Geogrids for Roads - Warp Knitting Woven Polyester Geogrid with Bitumen/PVC Coated for Roadbed/Railway/Airport etc

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 12000 Square Meters Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Warp Knitting Woven Polyester Geogrid with Bitumen/PVC coated for Roadbed/Railway/Airport etc

1. Specifications for Warp Knitting Woven Polyester Geogrid with Bitumen/PVC coated for Roadbed/Railway/Airport etc

1).Strength: 20x20kn/m--600x600kn/m, such as :60/30, 60/60, 80/30, 120/30, 150/30, 200/30 etc.

2).Polyester Geogrid coated with PVC, Bitumen, SBR

3).Elongation:10% and 13%

4).Width: 1--6m

5).Packing:50m or100m/roll,

6).PE film outside, plstic tube inside.also can be made according clinet's need.

2. Application for Warp Knitting Woven Polyester Geogrid with Bitumen/PVC coated for Roadbed/Railway/Airport etc

1)Roadbed reinforcement of road and railway, crack prevention, increase of roadbed strength;

2)Reinforcement and stabilization of riverside, embankment and side slope;

3)Dyke reinforcement on soft ground for stress evenness, sedimentation adjustment, increase of stability and loading capacity of fundus;

4)Reinforcement of the surface of road and bridge

3. Technical Data for Warp Knitting Woven Polyester Geogrid with Bitumen/PVC coated for Roadbed/Railway/Airport etc

Product No. | Stretching ratio(%) | Grid(mm) | Width(mm) | ||

Vertical | Horizontal | ||||

PET20-20 | 13 | 20 | 20 | 12.7x12.7 25.4x25.4 | ±5 |

PET30-30 | 13 | 30 | 30 | 12.7x12.7 25.4x25.4 | ±5 |

PET40-40 | 13 | 40 | 40 | 12.7x12.7 25.4x25.4 | ±5 |

PET50-50 | 13 | 50 | 50 | 12.7x12.7 25.4x25.4 | ±5 |

PET80-80 | 13 | 80 | 80 | 12.7x12.7 25.4x25.4 | ±5 |

PET100-100 | 13 | 100 | 100 | 12.7x12.7 25.4x25.4 | ±5 |

PET120-120 | 13 | 120 | 120 | 12.7x12.7 25.4x25.4 | |

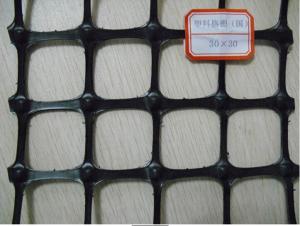

4. Some Photos for Warp Knitting Woven Polyester Geogrid with Bitumen/PVC coated for Roadbed/Railway/Airport etc

- Q: Longitudinal and transverse tensile strength more than 60kn/m which has several geogrid

- Glass fiber, polyester, plastic steel, PP, single and double, have 60 specifications.

- Q: What is the typical weight of a geogrid roll?

- The typical weight of a geogrid roll can vary depending on its size and material, but it typically ranges from 50 to 100 pounds.

- Q: What is the distance between the waterproof plate and the top of the tunnel? What are the relevant provisions of this specification?

- Some of the design drawings, the specification seems to be unable to find, which is related to the location of longitudinal flexible drainage pipe

- Q: How do geogrids improve the performance of retaining walls?

- Geogrids improve the performance of retaining walls by providing reinforcement and stability. They are typically made of high-strength materials and are installed within the soil mass behind the wall. These grids distribute the loads exerted on the wall more evenly, reducing the pressure on the wall itself. This reinforcement prevents excessive movement, soil erosion, and potential wall failure. Additionally, geogrids enhance the overall strength and durability of the retaining structure, allowing for the construction of taller and more efficient walls.

- Q: How do geogrids improve the performance of reinforced soil slopes in expansive soils?

- Geogrids improve the performance of reinforced soil slopes in expansive soils by providing additional reinforcement and stability. They help distribute the load and reduce the potential for slope failure by enhancing the tensile strength of the soil. Geogrids also control the lateral movement and prevent the soil from expanding and contracting, thus minimizing the risk of slope movement and erosion.

- Q: Geogrid nailed pictures and size

- U studs for the geogrid? You are ready to do the sale of finished products, or on the site directly on the grid?

- Q: How do geogrids help in the construction of embankments?

- Geogrids help in the construction of embankments by providing reinforcement and stability to the soil. They are placed within the embankment layers, acting as a support system that distributes the load more evenly and prevents soil erosion. This reinforcement enhances the embankment's strength, durability, and overall structural integrity.

- Q: How do geogrids help in reducing the risk of foundation settlement?

- Geogrids help in reducing the risk of foundation settlement by providing reinforcement and stability to the soil. They distribute the load from the foundation evenly, preventing excessive settlement or shifting of the soil. This helps to maintain the structural integrity of the foundation and minimize the potential for settlement-related damage.

- Q: Geogrid test items: what is the point of the joint point of penetration

- The conventional test items of geogrid are tensile strength, elongation, and welding point peeling force.

- Q: Do geogrids require any maintenance?

- Yes, geogrids generally do not require any maintenance once they are properly installed. They are designed to be durable and resistant to environmental factors, reducing the need for regular maintenance.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Geogrids for Roads - Warp Knitting Woven Polyester Geogrid with Bitumen/PVC Coated for Roadbed/Railway/Airport etc

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 12000 Square Meters Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords