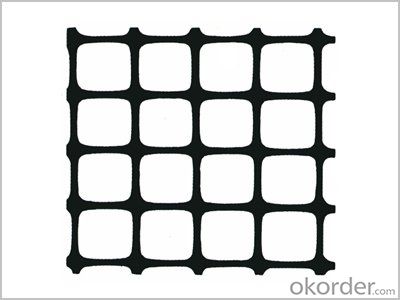

Geocells Material Biaxial Geogrid for Civil Engineering in Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

The geogrid elements vary in polymer type and cross-sectional dimensions. They can sometimes change shape and dimensions within their length. Geogrids are either integrally manufactured (punched and drawn sheets; or extruded), ultrasonically or adhesive bonded strips, or joined in a knitting or weaving process and then coated. Polymer types include polyethylene, polypropylene or high tenacity polyester that has been coated.

Extruded Geogrids are flat structures in polymer (usually high density polyethylene or polypropylene) that are extruded and then pulled: this may be done in one direction (mono-oriented geogrids), or in the two main directions (bi-oriented geogrids). They are used in soil and road paving reinforcement. Slopes and subgrades with rails are a serious problem in railroad construction. Under high pressure the layers slide and deform consequently causing rail deformation, which requires closing railroad segments for a long time. Geogrid application allows carrying out comlex repair operations of the necessary road segment in shortest time (which is very essential in transportation).

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the difference between woven and non-woven geogrids?

- The main difference between woven and non-woven geogrids lies in their construction and composition. Woven geogrids are made by weaving tensile elements together, forming a grid-like structure. On the other hand, non-woven geogrids are created by bonding or needle-punching fibers together to form a random arrangement. Woven geogrids are typically stronger and have higher tensile strength due to their interlocking design. They are commonly used in applications that require high load-bearing capacity, such as stabilizing soil for road construction or reinforcing retaining walls. Non-woven geogrids, although less strong, offer excellent filtration and separation properties, making them suitable for erosion control, drainage systems, and preventing soil migration. In summary, woven geogrids are stronger and ideal for heavy-duty applications, while non-woven geogrids excel in filtration and separation tasks. The choice between the two depends on the specific needs of the project and the desired performance characteristics.

- Q: How do geogrids improve the performance of geotechnical structures?

- Geogrids improve the performance of geotechnical structures by enhancing their load-bearing capacity, reducing soil erosion, and providing stability. These synthetic materials are used to reinforce soil, increasing its strength and preventing it from shifting or settling. By distributing the load more evenly, geogrids minimize the potential for structural failure and improve overall stability. Additionally, they help to control soil erosion by stabilizing slopes and retaining walls, reducing the risk of landslides and erosion-related damage.

- Q: Can geogrids be used in ground stabilization for telecommunications infrastructure?

- Yes, geogrids can be used in ground stabilization for telecommunications infrastructure. Geogrids are commonly used to reinforce soil and provide stability to various types of infrastructure, including telecommunications installations. They can effectively distribute loads, prevent soil erosion, and enhance the overall strength and stability of the ground.

- Q: Glass fiber grille material.

- In order to protect the glass fiber, improve the overall performance of the use of special coating treatment process of the composite materials.

- Q: What are the different installation techniques for geogrids?

- There are several installation techniques for geogrids, including mechanical connection, soil confinement, and anchorages. Mechanical connection involves attaching the geogrid to the soil or other structures using methods like staples, nails, or screws. Soil confinement refers to placing the geogrid within the soil mass to enhance its stability and prevent lateral movement. Anchorages are used to secure the geogrid by embedding it into a stable structure or using specialized anchoring devices.

- Q: Can geogrids be used in mining tailings management?

- Yes, geogrids can be used in mining tailings management. Geogrids are commonly used in the mining industry to reinforce soil and stabilize slopes. In the context of tailings management, geogrids can be used to improve the stability and strength of tailings dams or containment structures, preventing erosion and potential environmental hazards. Additionally, geogrids can enhance the consolidation and dewatering of tailings, facilitating their proper management and reducing the risk of environmental contamination.

- Q: Are geogrids suitable for use in reinforced steep slopes?

- Yes, geogrids are suitable for use in reinforced steep slopes. Geogrids are engineered materials that provide stability and reinforcement to slopes by distributing and transferring loads. They effectively improve soil strength and prevent erosion, making them an ideal solution for reinforcing steep slopes and enhancing their stability.

- Q: How do geogrids improve the stability of steep slopes?

- Geogrids improve the stability of steep slopes by providing reinforcement and support to the soil through their tensile strength. When installed horizontally or at an angle within the soil, geogrids help distribute the load and reduce the potential for slope failure by increasing the soil's resistance to sliding and erosion. Additionally, they enhance the overall stability by preventing excessive soil movement and promoting better compaction, thereby increasing the slope's shear resistance.

- Q: How is the strength of a geogrid determined?

- The strength of a geogrid is determined through various laboratory tests and calculations that evaluate its tensile strength, creep resistance, and other mechanical properties. These tests involve applying force to the geogrid in different directions to measure its ability to withstand pulling, stretching, or shear forces. The results of these tests help determine the geogrid's strength and its suitability for specific applications in civil engineering and soil stabilization projects.

- Q: Which is the high price of steel plastic geogrid and fiberglass geogrid

- If you take the worst plastic steel and the best glass fiber ratio, the latter price is high

Send your message to us

Geocells Material Biaxial Geogrid for Civil Engineering in Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords