GB Standard Steel H Beam 440-500mm with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Standard Steel H Beam 440-500mm with High Quality For Sale:

1. Standard: GB Standard

2. Grade: Q235

3. Length: 12m

Size and Mass:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 450*200*9.0 | 74.9 | 496*199*9.0 | 77.9 |

| 440*300*11.0 | 121 | 500*200*10.0 | 88.2 |

Usage & Applications of GB Standard Steel H Beam 440-500mm with High Quality For Sale:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of GB Standard Steel H Beam 440-500mm with High Quality for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truc4. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

4. Delivered by container or bulk vessel

Production flow of GB Standard Steel H Beam 440-500mm with High Quality For Sale:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

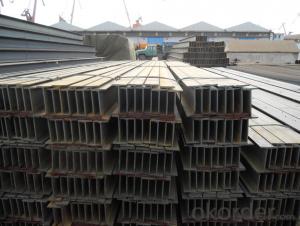

Images of GB Standard Steel H Beam 440-500mm with High Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: What are the different types of steel H-beams available?

- There exists a variety of steel H-beams, each possessing distinctive characteristics and applications. 1. Standard H-beams, widely used and versatile, come in various sizes and dimensions. They find application in the construction industry, providing structural support for buildings and bridges. 2. Wide flange beams, also known as W-beams, possess broader flanges compared to standard H-beams. This design enhances stability and support, rendering them suitable for heavy-duty applications like high-rise buildings, industrial structures, and platforms. 3. I-beams, while not technically H-beams, share a similar shape and are often grouped together. I-beams have a narrower profile, with a flange on one side and a web on the other. They are frequently employed in steel construction projects, including beams, columns, and joists. 4. Tapered H-beams feature a tapered shape, with diminishing flange and web thickness from top to bottom. They serve applications where weight reduction is crucial, such as aerospace industries or specific architectural designs. 5. Light H-beams are characterized by their lightweight design and find primary use in weight-sensitive applications like the automotive industry or lightweight structures. They offer a high strength-to-weight ratio and are available in various sizes. 6. Stainless steel H-beams are crafted from stainless steel, providing superior corrosion resistance and durability. They are commonly used in environments prone to moisture or chemical exposure, such as coastal areas or chemical processing plants. It is worth noting that the availability of these steel H-beam types may vary depending on the supplier or manufacturer. Therefore, it is advisable to consult a steel supplier or structural engineer to determine the most suitable H-beam type for your specific application.

- Q: The difference and use of H type steel steel and steel.

- H steel is a new type of economical construction steel. H type steel cross section shape is reasonable in economy, good mechanical properties, rolling each point on the extended section is uniform, small internal stress, compared with the ordinary beam, a section modulus, light weight, saving advantages of metal, can make the building structure to reduce 30-40%; and because of its inner and outer legs parallel leg end is right, assembled into components, welding, riveting work can save up to 25%. Often used in large capacity requirements, large cross section stability, such as buildings, high-rise buildings, as well as bridges, ships, lifting transport machinery, equipment foundation, support, foundation piles.

- Q: What are the common transportation methods for steel H-beams?

- The common transportation methods for steel H-beams include trucking, rail transportation, and sea freight. Trucking is often used for short to medium distance transportation of H-beams. Flatbed trucks with special equipment, such as cranes or forklifts, are typically utilized to load and unload the H-beams. This method provides flexibility and efficiency, as it allows for door-to-door delivery to construction sites or warehouses. Rail transportation is another common method for transporting steel H-beams. It is particularly suitable for long-distance shipments or transportation between regions. H-beams can be loaded onto flat railcars or in containers specially designed for steel products. Rail transportation is known for its large cargo capacity and cost-effectiveness for bulk shipments. For international shipments, sea freight is often used to transport steel H-beams. The H-beams are typically loaded into shipping containers or onto flat rack containers, which are specifically designed for oversized cargo. This method allows for efficient loading and unloading at ports and provides a cost-effective solution for long-distance transportation. The choice of transportation method for steel H-beams depends on various factors such as distance, cost, delivery time, and the specific requirements of the customer. Transportation companies and logistics providers work closely with their clients to determine the most suitable method based on these factors and ensure the safe and timely delivery of steel H-beams to their destination.

- Q: What are the limitations of steel H-beams?

- There are several limitations to steel H-beams. Firstly, their weight can be a significant drawback, making them difficult to handle and transport. Additionally, steel H-beams may not be suitable for certain applications where lightweight materials are required. Moreover, steel H-beams are prone to corrosion, especially in humid or corrosive environments, which can weaken their structural integrity over time. This necessitates regular maintenance and protective coatings to prevent deterioration. Another limitation is their limited flexibility in terms of design and shape. Steel H-beams are typically available in standard sizes and configurations, which may not always meet specific project requirements. Customization options can be limited and expensive. Finally, steel H-beams can be costlier compared to alternative materials, especially for smaller-scale projects. The high production and transportation costs associated with steel can make it less economical. Overall, while steel H-beams possess numerous advantages, it is crucial to consider these limitations to determine their suitability for a particular construction project.

- Q: Can steel H-beams be used for agricultural structures?

- Yes, steel H-beams can be used for agricultural structures. Steel H-beams offer several advantages for agricultural buildings. Firstly, they are incredibly strong and durable, able to withstand heavy loads and harsh weather conditions. This makes them ideal for supporting the weight of roofs, walls, and other structural components in agricultural buildings. Additionally, steel H-beams are versatile and can be easily customized to suit the specific requirements of agricultural structures. They can be cut to different sizes and lengths, allowing for flexibility in design and construction. This flexibility also makes them suitable for various types of agricultural buildings, such as barns, storage facilities, and livestock shelters. Moreover, steel H-beams are resistant to pests, rot, and decay, which can be common issues in agricultural environments. This ensures the longevity and reliability of the structures, minimizing the need for frequent repairs or replacements. Furthermore, steel H-beams are fire-resistant, offering an added layer of safety for agricultural buildings. This can be particularly important in areas where fire hazards are a concern. Finally, steel H-beams are cost-effective in the long run. Although they may have a higher upfront cost compared to other building materials, their durability and low maintenance requirements make them a cost-efficient choice over time. Overall, steel H-beams are a suitable and practical option for agricultural structures due to their strength, versatility, durability, resistance to pests and fire, and cost-effectiveness.

- Q: How do steel H-beams perform in snow-prone areas?

- Steel H-beams perform well in snow-prone areas due to their high strength and load-bearing capacity. The structural integrity of H-beams allows them to withstand heavy snow loads without significant deflection or failure. Additionally, the smooth surface of steel beams prevents snow accumulation, reducing the risk of roof collapse. Overall, steel H-beams are a reliable choice for snow-prone areas, ensuring safety and durability in challenging winter conditions.

- Q: What are the advantages of using steel H-beams over other types of beams?

- There are several advantages of using steel H-beams over other types of beams. Firstly, steel H-beams offer superior strength and load-bearing capacity, making them suitable for heavy-duty construction projects. Additionally, their shape provides better structural support, allowing for longer spans and reducing the need for additional supporting columns or walls. Steel H-beams also have a high resistance to bending and twisting, ensuring structural stability and durability. Moreover, they are cost-effective due to their availability, ease of fabrication, and recyclability. Lastly, steel H-beams provide design flexibility, enabling architects and engineers to create diverse and innovative structures.

- Q: What are the guidelines for handling and installing steel H-beams?

- The guidelines for handling and installing steel H-beams include ensuring proper lifting techniques are used, using appropriate lifting equipment with adequate capacity, properly securing the beams during transport, maintaining a level and stable surface during installation, aligning and supporting the beams correctly, following the manufacturer's instructions and specifications, and conducting regular inspections for any signs of damage or defects. Additionally, it is important to adhere to relevant safety regulations and guidelines, and consult with a qualified professional or engineer if needed.

- Q: Can steel H-beams be used for pedestrian walkways?

- Yes, steel H-beams can be used for pedestrian walkways. Steel H-beams are commonly used in construction due to their strength and durability. They provide a sturdy support system that can withstand heavy loads and ensure the safety of pedestrians. Additionally, steel H-beams can be designed to meet specific requirements such as length, width, and height, making them versatile for various walkway designs. They are also resistant to weather conditions and require minimal maintenance, making them an ideal choice for pedestrian walkways in both indoor and outdoor settings.

- Q: How do Steel H-Beams contribute to the overall occupant productivity of a building?

- Steel H-Beams contribute to the overall occupant productivity of a building by providing structural support and enhancing the stability of the structure. These beams are known for their strength and durability, which allows for larger open spaces and flexible floor layouts. This leads to a more efficient use of space, allowing occupants to have more room for their work activities. Additionally, steel H-Beams are fire-resistant and can withstand extreme weather conditions, ensuring the safety and comfort of occupants. Overall, the use of steel H-Beams in a building helps create a conducive environment for increased occupant productivity.

Send your message to us

GB Standard Steel H Beam 440-500mm with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords