Q345 U shaped Channel Steel Hot Rolled Channel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Q345 U shaped Channel Steel Hot Rolled Channel

Main Structure of Hot Rolled Channel

| 1.Product size | Size : 5#--40# | ||||

| 2.Product length | Lengths : 6m--12m | ||||

| 3.product standard | Standard : GB, ASTM, JIS, DIN | ||||

| 4.product Grade | Grades : Q235B, Q345B, SS400 | ||||

| 5.Application | Used or building structures, vehicle | ||||

| manufacturing and other industrial structures | |||||

| 6.Customized requirement | Can produce special specification products | ||||

| as per our customers' requirement | |||||

| 7.Delivery time | 15-30 days after recieve the LC or pre-paid | ||||

| 8.Detail Package | Bundles, seaworthy wooden cases with or without | ||||

| edge protector, steel hoop and seals, or as per | |||||

| customers' requirements | |||||

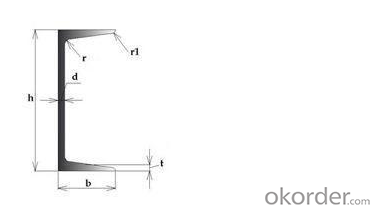

Drawings And Detail Datas (help to know more detail information)

Specification:

Specification | h | b | d | t | Cm2 | (kg/m) |

5 | 50 | 37 | 4.5 | 7 | 6.93 | 5.44 |

6.3 | 63 | 40 | 4.8 | 7.5 | 8.45 | 6.63 |

8 | 80 | 43 | 5 | 8 | 10.24 | 8.04 |

10 | 100 | 48 | 5.3 | 8.5 | 12.74 | 10 |

12.6 | 126 | 53 | 5.5 | 9 | 15.69 | 12.37 |

14a | 140 | 58 | 6 | 9.5 | 18.51 | 14.53 |

14b | 140 | 60 | 8 | 9.5 | 21.31 | 16.73 |

16a | 160 | 63 | 6.5 | 10 | 21.95 | 17.23 |

16 | 160 | 65 | 8.5 | 10 | 25.15 | 19.74 |

18a | 180 | 68 | 7 | 10.5 | 25.69 | 20.17 |

18 | 180 | 70 | 9 | 10.5 | 29.29 | 22.99 |

FAQ:

How's your service?

A:1. Offer customers 24/7 service, whenever you need us, we are always here for you.

2. Immediate response. Your any inquiry will be replied within 24 hours.

3. Support small order quantity, for the first time cooperation customers, we can send you less quantity for trial order.

4. Support third party inspection company to inspect and check the quality and quantity before delivery.

Picture:

- Q: Can stainless steel angles be galvanized?

- No, stainless steel angles cannot be galvanized as they are already corrosion-resistant and do not require additional coating for protection.

- Q: How do you store stainless steel angles?

- Stainless steel angles can be stored in a dry and well-ventilated area to prevent moisture and humidity from causing corrosion. It is advisable to keep them in an upright position, preferably on a pallet or rack, to avoid any distortion or damage. Additionally, using protective covers or wrapping them in a suitable material can provide an extra layer of safeguard against scratches or dents.

- Q: How does stainless steel angle perform in acidic environments?

- Stainless steel angle performs exceptionally well in acidic environments due to its high resistance to corrosion. The main component of stainless steel is chromium, which forms a protective passive layer on the surface when exposed to oxygen. This layer acts as a barrier, preventing the acid from reaching the underlying metal and causing corrosion. The chromium content in stainless steel angle is typically above 10.5%, which enables it to resist various corrosive agents, including acids. The passive layer formed on the stainless steel surface is stable and self-healing, meaning that even if it is damaged or scratched, it can quickly reform and continue protecting the metal against acid attack. Different grades of stainless steel may exhibit varying levels of acid resistance. For instance, austenitic stainless steel grades containing higher amounts of nickel and molybdenum, such as 316 and 317, have enhanced resistance to corrosive acids like sulfuric acid and hydrochloric acid. In acidic environments, stainless steel angle maintains its structural integrity and retains its strength and durability. It does not undergo significant corrosion, pitting, or cracking, making it an excellent choice for applications where exposure to acids is expected. However, it is important to note that prolonged exposure to highly concentrated acids or extremely low pH levels can still cause some corrosion or damage to stainless steel. Therefore, it is crucial to select the appropriate grade of stainless steel angle based on the specific acidic environment and concentration levels to ensure optimal performance and longevity.

- Q: Can stainless steel angles be used in the automotive industry?

- Yes, stainless steel angles can be used in the automotive industry. Stainless steel has excellent corrosion resistance, which is important in a high-moisture and salt-rich environment like the automotive industry. Stainless steel angles can be used in various applications such as structural components, brackets, supports, and frames. They offer strength and durability, making them suitable for withstanding the rigors of daily use and harsh conditions on the road. Additionally, stainless steel angles can be easily welded, allowing for customization and ease of assembly in automotive manufacturing processes. Overall, stainless steel angles are a reliable and versatile material choice for the automotive industry.

- Q: What are the different surface coatings available for stainless steel angles?

- There are several different surface coatings available for stainless steel angles, each offering unique benefits and characteristics. One common surface coating option is a brushed finish, which creates a textured look by brushing the surface of the stainless steel with a fine abrasive material. This finish helps to hide any scratches or imperfections on the surface, making it ideal for applications where aesthetics are important, such as architectural or decorative purposes. Another popular option is a polished finish, which involves buffing the stainless steel surface to a high shine. This coating not only enhances the appearance of the angles, but also improves their corrosion resistance and makes them easier to clean. Polished stainless steel angles are commonly used in food processing, pharmaceutical, and medical applications, where hygiene and cleanliness are crucial. For outdoor or harsh environments, a powder-coated finish is often recommended. This coating involves applying a dry powder to the stainless steel angles and then baking it in an oven to create a durable and protective layer. Powder coating provides excellent resistance to corrosion, UV rays, and chemicals, making it suitable for outdoor structures, marine applications, and industrial equipment. In some cases, stainless steel angles may also be coated with a layer of paint or an organic coating, providing additional protection against corrosion and other environmental factors. These coatings can be customized to match specific color requirements or to provide specific functionalities such as heat resistance or anti-graffiti properties. Ultimately, the choice of surface coating for stainless steel angles depends on the intended application, aesthetics, and the level of protection required. It is always important to consult with a professional or supplier to determine the most suitable coating option for a specific project.

- Q: What are the different types of stainless steel angles profiles?

- There are several different types of stainless steel angle profiles available, each with their own unique characteristics and applications. Some of the most common types include: 1. Equal Leg Angle: This type of stainless steel angle has equal dimensions on both legs, making it ideal for applications where symmetry is important. It is commonly used in structural applications, such as construction and fabrication projects. 2. Unequal Leg Angle: As the name suggests, this type of stainless steel angle has unequal dimensions on its legs. It is often used in applications where one leg needs to be longer or shorter than the other, such as framing or bracing. 3. L-Shaped Angle: This profile features a 90-degree angle, forming an L-shape. It is commonly used in corners or as a support for shelves, cabinets, or countertops. 4. Rounded Edge Angle: This type of stainless steel angle has rounded edges instead of sharp corners. It is often used in applications where safety is a concern, such as playground equipment or handrails. 5. Slotted Angle: Slotted stainless steel angles have holes or slots along their length, allowing for easy attachment and adjustment. They are frequently used in shelving systems, racks, or framework where flexibility and adjustability are crucial. 6. Decorative Angle: These angles are designed to enhance the aesthetic appeal of a space. They come in various patterns and finishes, making them suitable for architectural or interior design purposes. It's worth noting that these are just a few examples of the many stainless steel angle profiles available. The specific type of angle profile chosen depends on the intended use, load-bearing requirements, and aesthetic preferences of the project.

- Q: What is the maximum length tolerance for stainless steel angles?

- The maximum length tolerance for stainless steel angles can vary depending on the specific grade and manufacturing standards. However, in general, the maximum length tolerance for stainless steel angles is typically within a range of +/- 1/8 inch or +/- 3mm.

- Q: What surface finishes are available for stainless steel angles?

- There are several surface finishes available for stainless steel angles, including brushed, polished, mirror, and mill finishes.

- Q: How does stainless steel angle perform in radiation environments?

- Stainless steel angle is known for its excellent corrosion resistance, strength, and durability, making it a popular choice for various applications. In radiation environments, stainless steel angle performs exceptionally well due to its unique properties. Firstly, stainless steel contains a high percentage of chromium, which forms a protective oxide layer on the surface of the metal. This oxide layer acts as a barrier, preventing the penetration of moisture, chemicals, and other corrosive agents. As a result, stainless steel angle exhibits superior resistance to corrosion, even in radiation environments where moisture and chemicals might be present. Additionally, stainless steel angle can withstand high temperatures without losing its strength and structural integrity. This is especially crucial in radiation environments where heat and thermal fluctuations are common. The ability of stainless steel to maintain its mechanical properties at elevated temperatures ensures its performance remains unaffected by radiation-induced heat. Moreover, stainless steel angle is known for its excellent mechanical properties, including high tensile and yield strength. This strength allows it to withstand the rigors of radiation environments, such as vibrations and structural stresses, without experiencing deformation or failure. This ensures the longevity and reliability of stainless steel angle in these challenging conditions. Furthermore, stainless steel angle exhibits good resistance to radiation-induced embrittlement. Radiation exposure can cause metal alloys to become brittle and prone to cracking. However, stainless steel's composition, including elements like nickel and molybdenum, helps mitigate the effects of radiation-induced embrittlement, ensuring its structural integrity remains intact. Lastly, stainless steel angle is easy to clean and maintain, which is crucial in radiation environments where contamination control is vital. Its smooth surface and corrosion resistance allow for thorough cleaning and sterilization, preventing the buildup of radioactive particles or other contaminants. In conclusion, stainless steel angle performs exceptionally well in radiation environments due to its corrosion resistance, high temperature resistance, mechanical strength, resistance to embrittlement, and ease of maintenance. Its unique properties make it a reliable and durable choice for applications where radiation exposure is a concern.

- Q: What is the electrical conductivity of stainless steel angles?

- The electrical conductivity of stainless steel angles is relatively low compared to other metals due to its high resistance to electrical flow.

Send your message to us

Q345 U shaped Channel Steel Hot Rolled Channel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords