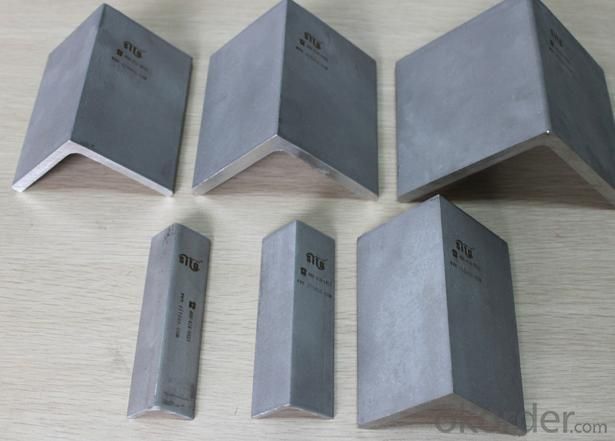

Unequal Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Angles

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your

requirement

10. Application: Construction, Marine, Industry and so on

|

Name |

Stainless Steel Angles | ||||||

|

Standard |

ASTM A554, A312, A249, A269 and A270 | ||||||

|

Material Grade |

304,316,201,202, 316L,430 | ||||||

|

Length |

6m or as customers' request | ||||||

|

Tolerance |

a) thickness: +/-0. 15mm | ||||||

|

| |||||||

|

b) Length:+/-4. 5mm - 0mm | |||||||

|

Surface |

180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

|

Application |

Decoration construction, upholstery, industry instruments | ||||||

|

Test |

Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

|

Chemical Composition of Material |

Composition

Material |

201 |

202 |

304 |

316L |

430 | |

|

C |

≤0.15 |

≤0.15 |

≤0.08 |

≤0.08 |

≤0.12 | ||

|

Si |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 | ||

|

Mn |

5.5-7.5 |

7.5-10 |

≤2.00 |

≤2.00 |

≤1.00 | ||

|

P |

≤0.06 |

≤0.06 |

≤0.045 |

≤0.045 |

≤0.040 | ||

|

S |

≤0.03 |

≤0.03 |

≤0.030 |

≤0.030 |

≤0.030 | ||

|

Cr |

16-18 |

17-19 |

18-20 |

16-18 |

16-18 | ||

|

Ni |

3.5-5.5 |

4-6 |

8-10.5 |

10-14 |

| ||

|

Mo |

|

|

|

2.0-3.0 |

| ||

|

Mechanical Property |

Material Item |

201 |

202 |

304 |

316L | ||

|

Tensile Strength |

≥535 |

≥520 |

≥520 |

≥520 | |||

|

Yield Strength |

≥245 |

≥205 |

≥205 |

≥205 | |||

|

Extension |

≥30% |

≥30% |

≥35% |

≥35% | |||

|

Hardness (HV) |

<253 |

<253 |

<200 |

<200 | |||

- Q: What are the strength properties of stainless steel angle?

- Stainless steel angle has excellent strength properties, including high yield and tensile strength. It is known for its durability, resistance to corrosion, and ability to withstand high temperatures. Additionally, stainless steel angle offers good structural stability and load-bearing capacity, making it suitable for various applications in construction, engineering, and industrial sectors.

- Q: Can stainless steel angles be used in the transportation industry?

- Indeed, the transportation industry can make use of stainless steel angles. Renowned for its durability, resistance to corrosion, and high strength-to-weight ratio, stainless steel proves to be an ideal material for various transportation applications. Vehicle frames, chassis, and structural components can be constructed with stainless steel angles, providing essential support and stability. Furthermore, trailers, railcars, and shipping containers often utilize stainless steel angles to endure harsh environmental conditions and heavy loads. Additionally, airports, bridges, and other transportation-related infrastructure projects incorporate stainless steel angles. The versatility and dependability of stainless steel render it a preferred option in the transportation industry.

- Q: What is the difference between 304L and 316L stainless steel angles?

- The composition and corrosion resistance properties are what differentiate 304L and 316L stainless steel angles. 304L stainless steel, a variation of the 304 grade with lower carbon content, is more resistant to sensitization. This makes it suitable for welding and reduces the risk of intergranular corrosion. It also offers good corrosion resistance in most atmospheric conditions and mild chemical environments. On the other hand, 316L stainless steel, a variation of the 316 grade known as marine-grade stainless steel, contains molybdenum which enhances its corrosion resistance, particularly against chlorides and aggressive environments. It is commonly used in marine applications, chemical processing plants, and medical equipment due to its superior resistance against pitting and crevice corrosion. Both 304L and 316L stainless steel angles possess excellent strength, toughness, and formability. However, 316L stainless steel is slightly stronger and more durable than 304L stainless steel. To choose between 304L and 316L stainless steel angles, one must consider the specific application and desired level of corrosion resistance. For marine or highly corrosive environments, 316L stainless steel angles are the better option. For general applications where corrosion resistance is not a primary concern, 304L stainless steel angles are a more cost-effective choice.

- Q: What are the standard finishes available for stainless steel angles?

- There are several standard finishes available for stainless steel angles. The most common ones include: 1. Mill finish: This is the standard finish for stainless steel angles straight from the mill. It has a dull, gray appearance and is not very aesthetically pleasing, but it is functional and provides good corrosion resistance. 2. Brushed finish: This finish is achieved by brushing the stainless steel surface with an abrasive material. It creates a uniform and shiny appearance with fine lines running in one direction. Brushed finishes are popular in architectural and decorative applications. 3. Polished finish: This finish involves polishing the stainless steel surface to a high shine. It removes scratches and imperfections, resulting in a mirror-like appearance. Polished finishes are often used in decorative and high-end applications. 4. Satin finish: This finish is similar to a brushed finish but has a smoother and less reflective appearance. It is achieved by using a fine abrasive material to create a soft and matte finish. Satin finishes are commonly used in architectural and industrial applications. 5. Bead blasted finish: In this finish, small glass beads are blasted onto the stainless steel surface under high pressure. It creates a uniform, matte appearance with a slightly rough texture. Bead blasted finishes are often used in applications where a low reflectivity and good grip are required. 6. PVD coating: PVD (Physical Vapor Deposition) is a process that involves depositing a thin layer of a colored material onto the stainless steel surface. This can create a wide range of colors and finishes, including gold, black, bronze, and more. PVD coatings are commonly used in decorative and architectural applications. These are just a few examples of the standard finishes available for stainless steel angles. The choice of finish depends on the desired appearance, functionality, and specific application requirements.

- Q: What is the difference between 304 and 316 stainless steel angle?

- The main difference between 304 and 316 stainless steel angle lies in their chemical composition and corrosion resistance. 304 stainless steel angle is made up of 18% chromium and 8% nickel, which gives it good corrosion resistance in general environments. It is commonly used for various applications such as architectural and structural components, trim, and kitchen equipment. However, it is not as resistant to corrosion in chloride environments, such as coastal areas or near saltwater. On the other hand, 316 stainless steel angle contains 16% chromium, 10% nickel, and 2% molybdenum. The addition of molybdenum enhances its corrosion resistance, making it suitable for use in more aggressive environments, including those with exposure to chlorides or acids. This makes 316 stainless steel angle ideal for marine applications, chemical processing, and areas with high levels of pollution. In summary, 304 stainless steel angle offers good corrosion resistance in general environments, while 316 stainless steel angle provides superior corrosion resistance, especially in chloride-rich or acidic environments. The choice between the two depends on the specific application and the level of corrosion resistance required.

- Q: What are the different thicknesses of stainless steel angles available?

- Various thicknesses of stainless steel angles are offered, typically measured in gauge numbers or millimeters. The common range for stainless steel angles is from 1/8-inch (3.18 mm) to 3/16-inch (4.76 mm), but they can also be found in thinner or thicker dimensions depending on specific needs. Thinner stainless steel angles, such as 1/16-inch (1.59 mm) or 1/32-inch (0.8 mm), may be suitable for lightweight applications, while thicker angles like 1/4-inch (6.35 mm) or 3/8-inch (9.52 mm) are often used for heavy-duty or structural purposes. It is worth noting that the availability of different thicknesses may vary among suppliers or manufacturers.

- Q: What are the different shapes available in stainless steel angles?

- Stainless steel angles are available in various shapes including equal angles, unequal angles, L-shaped angles, and rounded angles.

- Q: What are the different types of stainless steel angles profiles used in industrial applications?

- In industrial applications, stainless steel angle profiles are widely used for their strength, stability, and corrosion resistance. There are several types of these profiles commonly utilized: 1. Equal Leg Angle: This stainless steel angle has legs of equal length, forming a 90-degree angle. It is commonly employed in structural applications such as constructing frames, supports, and bracing. 2. Unequal Leg Angle: Also referred to as L-shaped angles, these stainless steel angles have legs of varying lengths. They find use in applications where one leg needs to be longer or shorter than the other, such as in machinery supports or frames. 3. Stainless Steel C Channel: C channel angles resemble the letter "C," with one long horizontal leg and two short vertical legs. They are frequently employed in the construction and manufacturing industries for support beams, architectural framing, and equipment racks. 4. Stainless Steel T Channel: T channel angles resemble the letter "T," featuring one long vertical leg and a shorter horizontal leg. They are commonly found in industrial applications requiring support, such as conveyor systems, structural framing, and machinery assembly. 5. Stainless Steel U Channel: U channel angles have a shape resembling the letter "U," with two parallel legs and a connecting base. They are commonly used in industrial applications where stability and support are crucial, such as building frames, truck bed rails, and equipment enclosures. 6. Stainless Steel Z Angle: Z angles have a shape similar to the letter "Z," with two legs forming a 90-degree angle and a connecting base. They are frequently utilized in industrial applications that necessitate increased strength and stability, such as shelving units, storage racks, and architectural trims. These stainless steel angle profiles come in different grades, such as 304 and 316, which offer varying levels of corrosion resistance and durability. The selection of profile type and grade depends on the specific requirements of the industrial application, such as load-bearing capacity, exposure to harsh environments, and aesthetic considerations.

- Q: Can stainless steel angles be used in bridge construction?

- Yes, stainless steel angles can be used in bridge construction. Stainless steel is a versatile and durable material that offers excellent corrosion resistance, high strength, and low maintenance requirements. These qualities make stainless steel angles suitable for a wide range of applications, including bridges. Stainless steel angles are often used in bridge construction for various purposes. They can be used as reinforcement in concrete bridges, providing additional strength and stability. Stainless steel angles can also be used for structural purposes, such as supporting beams and columns. Additionally, they can be used for aesthetic purposes, as stainless steel angles can add a modern and sleek appearance to bridge designs. One of the key advantages of using stainless steel angles in bridge construction is their resistance to corrosion. Bridges are exposed to various environmental conditions, including moisture, humidity, and chemicals, which can cause corrosion in traditional construction materials. However, stainless steel angles are highly resistant to corrosion, ensuring the long-term structural integrity of the bridge. Furthermore, stainless steel angles offer high strength-to-weight ratio, which is beneficial for bridge construction. This means that stainless steel angles can provide the required strength while minimizing the weight of the bridge structure. This advantage is particularly important for large-scale bridges, where reducing the weight can result in cost savings and improved performance. In summary, stainless steel angles can be effectively used in bridge construction due to their corrosion resistance, high strength, and aesthetic appeal. Their versatility and durability make them a suitable choice for various structural and reinforcement applications in bridges.

- Q: How do stainless steel angles contribute to architectural durability?

- Stainless steel angles contribute to architectural durability by providing structural support and resistance to corrosion, which ensures the longevity and stability of buildings. The high strength and corrosion-resistant properties of stainless steel angles make them ideal for withstanding harsh environmental conditions, such as exposure to moisture, UV rays, and extreme temperatures. Moreover, their versatility allows for various architectural designs and applications, enhancing both the structural integrity and aesthetic appeal of buildings.

1. Manufacturer Overview

| Location | Wuxi,China |

| Year Established | 2003 |

| Annual Output Value | Above US$8.3 Million |

| Main Markets | SouthEast Asia |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above21,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Unequal Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords