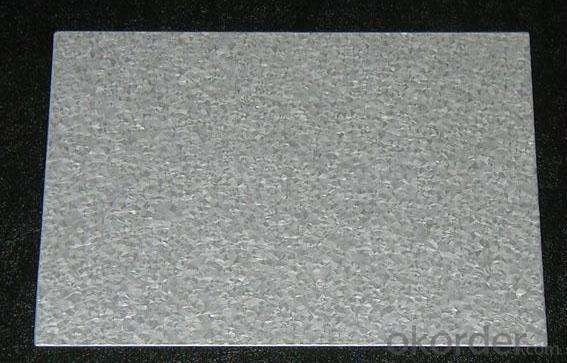

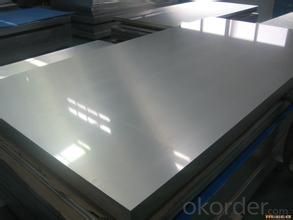

Gavalume steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Standard | GB/T14978, ASTM A792M, JIS G3321, EN10215, etc |

Grade | DX51D-AZ, DX53D-AZ, SGLCC, SS255-550, etc |

Thickness | 0.35-2.3mm |

Width | 600-1270mm |

Inner Diameter | 508mm |

AZ Coated | AZ 50-200 |

Coil Weight | 12Tons max |

Technology | hot dip aluminum and zinc |

Post-processing | Chromated, Anti-finger printed, Oiled, etc |

a.) Construction: roof, walls, garage, soundproof walls, pipes and combined house, etc.

b.) Car: muffler, exhaust pipe, wiper accessories, fuel tanks, truck boxes, etc.

c.) Appliance: refrigerator backplane, gas stove, air conditioner, microwave, LCD border CRT explosion-proof belt, LED backlight, electrical cabinets, etc.

d.) Farm: pigsty, henhouse, granary, greenhouse with pipes etc.

e.) Other: broken thermal insulation cover, heat exchanger, dryer, warm water device, etc.

- Q: Can steel sheets be recycled without losing their properties?

- Yes, steel sheets can be recycled without losing their properties. Steel is a highly recyclable material, and the recycling process does not significantly alter its properties, such as strength and durability. This allows for steel sheets to be recycled and reused multiple times without compromising their integrity.

- Q: How do steel sheets handle expansion and contraction?

- Due to its unique properties, steel sheets are capable of managing expansion and contraction in a predictable and controlled manner. Steel is renowned for its remarkable strength and durability, enabling it to endure the forces exerted during expansion and contraction without compromising its structural integrity. When steel sheets are exposed to high temperatures, such as those experienced during welding or in extreme environmental conditions, expansion occurs. This expansion is a result of the accelerated movement of steel molecules due to heat, leading to an increase in size. However, steel possesses a relatively low coefficient of thermal expansion, causing it to expand less compared to materials like concrete or wood. This property makes steel an advantageous choice for applications where dimensional stability is crucial. To effectively manage expansion, steel sheets are often designed with expansion joints or gaps that allow for movement. These joints can be found in structures such as bridges, buildings, or pipelines. They are strategically placed to accommodate the anticipated expansion and contraction of steel sheets without causing damage or deformation. Furthermore, the ability of steel to contract is equally significant. When exposed to lower temperatures, steel sheets shrink or contract. Although this contraction is typically less noticeable than expansion, it still needs to be taken into consideration in engineering designs. Fortunately, the contraction of steel is generally within acceptable limits and does not compromise the material's structural integrity. Overall, steel sheets are engineered to effectively handle expansion and contraction. The combination of a low coefficient of thermal expansion and the presence of expansion joints allows steel to accommodate temperature fluctuations without inducing significant stress or deformation. This makes steel a reliable and versatile material for numerous industries, including construction, manufacturing, and infrastructure.

- Q: Can steel sheets be used for signage or advertising displays?

- Yes, steel sheets can be used for signage or advertising displays. Steel is a durable and versatile material that can be cut, shaped, and painted to create eye-catching displays. It provides a sturdy base for signs and can withstand outdoor conditions.

- Q: 16 what is the hardness of manganese steel plates?

- Manganese steel is a kind of high strength abrasion resistant steel. It is mainly used to endure shock, extrusion, material wear and other bad working conditions. The form of failure is mainly wear and tear, partial fracture and deformation. The wear is divided into three types: the friction and wear between the contact surface of the metal component and movement; abrasive wear and erosion of flowing gas or liquid and metal contact wear caused by other metal or non-metal materials against the metal surface. The wear resistance of wear-resistant steel depends on the material itself, while the wear-resistant steel shows different wear resistance under different working conditions. Both the material itself and the working conditions can determine its wear resistance.

- Q: Can steel sheets be used for storage shelves?

- Yes, steel sheets can be used for storage shelves. Steel is a strong and durable material that can withstand heavy loads, making it suitable for storage shelving systems. Steel sheets can provide a sturdy platform to store items and can be easily customized to fit the desired dimensions and specifications.

- Q: Are steel sheets suitable for outdoor sculptures or artwork?

- Yes, steel sheets are suitable for outdoor sculptures or artwork. Steel is a durable and weather-resistant material that can withstand the elements, making it ideal for outdoor installations. Additionally, steel sheets offer flexibility in terms of shaping and forming, allowing artists to create intricate and unique designs for their sculptures or artwork.

- Q: Can steel sheets be used for electromagnetic shielding?

- Yes, steel sheets can be used for electromagnetic shielding.

- Q: What's the difference between a spray plate and a colored steel plate?

- Plastic sheet, first can choose the thickness and material on the plate, and then spray processing, and then processing the plastic powder color and quality can choose according to your requirements, general plastic plate from high-end to low-end can meet your requirements, if you need to own production will be cumbersome!

- Q: Are steel sheets suitable for structural applications?

- Yes, steel sheets are suitable for structural applications. Steel sheets are known for their high strength, durability, and ability to withstand heavy loads, making them an ideal choice for various structural applications such as bridges, buildings, and industrial structures.

- Q: Can steel sheets be used for manufacturing shipping containers?

- Indeed, the utilization of steel sheets in the production of shipping containers is possible. Steel, being a robust and durable material, offers exceptional structural resilience, rendering it an ideal choice for the construction of shipping containers. Typically, steel sheets are employed in fabricating the container's walls, roof, and floor, guaranteeing its ability to endure the demanding conditions of transportation and safeguard the goods contained within. Moreover, steel exhibits resistance to diverse weather conditions, corrosion, and pests, thereby establishing it as a trustworthy option for the manufacturing of shipping containers.

Send your message to us

Gavalume steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords