The corrugated sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The corrugated sheet is a high strength and durable steel, mostly used for a architectural decoration. We can produce profiled sheets of all kinds of types and colors. Since it adopts high strength steel sheet and the dimension is designed reasonably, the corrugated sheets are widely used on roofs and walls of various buildings, which can be easily installed, be flexible and changeable, unrestricted by no factor of the buildings.

Pressing steel panel with the clear line, and many colors for choice, suitable for any different building style materials, achieving satisfy effects;

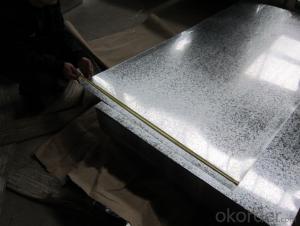

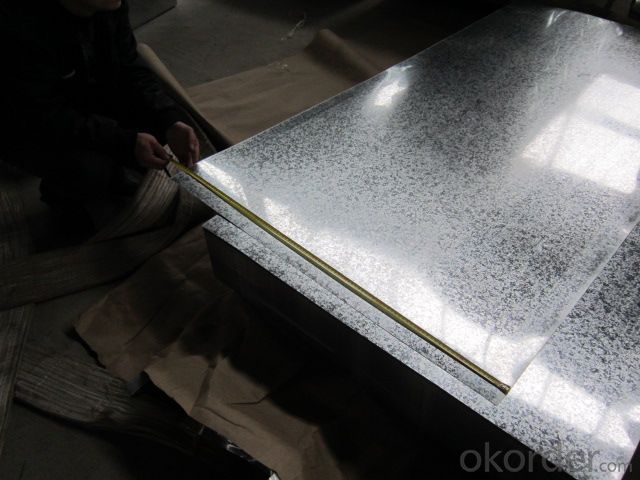

CORRUGATED PREPAINTED GALVANIZED STEEL SHEET

STEEL GRADE & STANDARD:JIS G3312 CGCC

ZINC COATING MASS:Z60(+/-10g)

TOP COATING THICKNESS & TYPE:5+10UM POLYESTER

TOP COATING COLOR:RAL9002

BACK COATING THICKNESS & TYPE:5UM EPOXY

BACK COATING COLOR:WHITE GREY

THICKNESS :0.2MM

WIDTH:900MM

LENGTH:2000MM

PACKAGE TYPE:PACKED WITH STEEL PALLET

BUNDLE WEIGHT:AROUND 3MT

SHAPE AS PER PICTURE & SAMPLE FROM BUYER

- Q: Can steel sheets be used for interior design purposes?

- Yes, steel sheets can be used for interior design purposes. Steel sheets have a sleek and modern appearance that can add an industrial or contemporary touch to any interior space. They are durable, long-lasting, and resistant to wear and tear, making them suitable for high-traffic areas. Steel sheets can be used in various ways in interior design, such as wall cladding, ceiling panels, room dividers, furniture, countertops, and backsplashes. They can be painted or coated in different finishes to match the desired aesthetic, and can also be shaped or perforated to create unique patterns or textures. Overall, steel sheets offer versatility, strength, and a visually appealing element to interior design projects.

- Q: Can steel sheets be used for insulation purposes?

- No, steel sheets cannot be used for insulation purposes as they conduct heat and electricity, rather than providing insulation against them.

- Q: What is the difference between a hot rolled and cold rolled galvanized steel sheet?

- The main difference between a hot rolled and cold rolled galvanized steel sheet is the process in which they are made. Hot rolled galvanized steel sheets are produced by rolling the steel at high temperatures, which results in a rougher surface and less precise dimensions. On the other hand, cold rolled galvanized steel sheets are processed at lower temperatures, allowing for a smoother surface finish and more precise dimensions. Additionally, the cold rolling process also tends to make the steel stronger and more durable.

- Q: What are the insulation properties of steel sheets?

- Steel sheets have relatively poor insulation properties compared to other materials commonly used for insulation, such as fiberglass or foam. This is because steel is a good conductor of heat and electricity. It has high thermal conductivity, meaning that it can easily transfer heat from one side to the other. Therefore, steel sheets are not effective in preventing heat transfer and are not typically used as insulation materials on their own. However, steel sheets can still provide some insulation benefits when used in combination with other insulating materials. For instance, steel sheets can be used as a protective layer or cladding to enhance the durability and fire resistance of insulation systems. They can also be used as a radiant barrier, reflecting heat away from the building and reducing heat gain in warm climates. In summary, while steel sheets themselves do not have great insulation properties, they can play a role in enhancing the overall insulation performance when combined with other insulating materials or used in specific applications like radiant barriers.

- Q: What material is steel plate against drilling?

- All high nickel, high tungsten, or both titanium (tungsten carbide and titanium carbide), cobalt, molybdenum, niobium and other elements of the steel can be drilled.

- Q: Can steel sheets be used for electrical motors?

- Indeed, electrical motors can utilize steel sheets. Due to its magnetic properties, steel is frequently employed in the construction of these motors. Specifically, the sheets of steel are typically utilized to form the motor's core, which is responsible for generating the essential magnetic field. With its high magnetic permeability, steel can effortlessly conduct and direct magnetic flux, rendering it an optimal material for this purpose. Moreover, steel is durable and capable of withstanding the elevated temperatures and mechanical pressures that electrical motors may encounter while in operation. Consequently, steel sheets are frequently selected as a dependable and economical choice for constructing electrical motors.

- Q: What is the maximum thickness of a steel sheet?

- The maximum thickness of a steel sheet can vary depending on various factors such as the type of steel, the manufacturing process, and the intended use. However, generally speaking, steel sheets can be manufactured up to a thickness of around 25 millimeters (1 inch) or even thicker in some cases. Thicker steel sheets are often used in heavy-duty applications such as construction, shipbuilding, and industrial machinery where strength and durability are crucial. It is important to consult with manufacturers or industry standards to determine the specific maximum thickness for a particular type of steel sheet.

- Q: What is the process of applying anti-corrosion treatments to steel sheets?

- The process of applying anti-corrosion treatments to steel sheets typically involves several steps. Firstly, the steel sheets are thoroughly cleaned and degreased to remove any dirt, oils, or contaminants. This is done using specialized cleaning agents and techniques such as solvent cleaning or alkaline cleaning. Once the sheets are clean, they may undergo a process called surface preparation or surface conditioning. This step involves roughening the surface of the steel to enhance the adhesion of the anti-corrosion treatment. Common methods used for surface preparation include sandblasting, shot blasting, or acid etching. After surface preparation, the steel sheets are ready to be coated with the anti-corrosion treatment. There are various types of treatments available, such as metallic coatings, organic coatings, or conversion coatings. Metallic coatings, such as galvanizing or electroplating, involve applying a layer of metal onto the surface of the steel sheets to provide a protective barrier against corrosion. Organic coatings, such as paint or powder coatings, are applied as a liquid or powder and form a protective film over the steel surface. Conversion coatings involve a chemical reaction with the steel surface to create a protective layer. The application of the anti-corrosion treatment can be done through several methods, including spraying, dipping, or brushing. The specific method used may depend on factors such as the type of treatment, the size of the steel sheets, and the desired finish. After the treatment is applied, the steel sheets may undergo a curing or drying process to ensure the treatment adheres properly and forms a durable protective layer. This can involve air drying, baking in ovens, or using heat lamps. Overall, the process of applying anti-corrosion treatments to steel sheets involves cleaning, surface preparation, coating application, and curing. These steps help to protect the steel from corrosion and extend its lifespan.

- Q: How thick are steel sheets available?

- A wide variety of thicknesses can be found for steel sheets, catering to the specific needs of each application. Steel sheets commonly come in thicknesses ranging from 0.5mm (or 0.020 inches) up to several inches. Gauge is typically used to measure the thickness of steel sheets, with lower gauge numbers indicating thicker sheets. Nevertheless, it's worth mentioning that the availability of steel sheets in particular thicknesses might differ depending on the supplier and the type of steel employed.

- Q: How to pass through steel at water stop steel plate?

- The steel bar cannot pass through the water stopping steel plate, and this should be taken into consideration when arranging the water stop steel plate.Therefore, the water stop steel plate is usually arranged at the end of the plate or wall, but can not be arranged at the edge of the beam column, otherwise the stirrup is interrupted.

Send your message to us

The corrugated sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords