Geocells Market - PVC Coated Polyester Geogrid Warp Knitting for Railway

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Geogrids | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX

|

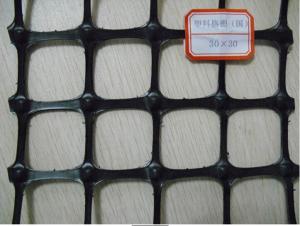

Model Number: | polyester geogrid | Material: | Polyester | note: | plastic geogrid |

tensile strength: | 15,20,25,30,40,50,60,70,80,90,100,110,120 and so on | mesh size: | 36mm*36mm | roll size: | 3.95*100m or 3.95*50m |

certificate: | CE ISO |

Packaging & Delivery

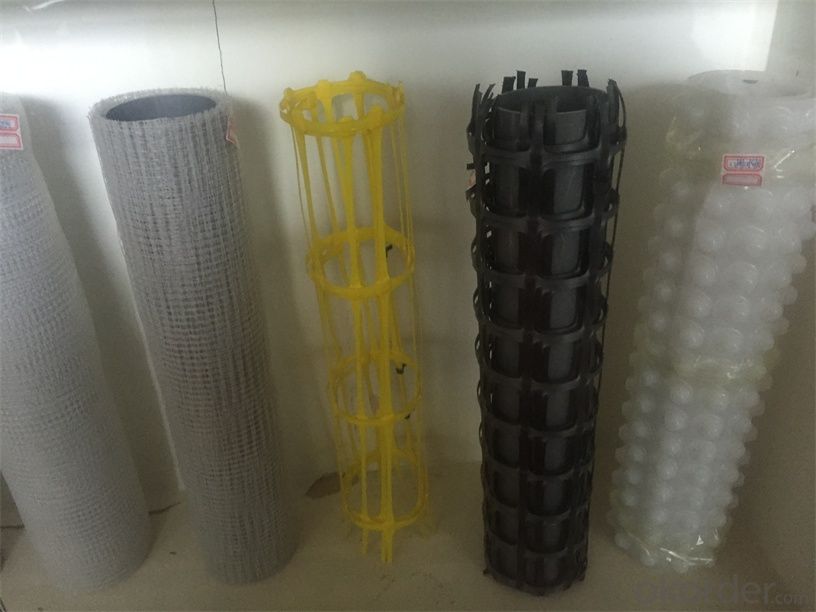

Packaging Details: | plastic geogrid packing in roll or customized |

Delivery Detail: | 5 days |

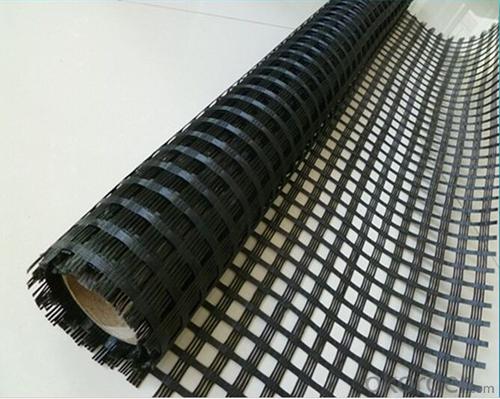

Reinforcement Polyester Geogrid :

(Warp Knitted Polyester Geogrid) :

Size | PET30/30--PET400/400; PET40/30--PET600/30 |

Price:FOB QINGDAO PORT | USD 0.3/Sq.m -- 5.0/Sq.m (LARGER QUANTITY WITH NICE PRICE) |

Packing in Roll

|

Roll width 3.95 Meter, 168 rolls in one 40HC Container.

|

Tensile strength at break | 30kn~600kn |

Stretching ratio | 13% |

Grid size | 12.7*12.7mm, 25.4*25.4mm, 50.8*50.8mm |

Mesh size | 9*9mm, 20*20mm, 35*35mm |

Roll width | 1.5m, 2m,3m,3.95m,5.8m |

Roll length | 50m, 100m |

Coating | PVC |

40HC container: | about 20000 Sq.m --50000 Sq.m |

Customize: | You can get more than what you pay for. Min 10000Sq.m |

Place of Origin | SHANDONG DAGENG, TAIAN CITY, SHANDONG, CHINA. |

Certificate | ISO ,CE |

1. Product introduction:

High strength polyester filament warp knitting geogrid select high strength synthetic fiber as raw material,adopt warp knitting oriented structure,and no curving between latitude and longitude fiber,use high strength filament on the intersection point to form firm bonding point,and fully perform the mechanical property.

2.Product features:

High strength polyester filament warp knitting geogrid possesses the characters of high intensity high module low creep deformation anti-aging anti-embrittlement high tensile strength big anti-peel strength strong binding force with soil and crushed stone and pre-design property and so on.

3. Application range:

1).Enhancement of soft roadbed of each kind of high grade road and railway,isolate different base material

2).Strengthen and stable river and slope of embankment.

3).Strengthen and stable each kind of base.

4).Strengthen the bridge and road surface.

FAQ

1. Can you send samples to us ?

Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

2. What’s your Payment term ?

T/T , L/C , Western Union,Paypal ...

3. What’s your delivery method ?

By sea , By train , etc

4. What's your MOQ quantity ?

MOQ is one 20'container , the quantity could be negotiable

- Q: Are geogrids suitable for use in soil reinforcement for pipeline crossings?

- Yes, geogrids are suitable for use in soil reinforcement for pipeline crossings. They provide excellent tensile strength and stability to the soil, helping to distribute loads and prevent soil movement or settlement. Geogrids are specifically designed to enhance soil performance and can effectively reinforce the soil around pipelines, ensuring their stability and longevity.

- Q: What is the typical geogrid roll thickness for specific applications?

- The typical geogrid roll thickness for specific applications can vary depending on the specific project requirements and the type of geogrid being used. However, in general, geogrid roll thicknesses range from 0.5 mm to 3 mm.

- Q: Can geogrids be used in reinforcement of embankments over soft soils?

- Yes, geogrids can be used in the reinforcement of embankments over soft soils. Geogrids are commonly used in civil engineering to provide stability and strength to soil structures, including embankments. By distributing the load and reducing lateral movement, geogrids can effectively reinforce embankments over soft soils, preventing slope failure and improving overall stability.

- Q: Can geogrids be used in bridge abutment construction?

- Yes, geogrids can be used in bridge abutment construction. Geogrids are commonly used to reinforce soil and provide stability in various civil engineering applications, including bridge abutments. They help distribute loads and improve the overall performance and longevity of the structure.

- Q: How do geogrids improve the stability of steep slopes?

- Geogrids improve the stability of steep slopes by providing reinforcement and preventing soil erosion. They are placed within the soil layers, creating a strong interlocking network that increases the shear strength and resistance to sliding. Additionally, geogrids distribute the load over a larger area, reducing the stress on the soil and preventing slope failures.

- Q: GDZ150 type one-way steel plastic welding geogrid D in the construction of the roadbed is horizontal paving also vertical spread?

- Of course it is perpendicular to the direction of the route

- Q: Are there any design guidelines for using geogrids in reinforcement applications?

- Yes, there are design guidelines available for using geogrids in reinforcement applications. These guidelines provide recommendations for selecting the appropriate geogrid type, determining the required strength and stiffness properties, and specifying the proper installation methods. The guidelines also outline factors such as soil characteristics, loading conditions, and project requirements that need to be considered in the design process. Adhering to these guidelines ensures the effective and efficient use of geogrids in reinforcement applications.

- Q: Specifications and parameters of Geotextiles

- Product specification is between SNG100-SNG1500. Width is 1-8m, long 50-100m (or according to customer requirements to produce)

- Q: What are the design considerations for geogrids in mechanically stabilized earth walls?

- The design considerations for geogrids in mechanically stabilized earth walls include factors such as the strength and stiffness of the geogrid material, the type and condition of the soil being stabilized, the required wall height and slope, the anticipated load and stability requirements, and the potential for differential settlement. Other considerations include the installation and construction methods, the compatibility of the geogrid with other wall components, and any potential environmental impacts. Overall, the design of geogrids in mechanically stabilized earth walls needs to ensure adequate stability, durability, and long-term performance of the structure.

- Q: How to determine geogrid reinforcement or crack resistance

- The old asphalt roadbed, will appear two different mutations in the direction of force wheel edge, a vertical load is the downward force of a horizontal tensile stress, long-term effect, and the influence of temperature and humidity, it is prone to fatigue cracking and subsidence layer to asphalt and asphalt overlay layer, caused by roadbed disease. According to the old asphalt roadbed fatigue cracking stress analysis by the line, in the asphalt layer and between concrete rigid base layer paving surface coating modified asphalt and self adhesive pressure sensitive adhesive of glass fiber geogrid in asphalt overlay and rigid concrete layer to form a good buffer zone, effective release of two mutations, prevent crack disease.

Send your message to us

Geocells Market - PVC Coated Polyester Geogrid Warp Knitting for Railway

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords