Geocells for Driveways - Polyester Geogrid with PVC Coating (Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

1. Introduction of Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

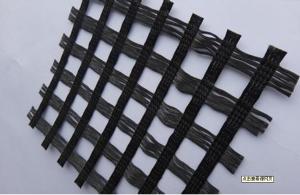

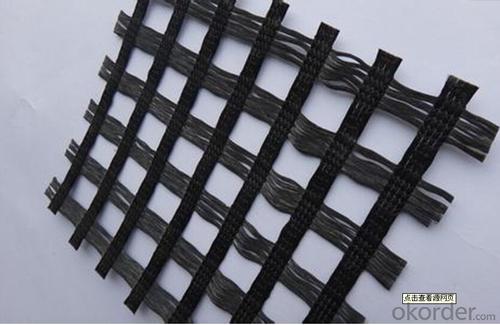

High strength polyester warpknitting geogrid adopts high strength, high modulus, and low shrinkage twisting industrial polyester fiber as raw material. It is warp knitted with oriented structure and in the condition of no bending among warp and weft direction.

Its crossing points are bundled and bended together by high strength long polyester fiber forming tough conjunction. Then it forms into mesh size product after coated with high quality watersoluble PVC which improves its strength, various technical standards and gives full play of its mechanical property.

2. Performance of Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

High tensile strength

Low elongation

Excellent temperature resistant

Good anti-aging

Good alkali-resistance

3. Application of Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

Strengthening soft roadbed of high-class roads and high speed railways, separating different subgrade soil material.

Using in reclamation engineering, dam, landslides and retaining wall.

Enhancing various roadbeds.

Strengthening soft roadbed of airport.

4. Packing and Delivery of Polyester Geogrid with PVC Coating(Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

- Q: Can geogrids be used for reinforcement in railway track construction?

- Yes, geogrids can be used for reinforcement in railway track construction. Geogrids are durable and flexible materials that can effectively distribute loads and provide stability to the railway track, reducing the risk of deformation and settlement. They can enhance the overall performance and lifespan of the track, making them a suitable reinforcement option in railway track construction projects.

- Q: How do geogrids help in reducing the risk of pavement rutting?

- Geogrids help in reducing the risk of pavement rutting by providing reinforcement and stabilization to the base layer of the pavement. They distribute the load more evenly, preventing localized stress and deformation. This helps to maintain the integrity and structural stability of the pavement, reducing the potential for rutting, cracking, and other forms of distress.

- Q: What are the general laying methods of Geogrid

- Along the longitudinal laying, U nail fixed joint part, 15 cm, with tie rods or connection

- Q: What are the factors that affect the design of geogrid-reinforced structures?

- There are several factors that affect the design of geogrid-reinforced structures. Some of the key factors include the type and properties of the soil, the magnitude and direction of the applied loads, the desired level of stability and performance, the environmental conditions, and the available construction materials and methods. Additionally, factors such as the cost, aesthetics, and maintenance requirements may also influence the design decisions for geogrid-reinforced structures.

- Q: What is the typical weight of a geogrid roll?

- The typical weight of a geogrid roll can vary depending on its size and material, but it typically ranges from 50 to 100 pounds.

- Q: Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method?

- Because the main force borne by the steel wire, if it is false, the consequences can be disastrous ah!

- Q: Geogrid test items: what is the point of the joint point?

- The conventional test items of geogrid are tensile strength, elongation, and welding point peeling force.So it is not feasible for you to put the waterproof material on the geogrid.

- Q: What are the factors that affect the cost-effectiveness of geogrid-reinforced structures?

- There are several factors that can affect the cost-effectiveness of geogrid-reinforced structures. Firstly, the type and quality of the geogrid material used can significantly impact the overall cost. Higher-quality geogrids may initially be more expensive but offer better long-term performance, potentially reducing maintenance and repair costs over time. Additionally, the design and engineering of the structure play a crucial role. Properly designed geogrid-reinforced structures can optimize material usage and minimize construction costs. The expertise and experience of the engineers and contractors involved also contribute to the cost-effectiveness, as their knowledge can help avoid unnecessary expenses and ensure efficient construction. The specific site conditions, such as soil characteristics and slope stability, are also important factors. Geogrids are typically used to enhance soil stability, so the suitability of the soil for reinforcement and the extent of reinforcement required can impact costs. Difficult terrain, challenging access, or the need for additional site preparation can also increase costs. Lastly, the lifespan and durability of geogrid-reinforced structures should be considered. While geogrids are designed to be long-lasting, factors like environmental conditions, loading requirements, and proper installation can affect their performance. Investing in high-quality materials and proper installation methods may initially increase costs but can result in longer service life and reduced maintenance expenses in the long run.

- Q: How is a geogrid different from other geosynthetics?

- A geogrid is a type of geosynthetic that is specifically designed to provide reinforcement and stabilization to soil and other materials. Unlike other geosynthetics such as geotextiles or geomembranes, which primarily function as filters or barriers, a geogrid is characterized by its grid-like structure that offers high tensile strength and interlocking capabilities. This unique design allows geogrids to distribute loads more efficiently, enhance soil stability, and prevent the lateral spreading of materials.

- Q: In the middle of geogrid foundation treatment process is belongs to the concealed work it

- After the completion of the project is not visible to the process or project site, are known as the hidden works, so the geogrid must belong to the hidden works

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Geocells for Driveways - Polyester Geogrid with PVC Coating (Warp Knitting) 13% Elongation/30KN*30KN-200KN*120KN

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords