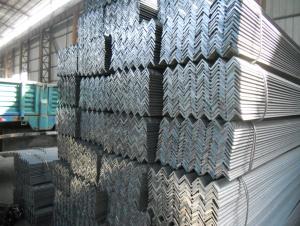

Steel Angle Bar-GB Standard

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request.

2. Length: 6m, 9m, 12m.

3. Sizes:

| Size(mm) | Mass(Kg/m) | Size(mm) | Mass(Kg/m) |

| 120*120*10 | 18.055 | 150*150*10 | 22.765 |

| 125*125*8 | 15.504 | 150*150*12 | 27.13 |

| 125*125*10 | 19.133 | | |

Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C.

Material details:

Alloy No | Grade | Element (%) | | ||||

C | Mn | S | P | Si | | ||

| | |||||||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | | ||||

Thickness (mm) | | ||||||

≤16 | >16--40 | >40--60 | >60--100 | | |||

≥ | | ||||||

|

|

|

|

|

| | |

Q235 | B | 235 | 225 | 215 | 205 | | |

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | | |||

Thickness (mm) | | ||||||

| ≤16 | >16--40 | >40--60 | >60--100 | | ||

≥ | | ||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel angles be used for modular furniture or fixtures?

- Yes, steel angles can definitely be used for modular furniture or fixtures. Steel angles are versatile and strong structural components that can be easily incorporated into modular furniture designs. They provide stability and support to the overall structure, making them ideal for creating modular pieces that are sturdy and durable. Steel angles can be used as corner brackets or supports for shelves, cabinets, or other modular components. They can be easily cut, welded, or drilled to fit specific design requirements, allowing for flexibility in creating different configurations or sizes of modular furniture. Additionally, steel angles can be powder coated or painted in different colors to match the desired aesthetic of the furniture or fixtures. The use of steel angles in modular furniture or fixtures also ensures longevity, as they are resistant to wear and tear, corrosion, and impact. This makes them suitable for both indoor and outdoor applications. Moreover, steel angles are readily available and cost-effective, making them a practical choice for modular furniture or fixture manufacturing. In conclusion, steel angles are an excellent choice for creating modular furniture or fixtures due to their strength, versatility, and durability. They provide stability and support to the structure, can be easily customized, and offer long-lasting performance. Whether it is for residential or commercial use, steel angles can be utilized to create modular furniture or fixtures that are both functional and aesthetically pleasing.

- Q: What are the different corrosion protection methods for steel angles?

- There are several different corrosion protection methods available for steel angles, depending on the specific application and environmental conditions. Some of the most common methods include: 1. Galvanization: This involves coating the steel angles with a layer of zinc, which provides excellent corrosion resistance. The zinc layer acts as a sacrificial anode, corroding instead of the underlying steel. 2. Paint coatings: Applying a high-quality paint coating to the steel angles can provide effective corrosion protection. The paint acts as a barrier, preventing moisture and corrosive substances from reaching the steel surface. 3. Powder coating: Similar to paint coatings, powder coating involves applying a dry powder to the steel angles and then baking it to create a durable and corrosion-resistant finish. 4. Epoxy coatings: Epoxy coatings are commonly used for steel angles that will be exposed to harsh environments or aggressive chemicals. These coatings provide excellent adhesion and resistance to corrosion. 5. Cathodic protection: This method involves using a sacrificial anode or impressed current to protect the steel angles from corrosion. The anode corrodes instead of the steel, providing long-term protection. 6. Barrier coatings: Barrier coatings, such as polyethylene or PVC wraps, provide a physical barrier between the steel angles and the surrounding environment, preventing moisture and corrosive substances from reaching the surface. 7. Hot-dip galvanizing: In this method, the steel angles are immersed in a bath of molten zinc, creating a thick layer of zinc coating that offers excellent corrosion protection. It is important to consider the specific requirements of the application when choosing a corrosion protection method for steel angles. Factors such as the environment, expected service life, and budget should be taken into account to ensure the most suitable protection method is selected.

- Q: Are steel angles available in different alloys?

- Different alloys are available for steel angles, providing a wide range of options. Typically, steel angles are made from carbon steel, which is a versatile and common type of steel. However, specific applications may call for other alloys. For instance, stainless steel angles are made from an alloy containing chromium, offering increased resistance to corrosion. In addition, high-strength low-alloy (HSLA) steel angles combine carbon steel with small amounts of elements like manganese, phosphorus, or sulfur to enhance strength and durability. This variety of alloys allows for a diverse range of applications and properties to meet specific needs across various industries.

- Q: Can steel angles be used for support beams?

- Yes, steel angles can be used for support beams. Steel angles are commonly used in construction as structural elements due to their strength and durability. They provide excellent support and stability, making them suitable for various applications, including as support beams. Steel angles are often used to reinforce and support structures such as buildings, bridges, and platforms. They can be easily welded or bolted together to create a strong and stable framework. Steel angles come in different sizes and thicknesses, allowing for customization and adaptation to specific load-bearing requirements. Overall, steel angles are a reliable and commonly used option for support beams in construction projects.

- Q: What are the different types of connections for steel angles?

- There are several different types of connections for steel angles, including bolted connections, welded connections, and clip connections. Bolted connections involve using bolts and nuts to secure the angles together, while welded connections are created by melting the edges of the angles together. Clip connections use specially designed clips to hold the angles in place without the need for welding or bolting. Each type of connection has its own advantages and disadvantages, and the choice of connection method depends on factors such as the load-bearing requirements, ease of installation, and cost.

- Q: How do steel angles perform in high-pressure applications?

- Steel angles are widely used in high-pressure applications due to their excellent performance under extreme conditions. The structural design and composition of steel angles provide them with exceptional strength and durability, making them capable of withstanding high pressure without deformation or failure. The unique shape of steel angles, with their L-shaped cross-section, enhances their load-bearing capacity and resistance to bending. This makes them ideal for applications where high-pressure forces are exerted, such as in the construction of pressure vessels, pipelines, and hydraulic systems. Steel angles are typically manufactured from high-strength carbon steel, which possesses inherent toughness and resilience. This material composition enables steel angles to maintain their structural integrity even when subjected to the intense forces associated with high-pressure environments. Furthermore, the versatility of steel angles allows for customization and adaptation to specific needs. They can be fabricated in different sizes, thicknesses, and lengths to accommodate varying pressure requirements. This flexibility ensures that steel angles can be tailored to specific applications, further enhancing their performance in high-pressure scenarios. In addition to their mechanical properties, steel angles also exhibit excellent corrosion resistance. This is crucial in high-pressure applications, as the presence of corrosive substances can deteriorate the structural integrity of components. The inherent corrosion resistance of steel angles prevents degradation over time, ensuring their long-term reliability and performance. Overall, steel angles are highly reliable and effective in high-pressure applications. Their exceptional strength, versatility, and corrosion resistance make them a preferred choice in industries where pressure containment is critical. By utilizing steel angles, operators can trust that their systems will perform reliably and safely under extreme pressure conditions.

- Q: How do you calculate the bending stress in a steel angle?

- To calculate the bending stress in a steel angle, you need to understand the basics of bending moment and the moment of inertia of the angle. First, you will need to determine the bending moment acting on the steel angle. This can be done by considering the applied load or force and its distance from the point of rotation. The bending moment is calculated as the product of the applied load and the distance between the point of rotation and the line of action of the force. Next, you will need to determine the moment of inertia of the steel angle. The moment of inertia measures the resistance of an object to changes in its rotational motion. It depends on the shape and size of the object. In the case of a steel angle, the moment of inertia can be calculated using the appropriate formula for the specific cross-sectional shape of the angle. Once you have determined the bending moment and the moment of inertia, you can calculate the bending stress using the formula: Bending Stress = (Bending Moment * Distance from Neutral Axis) / Moment of Inertia The bending stress represents the internal resistance within the steel angle to the bending moment. It is typically expressed in units of force per unit area, such as pounds per square inch (psi) or newtons per square meter (Pa). It is important to note that the calculation of bending stress assumes that the steel angle behaves elastically, meaning it is not subjected to excessive deformation or permanent damage. If the applied bending moment exceeds the elastic limit of the steel angle, plastic deformation or failure may occur, and a different analysis method would be required.

- Q: What is the maximum allowable torsional stress for a steel angle?

- The maximum allowable torsional stress for a steel angle depends on several factors, including the specific grade of steel, the dimensions and shape of the angle, and the intended application. Steel angles are commonly used in structural applications, such as supporting beams and frames, and they are designed to withstand various types of stresses, including torsional stress. To determine the maximum allowable torsional stress for a steel angle, engineers typically refer to industry standards and codes, such as the American Institute of Steel Construction (AISC) Manual or the European standard EN 10056. These standards provide guidelines and formulas for calculating the maximum allowable torsional stress based on the properties of the steel angle, such as the cross-sectional area, moment of inertia, and modulus of elasticity. It is important to note that the maximum allowable torsional stress is usually specified as a percentage of the yield strength or ultimate tensile strength of the steel. This ensures that the angle can safely withstand torsional loads without undergoing permanent deformation or failure. In practical applications, engineers and designers must carefully analyze the specific requirements and loading conditions to determine the appropriate maximum allowable torsional stress for a steel angle. They consider factors such as the magnitude and direction of the applied torque, the angle's orientation, and any additional loads or constraints that may be present. Ultimately, the maximum allowable torsional stress for a steel angle is a critical parameter in ensuring the structural integrity and safety of a given design. Proper consideration of the steel's properties, industry standards, and specific application requirements is essential for making accurate calculations and selecting an appropriate steel angle that can effectively resist torsional stress.

- Q: Are steel angles resistant to impact or vibration?

- Steel angles are known for their high strength and durability, making them generally resistant to impact and vibration. However, the specific resistance to these forces would depend on various factors such as the thickness and quality of the steel, as well as the magnitude and frequency of the impact or vibration.

- Q: What are the common installation methods for steel angles?

- The common installation methods for steel angles include welding, bolting, and using adhesive.

Send your message to us

Steel Angle Bar-GB Standard

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords