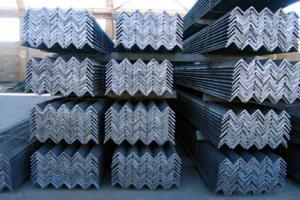

GALVANIZED STEEL ENGLE BAR EQUAL STEEL BAR UNEQUAL STEEL BAR JIS GB

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Galvanized Angle Steel

Galvanized Angle Steel Zinc Thickness: 15--80μ

Hot Galvanized Angle Steel ss400

Sizes: 25*25~250*250mm

Grades: SS400,SS540,A36

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m

3. Sizes:

HOT DIPPED GALVANIZED EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M |

30 | 30 | 2.5---4.0 | 6M |

38 | 38 | 2.5 | 6M |

38 | 38 | 3.0---5.0 | 6M |

40 | 40 | 3.0---6.0 | 6M |

50 | 50 | 3 | 6M |

50 | 50 | 3.7---6.0 | 6M |

60 | 60 | 5.0---6.0 | 6M |

63 | 63 | 6.0---8.0 | 6M |

65 | 65 | 5.0---8.0 | 6M |

70 | 70 | 6.0---7.0 | 6M |

75 | 75 | 5.0---10.0 | 6M |

80 | 80 | 6.0---10.0 | 6M |

90 | 90 | 6.0---10.0 | 6M |

100 | 100 | 6.0---12.0 | 6M |

120 | 120 | 8.0-12.0 | 6M |

125 | 125 | 8.0---12.0 | 6M |

130 | 130 | 9.0-12.0 | 6M |

140 | 140 | 10.0-16.0 | 6M |

150 | 150 | 10---15 | 6M |

160 | 160 | 10---16 | 6M |

180 | 180 | 12---18 | 6M |

200 | 200 | 14---20 | 6M |

5. PROCESS: HOT-DIP GALVANIZATION of Galvanized Angle Steel

Hot-dip galvanization is a form of galvanization. It is the process of coating iron, steel or aluminium with a layer of zinc by immersing the metal in a bath of molten zinc at a temperature of around 860 °F (460 °C). When exposed to the atmosphere, the pure zinc (Zn) reacts with oxygen (O2) to form zinc oxide (ZnO), which further reacts with carbon dioxide (CO2) to form zinc carbonate (ZnCO3), a usually dull grey, fairly strong material that stops further corrosion in many circumstances, protecting the steel below from the elements. Galvanized steel is widely used in applications where corrosion resistance is needed, and can be identified by the crystallization patterning on the surface (often called a "spangle").

Usage & Applications of Galvanized Angle Steel

Galvanized steel can be welded; however, one must exercise caution around the resulting zinc fumes. Galvanized steel is suitable for high-temperature applications of up to 392 °F (200 °C). The use of galvanized steel at temperatures above this will result in peeling of the zinc at the inter metallic layer. Electrogalvanized sheet steel is often used in automotive manufacturing to enhance the corrosion performance of exterior body panels; this is, however, a completely different process which tends to achieve lower coating thicknesses of zinc.

Like all other corrosion protection systems, galvanizing protects steel by acting as a barrier between steel and the atmosphere. However, zinc is a more electronegative metal in comparison to steel, this is a unique characteristic for galvanizing which means that when a galvanized coating is damaged and steel is exposed to the atmosphere, zinc can continue to protect steel (often within an annulus of 5 mm above which electron transfer rate decreases)..

Packaging & Delivery of Galvanized Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

- Q: What are the common grades of stainless steel angles?

- The market offers commonly used and readily available stainless steel angles in grades 304 and 316. Grade 304 stainless steel angles are highly regarded for their exceptional corrosion resistance, strong durability, and favorable formability. They find extensive application in industries such as food and beverage, chemical processing, and outdoor structures, where exposure to corrosive environments is a concern. On the other hand, grade 316 stainless steel angles provide even superior resistance to corrosion, particularly against pitting and crevice corrosion. This makes them ideal for marine environments and situations involving acidic or chloride-rich conditions. Both grades possess versatility, allowing for easy welding, fabrication, and machining to fulfill specific project requirements.

- Q: How do you calculate the moment of resistance for a stainless steel angle?

- To calculate the moment of resistance for a stainless steel angle, you need to consider the properties of the angle section and the applied loads. The moment of resistance is a measure of the section's ability to resist bending or twisting forces. First, you need to determine the geometrical properties of the stainless steel angle, such as the cross-sectional area, moment of inertia, and the distance from the centroid to the extreme fibers. These properties can be obtained from the manufacturer's specifications or by measuring the angle section directly. Next, you need to determine the maximum allowable stress for the stainless steel material. This value can be obtained from material specifications or design codes. It is important to consider the appropriate stress value based on the type of loading (tension, compression, or bending) and the safety factor required for the application. Once you have the geometrical properties and allowable stress, you can calculate the moment of resistance using the following formula: Moment of Resistance = Allowable Stress x Moment of Inertia / Distance to Extreme Fibers By substituting the values into the formula, you can calculate the moment of resistance for the stainless steel angle. This value represents the maximum bending moment the angle can withstand without failure. It is important to note that this calculation assumes the stainless steel angle behaves elastically and does not take into account any plastic deformation or failure modes. Additionally, if the angle is subjected to combined loading or complex loading conditions, more advanced analysis methods may be required to accurately determine the moment of resistance.

- Q: Can stainless steel angles be used for playground equipment?

- Yes, stainless steel angles can be used for playground equipment. Stainless steel is a durable and corrosion-resistant material, making it ideal for outdoor applications such as playground equipment. It is able to withstand harsh weather conditions and heavy use, ensuring the safety and longevity of the equipment. Stainless steel angles can be used to construct various components of playground equipment, such as frames, supports, and ramps, providing stability and strength. Additionally, stainless steel has a sleek and modern appearance, enhancing the aesthetic appeal of the playground.

- Q: What are the different surface treatments available for stainless steel angles?

- Stainless steel angles offer a range of surface treatments, each with its own advantages and characteristics. 1. Polishing: By smoothing out any roughness or flaws, polishing gives stainless steel angles a sleek and glossy finish. This treatment is ideal for applications where visual appeal is important, like architectural or decorative projects. 2. Brushing: Using abrasive materials or brushes, brushing creates a textured pattern on the surface of stainless steel angles. This treatment adds a visually captivating and durable touch, often favored in industrial or modern designs. 3. Electropolishing: Through an electrochemical process, electropolishing removes a thin layer of material from stainless steel angles, resulting in a clean, smooth, and corrosion-resistant finish. This treatment enhances the steel's natural resistance to corrosion and eliminates surface imperfections. 4. Passivation: To eliminate iron contamination or embedded particles, passivation treats the surface of stainless steel angles with a chemical solution. This process restores the steel's corrosion resistance and forms a protective oxide layer, safeguarding it against further corrosion or oxidation. 5. Coating: Stainless steel angles can also be coated with various materials for added protection or altered appearance. Popular coating options include powder coating, which provides a durable and decorative finish, and PVD (Physical Vapor Deposition) coating, which creates a thin, hard, and decorative layer on the angle's surface. Choosing the right surface treatment for stainless steel angles depends on specific application requirements, such as aesthetics, corrosion resistance, and durability. It is crucial to consider the intended use and environment of the angles to select the most suitable surface treatment that meets desired performance and appearance goals.

- Q: What are the hygienic properties of stainless steel angle?

- Stainless steel angle has several hygienic properties that make it a popular choice for various applications. Firstly, stainless steel is non-porous, which means it does not absorb bacteria, dirt, or other contaminants. This makes it easy to clean and maintain a high level of hygiene. Additionally, stainless steel is resistant to corrosion, making it suitable for environments with moisture or chemicals that can degrade other materials. It also has a smooth surface, making it difficult for bacteria to adhere to and grow. Overall, stainless steel angle offers excellent hygienic properties, making it a preferred choice in industries such as food processing, healthcare, and pharmaceuticals.

- Q: Are stainless steel angles suitable for marine applications?

- Yes, stainless steel angles are highly suitable for marine applications. Stainless steel is known for its corrosion-resistant properties, making it ideal for use in marine environments where exposure to saltwater and high humidity can cause rapid deterioration of other materials. Stainless steel angles provide structural stability and durability while offering excellent resistance to corrosion, making them a reliable choice for various marine applications such as boat building, ship fittings, and offshore structures.

- Q: Can stainless steel angles be used in structural applications?

- Yes, stainless steel angles can be used in structural applications. Stainless steel is known for its high strength, durability, and corrosion resistance, making it suitable for various structural purposes. Stainless steel angles can provide structural support, reinforcement, and stability in buildings, bridges, machinery, and other structural projects. They can be used to frame structures, support beams and columns, create bracing and trusses, and provide overall stability and structural integrity. Additionally, stainless steel angles can withstand extreme weather conditions, high temperatures, and harsh environments, making them a reliable choice for structural applications.

- Q: How do stainless steel angles compare to other types of angles?

- Stainless steel angles are highly regarded for their superior strength, durability, and corrosion resistance, making them a preferred choice in various industries. When comparing stainless steel angles to other types of angles, such as aluminum or carbon steel angles, several key differences become apparent. One significant advantage of stainless steel angles is their exceptional resistance to corrosion. This property makes stainless steel angles ideal for applications that involve exposure to moisture, chemicals, or other corrosive elements. Unlike aluminum angles, which may corrode or develop oxidation over time, stainless steel angles maintain their integrity and appearance even in demanding environments. Furthermore, stainless steel angles exhibit remarkable strength and durability. Compared to aluminum angles, stainless steel angles have a higher tensile strength, allowing them to withstand heavier loads and more rigorous conditions. This strength also translates into excellent structural stability, making stainless steel angles a reliable choice for construction and engineering projects. In terms of aesthetics, stainless steel angles offer a sleek and modern appearance. They can be easily polished or brushed to achieve a desired finish, adding an attractive and professional touch to architectural designs or interior applications. Conversely, aluminum angles may have a less refined appearance and are often used in applications where weight reduction is a priority. Although stainless steel angles tend to be more expensive than aluminum angles, they provide a longer service life and reduced maintenance costs due to their corrosion-resistant properties. Additionally, stainless steel angles are recyclable, making them an environmentally friendly choice. In summary, stainless steel angles surpass other types of angles in terms of corrosion resistance, strength, durability, and aesthetic appeal. While aluminum angles may be lighter and more cost-effective, stainless steel angles offer unmatched performance and reliability, making them the preferred choice for a wide range of applications.

- Q: What is the composition of stainless steel angles?

- The primary components of stainless steel angles include iron, chromium, nickel, and other elements in varying amounts. The specific grade of stainless steel being used determines the exact composition. Chromium is added to the steel alloy to enhance its resistance to corrosion, while nickel improves its strength and durability. Additionally, smaller quantities of carbon, manganese, and molybdenum may be present to further enhance the strength and performance of stainless steel angles. The composition of stainless steel angles is carefully adjusted to provide a balanced combination of strength, corrosion resistance, and other desirable properties to suit different applications.

- Q: Can stainless steel angles be used in the production of equipment for the food industry?

- Stainless steel angles are indeed suitable for the manufacturing of food industry equipment. Their corrosion-resistant properties make stainless steel a favored choice in this sector, as it can withstand exposure to food and cleaning chemicals. Moreover, stainless steel angles offer structural support and stability when constructing conveyor systems, food processing machinery, and storage racks. Furthermore, stainless steel is effortless to clean and maintain, reducing the chances of contamination and upholding high hygiene standards in food production facilities. In conclusion, stainless steel angles are widely utilized and well-suited for the production of food industry equipment.

Send your message to us

GALVANIZED STEEL ENGLE BAR EQUAL STEEL BAR UNEQUAL STEEL BAR JIS GB

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords