drainage, preventing the accumulation of excess water that may weaken the slope. Overall, geotextiles play a crucial role in enhancing the stability and longevity of slopes.

- Q: What are the different geotextile weight classes and their applications?

- Geotextiles are categorized into different weight classes based on their mass per unit area. These weight classes range from lightweight to heavyweight. Lightweight geotextiles, usually less than 200 grams per square meter (gsm), are commonly used in erosion control applications, such as slope stabilization and vegetation support. They provide filtration and separation functions while allowing water to pass through. Medium-weight geotextiles, typically ranging from 200 to 400 gsm, are often employed in applications like road stabilization, embankment reinforcement, and subgrade separation. They offer a balance between strength and permeability, ensuring proper drainage and preventing soil movement. Heavyweight geotextiles, exceeding 400 gsm, are primarily used in applications requiring high strength and durability. These include shoreline protection, coastal engineering, and land reclamation projects. They provide robust reinforcement and act as a barrier against erosion and wave action. The choice of geotextile weight class depends on the specific engineering requirements of the project, such as soil conditions, anticipated loads, and desired drainage characteristics.

Send your message to us

Geotextiles for Erosion Control - High Performance Non-Woven Geotextile Industrial Nonwoven Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords