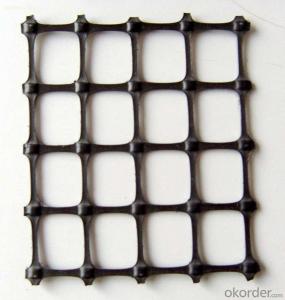

Geocells Material Biaxial Geogrid for Dams in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

WEIGHT

300G/SQM

500G/SQM

ELONGATION AT BREAK

3%

TENSILE STRENGTH IN KNOT

5KN/M

10KN/M

WIDTH:

1--6M

CNBM offers BaseGrid biaxial geogrids for base reinforcement. They are manufactured by welding or stitching together two layers of extruded, polypropylene, flexible geogrids to create a continuous sheet that will not separate. The two grids are offset before welding or stitching, creating a stable, continuous sheet with random-sized apertures for improved soil interaction.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geogrids help in reducing the risk of pavement rutting?

- Geogrids help in reducing the risk of pavement rutting by providing structural reinforcement to the pavement layers, improving their stability and preventing the formation of ruts. They distribute the load across a wider area, reducing the stress on the pavement surface and minimizing the deformation caused by heavy traffic or repeated loading. This helps to maintain the integrity of the pavement, increasing its lifespan and reducing the need for costly repairs or maintenance.

- Q: What are the factors that affect the long-term oxidation resistance of geogrids?

- The factors that affect the long-term oxidation resistance of geogrids include the type of polymer used in the geogrid manufacturing, the quality of the polymer, the exposure to UV radiation, temperature fluctuations, and the presence of chemicals or pollutants in the surrounding environment.

- Q: What is the typical width of a geogrid roll?

- The typical width of a geogrid roll is usually around 4 to 6 feet.

- Q: How to fill in the geogrid evaluation form

- What kind of geosynthetics are you looking at?

- Q: How do geogrids improve the performance of reinforced soil structures?

- Geogrids improve the performance of reinforced soil structures by providing additional strength and stability. They act as a reinforcement material, distributing the forces and loads evenly throughout the structure. This helps to prevent soil erosion, slope failure, and settlement, ultimately enhancing the overall durability and longevity of the structure.

- Q: Glass fiber grating with large pulling force for Expressway

- Fiberglass geogrid is mainly used for old road reconstruction, the main purpose is to reduce reflection cracks.

- Q: Can geogrids be used in road construction?

- Yes, geogrids can be used in road construction. Geogrids are often used as a reinforcement material in road construction projects to improve the strength and stability of the roadbed. They help to distribute the load and prevent the movement of soil or aggregate materials, thereby enhancing the longevity and performance of the road.

- Q: Glass steel grille is how to produce

- Production process of FRP grid:Preparation of mold - Preparation of mixed resin - glass fiber yarn - (or at the same time) pouring resin and exhaust bubble - mold heating, product curing - mold - finishing - Inspection packaging.

- Q: What is the purpose of using the three - way geogrid in the gravel layer

- Or the design requirements are back folding 30CM

- Q: What are the advantages of using geogrids in ground improvement for load transfer platforms?

- Geogrids offer several advantages in ground improvement for load transfer platforms. Firstly, they enhance soil stability by reinforcing the ground, thereby increasing its load-bearing capacity. This allows for the construction of larger and more robust load transfer platforms, capable of supporting heavy loads. Additionally, geogrids help to distribute the load more evenly across the platform, reducing the risk of localized failures or settlements. Moreover, these geosynthetic materials are durable and resistant to degradation, ensuring the longevity and effectiveness of the ground improvement solution. Overall, geogrids provide a cost-effective and efficient method for strengthening and stabilizing the soil, resulting in improved performance and safety of load transfer platforms.

Send your message to us

Geocells Material Biaxial Geogrid for Dams in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords