GB Standard Steel H Beam 428mm-498mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Standard Steel H Beam 428mm-498mm with Good Quality:

1. Standard: GB Standard

2. Grade: Q235

3. Length: 12m

Size and Mass:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 428*407*20.0 | 283 | 498*432*45.0 | 605 |

| 458*417*30.0 | 415 | 446*199*8.0 | 65.1 |

Usage & Applications ofGB Standard Steel H Beam 428mm-498mm with Good Quality:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of GB Standard Steel H Beam 428mm-498mm with Good Quality for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truc4. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

4. Delivered by container or bulk vessel

Production flow of GB Standard Steel H Beam 428mm-498mm with Good Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

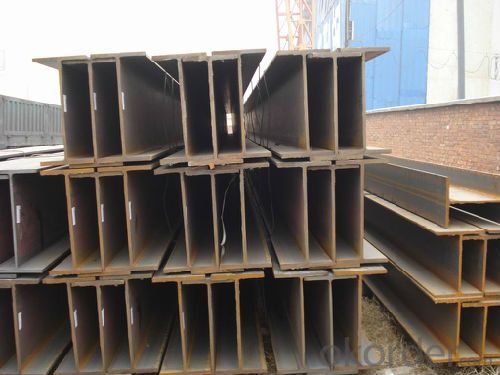

Images of GB Standard Steel H Beam 428mm-498mm with Good Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel H-beams be used in mezzanine or elevated flooring systems?

- Yes, steel H-beams can be used in mezzanine or elevated flooring systems. Steel H-beams are often used in construction due to their high strength and load-bearing capacity. They provide structural support and stability, making them suitable for creating elevated flooring systems such as mezzanines. The H shape of the beam helps distribute the weight evenly, allowing for larger spans and increased floor space. Additionally, steel H-beams can be easily connected and integrated into the overall structure, making them a popular choice for mezzanine and elevated flooring systems.

- Q: How do steel H-beams perform in extreme weather conditions such as hurricanes or cyclones?

- Steel H-beams are renowned for their exceptional strength and durability, which has made them a popular option for various construction applications, including in areas susceptible to severe weather conditions like hurricanes or cyclones. Steel H-beams have proven to be highly dependable when it comes to withstanding the forces exerted by these weather events. The distinctive structural design of H-beams, featuring flanges and a web, allows for the even distribution of loads along their length, making them resistant to bending or buckling. This structural integrity enables H-beams to endure the powerful winds and forces generated by hurricanes or cyclones. During extreme weather conditions like hurricanes, wind speeds can reach incredibly high velocities. The aerodynamic design of H-beams, characterized by their streamlined shape and minimal surface area, helps reduce wind resistance. This significantly reduces the likelihood of the beams being blown away or damaged during the storm. Furthermore, steel H-beams possess excellent corrosion resistance properties. They are often galvanized or coated with protective coatings, which prevent rust or deterioration caused by moisture, a common occurrence during hurricanes or cyclones. This ensures that the structural integrity of the beams remains intact even after prolonged exposure to extreme weather conditions. In addition, steel H-beams have a high load-bearing capacity, allowing them to support heavy loads such as roofs, walls, or floors. This strength is particularly vital during hurricanes or cyclones, where the beams must withstand not only the wind forces but also the weight of debris or falling objects. In conclusion, steel H-beams are engineered to perform exceptionally well in extreme weather conditions such as hurricanes or cyclones. Their strength, durability, resistance to bending and buckling, corrosion resistance, and high load-bearing capacity make them a reliable choice for construction in areas prone to such weather events.

- Q: What is a steel H-beam?

- A steel H-beam, also known as H-section or I-section, is a structural beam made of steel with a shape resembling the letter "H". It is widely used in construction and civil engineering projects due to its high strength and versatility. The H-beam is designed to distribute the weight or load evenly across its horizontal flanges, which are connected by a vertical web. This design provides excellent load-bearing capabilities and allows for longer spans and greater stability in structures. H-beams are commonly used in buildings, bridges, highways, and other infrastructure projects to support heavy loads and resist bending or twisting forces. The steel H-beam is manufactured through a process of hot rolling or welding, and it is available in various sizes and dimensions to suit different applications.

- Q: What is the lifespan of steel H-beams?

- Several factors can influence the lifespan of steel H-beams, including the quality of the steel, usage conditions, and maintenance levels. Generally, steel H-beams are designed for durability and can be used in various structural applications. If manufactured and maintained correctly, steel H-beams can last for several decades or even longer. Steel's high strength and structural integrity enable it to endure heavy loads, harsh weather conditions, and other external factors that may degrade the material over time. However, it is crucial to consider that several factors can contribute to the deterioration of steel H-beams. These factors include exposure to corrosive elements like moisture, chemicals, and saltwater, as well as structural overload, excessive vibrations, and improper installation or handling. Regular inspections and maintenance play a significant role in identifying signs of corrosion, fatigue, or structural damage that could affect the beams' lifespan. In conclusion, the lifespan of steel H-beams can be extensive if they are manufactured properly, maintained correctly, and used within their design limitations. By implementing appropriate maintenance practices and safeguarding the beams from adverse conditions, it is possible to significantly extend their lifespan.

- Q: Can Steel H-Beams be used in school or educational building construction?

- Yes, Steel H-Beams can be used in school or educational building construction. Steel H-Beams are commonly used in construction projects due to their strength and durability. They provide reliable structural support for large spans and heavy loads, making them suitable for constructing educational facilities such as schools and universities. These beams can be used for various purposes, including supporting the roof, creating open floor plans, or constructing large-scale structures like gymnasiums or auditoriums. Additionally, Steel H-Beams can be easily fabricated and installed, making them a cost-effective and efficient choice for educational building construction.

- Q: Can steel H-beams be customized to specific lengths?

- Yes, steel H-beams can be customized to specific lengths. Steel H-beams are commonly used in construction and are available in various standard lengths. However, if the standard lengths do not meet the specific requirements of a project, they can be customized to the desired length. This can be done by cutting the beams to the required length and then welding or bolting the ends together to create the desired length. Customizing the length of steel H-beams allows for more flexibility in construction projects and ensures that the beams fit perfectly for a specific application.

- Q: What are the advantages of using steel H-beams over other types of beams?

- There are several advantages of using steel H-beams over other types of beams. Firstly, steel H-beams offer superior strength and load-bearing capacity, making them suitable for heavy-duty construction projects. Additionally, their shape provides better structural support, allowing for longer spans and reducing the need for additional supporting columns or walls. Steel H-beams also have a high resistance to bending and twisting, ensuring structural stability and durability. Moreover, they are cost-effective due to their availability, ease of fabrication, and recyclability. Lastly, steel H-beams provide design flexibility, enabling architects and engineers to create diverse and innovative structures.

- Q: Can steel H-beams be used for soundproofing walls?

- No, steel H-beams are not an effective material for soundproofing walls.

- Q: What is the purpose of using steel H-beams in construction?

- The purpose of using steel H-beams in construction is to provide structural support and stability to buildings and other structures. The H-shape design of the beam allows for better load distribution and resistance to bending and twisting forces, making it ideal for withstanding heavy loads and maintaining the integrity of the structure.

- Q: H Elastic modulus of section steel

- Generally speaking, elasticity exerts an external effect on an elastic body, and it changes in shape (called strain)

Send your message to us

GB Standard Steel H Beam 428mm-498mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords