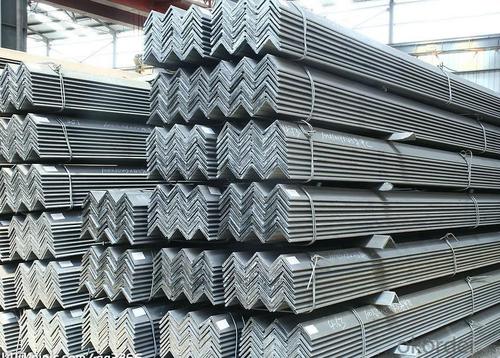

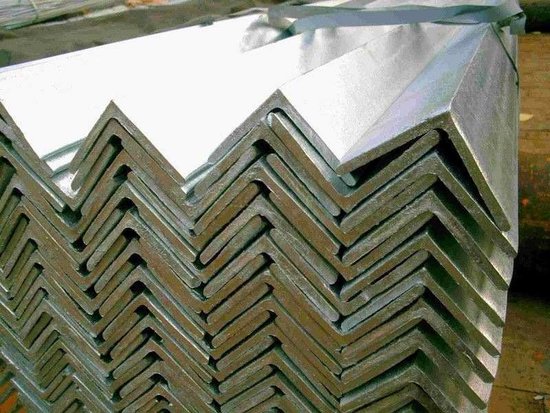

430 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Angles

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your

requirement

10. Application: Construction, Marine, Industry and so on

|

Name |

Stainless Steel Angles | ||||||

|

Standard |

ASTM A554, A312, A249, A269 and A270 | ||||||

|

Material Grade |

304,316,201,202, 316L,430 | ||||||

|

Length |

6m or as customers' request | ||||||

|

Tolerance |

a) thickness: +/-0. 15mm | ||||||

|

| |||||||

|

b) Length:+/-4. 5mm - 0mm | |||||||

|

Surface |

180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

|

Application |

Decoration construction, upholstery, industry instruments | ||||||

|

Test |

Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

|

Chemical Composition of Material |

Composition

Material |

201 |

202 |

304 |

316L |

430 | |

|

C |

≤0.15 |

≤0.15 |

≤0.08 |

≤0.08 |

≤0.12 | ||

|

Si |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 | ||

|

Mn |

5.5-7.5 |

7.5-10 |

≤2.00 |

≤2.00 |

≤1.00 | ||

|

P |

≤0.06 |

≤0.06 |

≤0.045 |

≤0.045 |

≤0.040 | ||

|

S |

≤0.03 |

≤0.03 |

≤0.030 |

≤0.030 |

≤0.030 | ||

|

Cr |

16-18 |

17-19 |

18-20 |

16-18 |

16-18 | ||

|

Ni |

3.5-5.5 |

4-6 |

8-10.5 |

10-14 |

| ||

|

Mo |

|

|

|

2.0-3.0 |

| ||

|

Mechanical Property |

Material Item |

201 |

202 |

304 |

316L | ||

|

Tensile Strength |

≥535 |

≥520 |

≥520 |

≥520 | |||

|

Yield Strength |

≥245 |

≥205 |

≥205 |

≥205 | |||

|

Extension |

≥30% |

≥30% |

≥35% |

≥35% | |||

|

Hardness (HV) |

<253 |

<253 |

<200 |

<200 | |||

- Q: What is the resistance to pitting of stainless steel angles?

- Stainless steel angles are typically highly resistant to pitting. Pitting is a localized form of corrosion that can occur in metals when exposed to chloride ions. It manifests as small pits or holes on the material's surface. Stainless steel angles are made from an alloy containing chromium, which creates a protective oxide layer on the steel's surface. This barrier prevents the penetration of corrosive substances and hinders pit formation. The higher the chromium content, the better the resistance to pitting corrosion. Additionally, the addition of other elements like molybdenum or nitrogen can further improve the resistance to pitting. These elements enhance the stainless steel's passivity and make it more resilient in aggressive environments with high chloride concentrations. It is important to consider that the resistance to pitting varies depending on the grade, composition, and specific usage environment of the stainless steel angle. To ensure maximum resistance to pitting, it is recommended to consult the manufacturer's specifications and guidelines when selecting the appropriate stainless steel grade for a particular application.

- Q: What is the difference between annealed and tempered stainless steel angles?

- Annealed stainless steel angles are softer and more malleable, making them easier to shape and manipulate. They are typically used in applications that require less strength and durability. On the other hand, tempered stainless steel angles are heat-treated to increase their strength and hardness. This makes them more resistant to wear, corrosion, and deformation, making them suitable for applications that require higher levels of strength and durability.

- Q: Are stainless steel angles suitable for toolboxes?

- Indeed, toolboxes can benefit from the use of stainless steel angles. Renowned for their durability, resistance to corrosion, and strength, stainless steel angles are an optimal selection for toolboxes. Enduring even the harshest conditions, such as moisture, chemicals, and extreme temperatures, stainless steel angles provide essential structural support and reinforcement, enabling toolboxes to withstand both the weight of their contents and external forces. Moreover, the inclusion of stainless steel angles adds an aesthetically pleasing touch to the overall appearance of the toolbox. All in all, stainless steel angles prove to be a dependable and enduring choice for toolboxes.

- Q: What are the different types of stainless steel angles available?

- There are several different types of stainless steel angles available, including equal angles, unequal angles, and L-shaped angles. Equal angles have equal sides and are commonly used for structural applications. Unequal angles have different side lengths and are often used in architectural and decorative projects. L-shaped angles, also known as corner brackets, are used to join two perpendicular pieces of stainless steel.

- Q: Are stainless steel angles available in custom sizes?

- Absolutely! You can find stainless steel angles in custom sizes. These angles are widely used in construction, engineering, and industrial sectors. They can be produced in specific dimensions to suit any project's distinct needs. To achieve custom sizes, individuals can collaborate with steel suppliers or manufacturers that offer fabrication services. These services involve cutting and shaping the stainless steel angles according to the desired specifications. By opting for this approach, one gains more flexibility while ensuring the angles perfectly fit the project's requirements.

- Q: How do you calculate the section modulus for a stainless steel angle?

- To calculate the section modulus for a stainless steel angle, you need to know the geometric properties of the angle. The section modulus (Z) is a measure of the stiffness of a cross-sectional shape and is used to determine the bending strength of a member. The formula to calculate the section modulus of an angle is Z = (b * h^2) / 6, where b is the width of the angle and h is the height of the angle. First, measure the width and height of the stainless steel angle. Make sure to use consistent units of measurement, such as inches or millimeters. Next, square the height measurement (h^2). Multiply this value by the width measurement (b), and then divide the result by 6. For example, let's say you have a stainless steel angle with a width of 2 inches and a height of 3 inches. First, calculate the square of the height: 3^2 = 9. Next, multiply the square of the height by the width: 9 * 2 = 18. Finally, divide the result by 6: 18 / 6 = 3. Therefore, the section modulus for this stainless steel angle is 3 square inches. Remember, the section modulus is a measure of the stiffness or resistance to bending, so a higher section modulus indicates a stronger and stiffer angle.

- Q: Can stainless steel angle be bent or formed?

- Indeed, stainless steel angle possesses the ability to undergo bending or forming processes. This is due to the fact that stainless steel is a pliable substance, allowing it to be molded or manipulated without suffering from fractures or breakages. Nevertheless, it is crucial to acknowledge that the extent to which bending or forming can be achieved is contingent upon the thickness and quality of the stainless steel angle. Thicker angles may demand greater force or specialized equipment in order to achieve the desired shape, while different grades of stainless steel may exhibit varying levels of pliability. To ensure the correct methods and safety precautions are observed, it is always advisable to seek guidance from a professional or adhere to the instructions provided by the manufacturer when endeavoring to bend or form stainless steel angle.

- Q: Can stainless steel angles be used for structural purposes?

- Yes, stainless steel angles can be used for structural purposes. Stainless steel is a strong and durable material that is well-suited for structural applications. Stainless steel angles are commonly used in construction, manufacturing, and engineering projects where strength and stability are crucial. They are often used to support heavy loads, provide structural stability, and create frameworks or supports. Stainless steel angles are resistant to corrosion, making them suitable for both indoor and outdoor applications. Additionally, stainless steel angles can be easily fabricated and welded, allowing for customization and versatility in structural designs. Overall, stainless steel angles are a reliable and popular choice for various structural purposes.

- Q: Can stainless steel angles be used in the aviation industry?

- Yes, stainless steel angles can be used in the aviation industry. Stainless steel is known for its high strength, corrosion resistance, and durability, making it an ideal material for various applications in the aviation industry. Stainless steel angles can be used in the construction of aircraft frames, wings, engine components, and other structural elements where strength and resistance to harsh environments are essential.

- Q: Can stainless steel angles be used for bike racks?

- Yes, stainless steel angles can be used for bike racks. Stainless steel is a durable and corrosion-resistant material, making it suitable for outdoor applications like bike racks. The angles can be used to provide structural support and stability for the racks.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

430 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords