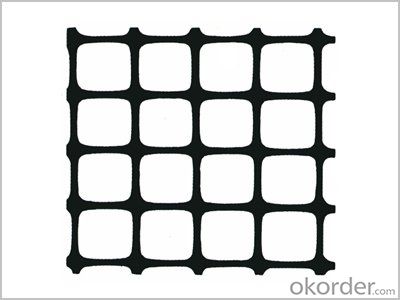

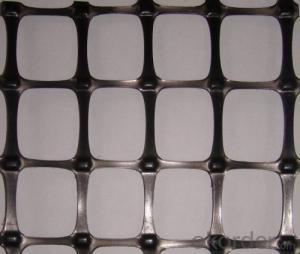

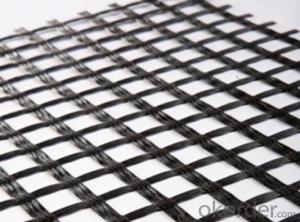

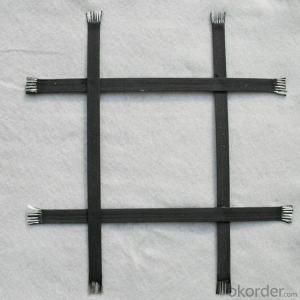

Biaxial Geogrids for Reinforcement and Separation in Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Geogrids are flat structures in polymer (usually high density polyethylene or polypropylene) that are extruded and then pulled: this may be done in one direction (mono-oriented geogrids), or in the two main directions (bi-oriented geogrids). They are used in soil and road paving reinforcement. Biaxial geogrids are designed to have roughly the same tensile strength in both directions and to distribute loads over a wider area, increasing the load capacity of the soil. Base reinforcing geogrids interlock with the aggregate to confine the base and reinforce the subgrade. In paved or unpaved applications, they reduce rutting and help maintain the desired aggregate depth.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geogrids be used in reinforcement of bridge abutments on expansive soils?

- Yes, geogrids can be used in reinforcement of bridge abutments on expansive soils. Geogrids are effective in providing soil stabilization and preventing soil movement, which is particularly important in areas with expansive soils that tend to expand and contract with moisture content changes. By using geogrid reinforcement, the bridge abutments can be better protected against potential soil movement, reducing the risk of structural damage.

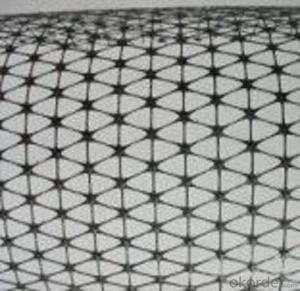

- Q: What is the difference between woven and non-woven geogrids?

- Woven geogrids are made by weaving polyester or polypropylene yarns together, resulting in a strong and flexible grid structure. On the other hand, non-woven geogrids are manufactured by bonding or needle-punching synthetic fibers, creating a random network of fibers. The main difference lies in their structure and manufacturing process, which influences their mechanical properties and application. Woven geogrids tend to have higher tensile strength and are suitable for stabilizing soil in applications such as road construction, while non-woven geogrids are more commonly used for erosion control and filtration purposes.

- Q: Are geogrids effective in reducing differential settlement in foundations?

- Yes, geogrids are effective in reducing differential settlement in foundations. Geogrids provide added stability and reinforcement to the soil, distributing the load more evenly and reducing differential settlement. They help to prevent differential movement between different areas of the foundation, ensuring more uniform settlement and minimizing potential structural damage.

- Q: How do geogrids help in reducing the risk of pavement rutting?

- Geogrids help in reducing the risk of pavement rutting by providing structural reinforcement to the pavement layers, improving their stability and preventing the formation of ruts. They distribute the load across a wider area, reducing the stress on the pavement surface and minimizing the deformation caused by heavy traffic or repeated loading. This helps to maintain the integrity of the pavement, increasing its lifespan and reducing the need for costly repairs or maintenance.

- Q: Can geogrids be used in riverbank protection projects?

- Yes, geogrids can be used in riverbank protection projects. Geogrids provide reinforcement and stability to the soil, preventing erosion and slippage along the riverbank. They are effective in enhancing the strength of the soil while allowing for proper drainage. Geogrids can be installed easily and are a cost-effective solution for protecting riverbanks against erosion and maintaining their stability.

- Q: Can geogrids be used in underground mining operations?

- Yes, geogrids can be used in underground mining operations. Geogrids are a type of geosynthetic material that provide reinforcement and stability to soil or rock structures. In underground mining, geogrids can be used for ground support and stabilization, preventing collapses and enhancing safety. They can also be used for reinforcing roadways, tunnels, and other underground structures, improving their load-bearing capacity and longevity.

- Q: What is the effect of cyclic loading on geogrid behavior?

- Cyclic loading on geogrid behavior can lead to a reduction in its tensile strength and stiffness over time. This is primarily due to the accumulated damage and deformation caused by repeated loading and unloading cycles. The degradation in geogrid performance can affect its ability to provide reinforcement and stability in various geotechnical applications, such as retaining walls or road pavements. Therefore, careful consideration of cyclic loading effects is necessary when designing and evaluating geogrid installations to ensure their long-term effectiveness and durability.

- Q: Are geogrids suitable for use in high-temperature environments?

- Geogrids are generally not suitable for use in high-temperature environments as they can experience thermal degradation and loss of mechanical properties.

- Q: Can geogrids be used in subgrade stabilization?

- Yes, geogrids can be used in subgrade stabilization. Geogrids are commonly employed in civil engineering projects to enhance the stability of subgrade soils. They provide reinforcement and distribute loads, reducing the potential for soil movement and settlement. Geogrids are effective in improving the strength and load-bearing capacity of subgrade soils, making them suitable for subgrade stabilization applications.

- Q: What are the properties and characteristics of geogrids?

- Geogrids are synthetic materials, typically made from polymer materials such as polyethylene or polypropylene, that are used in civil engineering and construction projects. These materials possess several important properties and characteristics. Firstly, geogrids have high tensile strength, which allows them to effectively distribute loads and provide structural reinforcement to the soil. They also have excellent resistance to chemical and biological degradation, making them suitable for long-term applications in various environmental conditions. Geogrids are lightweight, flexible, and easy to handle, making installation and transportation more convenient. Additionally, these materials exhibit low elongation and creep characteristics, ensuring long-term stability and performance. Overall, geogrids offer superior soil stabilization, erosion control, and reinforcement properties, making them valuable in a wide range of geotechnical and construction projects.

Send your message to us

Biaxial Geogrids for Reinforcement and Separation in Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords