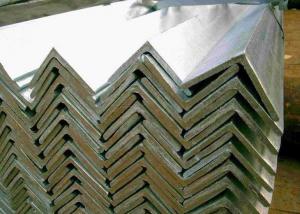

Best Quality for 201 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Angles

General Information of Stainless Steel Angles

1. Grade: SS200, 300,400 series

2. Size: 25×25×3 mm-100×100×10mm

3. Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package: Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry and so on.

Specification of Stainless Steel Angles

Name | Stainless Steel Angles | |||||

Standard | ASTM A554, A312, A249, A269 and A270 | |||||

Material Grade | 304,316,201,202, 316L,430 | |||||

Length | 6m or as customers' request | |||||

Tolerance | a) Thickness: +/-0. 15mm | |||||

b) Length: +/-4. 5mm - 0mm | ||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | |||||

Application | Decoration construction, upholstery, industry instruments | |||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | |||||

Chemical Composition of Material | Composition Material | 201 | 202 | 304 | 316 | 430 |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | |

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | |

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | ||

Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

Hardness (HV) | <253 | <253 | <200 | <200 | ||

- Q: How do you calculate the plastic section modulus of a stainless steel angle?

- The plastic section modulus of a stainless steel angle can be calculated by determining the moment of inertia of the angle cross-section and dividing it by the distance from the centroid of the section to the furthest point on the section.

- Q: What are the different grades of stainless steel used for angles?

- There are several different grades of stainless steel that are commonly used for angles, each with its own unique properties and characteristics. The grades of stainless steel used for angles vary depending on the specific application and the desired level of corrosion resistance, strength, and aesthetic appeal. One of the most commonly used grades of stainless steel for angles is 304 stainless steel. This grade is known for its excellent corrosion resistance, making it suitable for applications in harsh environments or where contact with moisture is expected. It also offers good strength and formability, making it versatile for various structural and decorative purposes. Another popular grade is 316 stainless steel, which is highly corrosion resistant and often used in marine environments or in applications exposed to chlorides or other corrosive substances. It provides superior resistance to pitting, crevice corrosion, and stress corrosion cracking, making it ideal for angles used in coastal areas or in chemical processing plants. In addition to 304 and 316 stainless steel, there are other grades used for angles, such as 430 stainless steel, which offers good corrosion resistance but is less resistant to extreme temperatures and not as strong as the aforementioned grades. Duplex stainless steels, such as 2205, are also used for angles, as they provide a combination of high strength and excellent corrosion resistance. Ultimately, the choice of grade depends on the specific requirements of the application. Factors such as the environment, intended use, and budget will play a role in determining the most suitable grade of stainless steel for angles. Consulting with a knowledgeable professional or engineer can help in selecting the appropriate grade for a particular project.

- Q: What are the different manufacturing standards for stainless steel angles?

- Stainless steel angles adhere to various manufacturing standards in order to meet specific requirements and quality standards. Some commonly utilized manufacturing standards for stainless steel angles include: 1. ASTM A276: This standard outlines the specifications for stainless steel angles in both hot-rolled and cold-finished conditions. It encompasses multiple grades of stainless steel and provides guidelines for chemical composition, mechanical properties, heat treatment, and tolerances. 2. EN 10056: As a European standard, this mandates the tolerances, dimensions, and sectional properties of stainless steel angles. It encompasses a wide range of dimensions and offers guidance for the production process, including rolling and heat treatment. 3. DIN 1028: This German standard specifies the dimensions, tolerances, and static values for hot-rolled stainless steel angles. It offers guidelines for the production process, including rolling and heat treatment, while ensuring the product adheres to specific quality requirements. 4. JIS G 4317: As a Japanese standard, this provides specifications for hot-formed stainless steel sections, including angles. It offers guidelines for the chemical composition, mechanical properties, and heat treatment of stainless steel angles. 5. GB/T 706-2008: This Chinese standard details the dimensions, shape, weight, and tolerances of hot-rolled stainless steel angles. It covers multiple grades of stainless steel and provides guidelines for the production process, including rolling and heat treatment. These manufacturing standards guarantee consistent production and ensure stainless steel angles meet the necessary specifications for diverse applications. Manufacturers, suppliers, and customers rely on these standards to ensure the quality and dependability of stainless steel angles in construction, architectural, and industrial settings.

- Q: Can stainless steel angles be used in architectural designs?

- Architectural designs can definitely benefit from the use of stainless steel angles. With their combination of strength, durability, and aesthetic appeal, stainless steel proves to be a highly versatile material. In architectural applications, stainless steel angles are frequently utilized not only for structural support but also to enhance the overall visual appeal of the design. They can be employed to achieve sleek and contemporary lines or to incorporate decorative accents into buildings and structures. Additionally, stainless steel angles boast exceptional resistance to corrosion, making them suitable for both indoor and outdoor use. Architects and designers choose stainless steel angles for various architectural elements such as staircases, handrails, façades, and more due to their adaptability and long-lasting performance.

- Q: What are the standard lengths for stainless steel angles?

- The standard lengths for stainless steel angles can vary depending on the manufacturer and specific requirements. However, common standard lengths for stainless steel angles typically range from 10 feet to 20 feet.

- Q: How do stainless steel angles contribute to energy efficiency?

- Stainless steel angles contribute to energy efficiency by providing structural support and enhancing the insulation of buildings. These angles are commonly used in construction to reinforce walls and roofs, reducing the need for additional energy-consuming materials. Additionally, stainless steel's high thermal conductivity helps in maintaining consistent indoor temperatures, minimizing the need for excessive heating or cooling. Overall, stainless steel angles play a crucial role in improving energy efficiency by promoting sustainable construction practices and reducing energy consumption in buildings.

- Q: Can stainless steel angle be used in power generation facilities?

- Yes, stainless steel angle can be used in power generation facilities. Stainless steel is known for its high strength, durability, corrosion resistance, and heat resistance properties, which make it suitable for various applications in power generation plants. It can be used for structural support, equipment mounting, and various other purposes in power generation facilities.

- Q: How do you measure the length of a stainless steel angle?

- To measure the length of a stainless steel angle, you would typically use a measuring tape or a ruler. Place one end of the measuring tool at one corner of the angle and extend it to the opposite corner, ensuring that you measure along the longest side of the angle. Take note of the measurement displayed on the tape or ruler, which will give you the length of the stainless steel angle.

- Q: Can stainless steel angles be used in high-pressure applications?

- Yes, stainless steel angles can be used in high-pressure applications. Stainless steel is known for its excellent corrosion resistance, durability, and strength, making it suitable for various industrial and structural applications. Stainless steel angles are commonly used in high-pressure environments such as piping systems, hydraulic systems, and pressure vessels. The high strength and corrosion resistance of stainless steel ensure that it can withstand the pressure and prevent any leaks or failures. Additionally, stainless steel angles can be fabricated and welded to meet specific requirements, making them versatile for different high-pressure applications.

- Q: Can stainless steel angles be cut to a specific length?

- Yes, stainless steel angles can be cut to a specific length. Stainless steel angles are versatile and can be cut to any desired length using various cutting tools such as band saws, circular saws, or plasma cutters. The specific length can be achieved by measuring the angle accurately and then using the appropriate cutting tool to trim it to the desired size. It is important to use the correct cutting technique and tools to ensure a clean and precise cut in order to maintain the structural integrity and aesthetics of the stainless steel angle.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | China, East Asia, |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for 201 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords