Galvanized U Shaped Channel Steel Beam for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized U Shaped Channel Steel Beam for Construction

Products Information

1.Size | Size : 5#--40# | ||||

2.Length | Lengths : 6m--12m | ||||

3.Standard | Standard : GB, ASTM, JIS, DIN | ||||

4.Grade | Grades : Q235B, Q345B, SS400 | ||||

5.Application | Used or building structures, vehicle | ||||

manufacturing and other industrial structures or construction | |||||

6.Customized Requirement | Can produce special specification products | ||||

as per our customers' requirement | |||||

7.Lead time | 15-30 days after recieving the L/C or pre-paid | ||||

8.Package | Bundles, seaworthy wooden cases with or without | ||||

edge protector, steel hoop and seals, or as per | |||||

customers' requirements | |||||

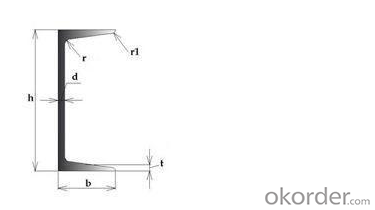

9.Remark | For detail structure you may check the below drawings and data for know more | ||||

Drawings & Detail Datas

Specification

Specification | h | b | d | t | Cm2 | (kg/m) |

5 | 50 | 37 | 4.5 | 7 | 6.93 | 5.44 |

6.3 | 63 | 40 | 4.8 | 7.5 | 8.45 | 6.63 |

8 | 80 | 43 | 5 | 8 | 10.24 | 8.04 |

10 | 100 | 48 | 5.3 | 8.5 | 12.74 | 10 |

12.6 | 126 | 53 | 5.5 | 9 | 15.69 | 12.37 |

14a | 140 | 58 | 6 | 9.5 | 18.51 | 14.53 |

14b | 140 | 60 | 8 | 9.5 | 21.31 | 16.73 |

16a | 160 | 63 | 6.5 | 10 | 21.95 | 17.23 |

16 | 160 | 65 | 8.5 | 10 | 25.15 | 19.74 |

18a | 180 | 68 | 7 | 10.5 | 25.69 | 20.17 |

18 | 180 | 70 | 9 | 10.5 | 29.29 | 22.99 |

Picture

- Q: What are the different types of edge finishes for slotted stainless steel angles?

- There are several types of edge finishes for slotted stainless steel angles, including straight cut, rounded, chamfered, and beveled edges.

- Q: What is the difference between 321 and 316 stainless steel angles?

- The main difference between 321 and 316 stainless steel angles lies in their chemical composition and mechanical properties. 321 stainless steel is a stabilized version of 304 stainless steel, containing titanium as a stabilizing element. This addition helps to prevent the material from sensitization, which is a process that occurs when stainless steel is exposed to high temperatures for extended periods of time, causing it to become susceptible to corrosion. As a result, 321 stainless steel angles are often used in high-temperature applications, such as in exhaust systems or furnace parts. On the other hand, 316 stainless steel angles are part of the austenitic family of stainless steels and are known for their excellent corrosion resistance properties. They contain higher amounts of molybdenum than 321 stainless steel, which enhances their resistance to pitting and crevice corrosion in chloride environments. Due to this superior corrosion resistance, 316 stainless steel angles are commonly used in marine and coastal applications where exposure to saltwater is a concern. In terms of mechanical properties, 321 stainless steel angles exhibit good formability and weldability, similar to 304 stainless steel. They have a higher strength and hardness compared to 316 stainless steel angles, making them suitable for structural applications that require increased durability. In summary, while both 321 and 316 stainless steel angles are corrosion-resistant alloys, 321 stainless steel is specifically designed for high-temperature environments and is more resistant to sensitization, while 316 stainless steel offers superior corrosion resistance in chloride environments. The choice between the two will depend on the specific application requirements and the level of corrosion resistance needed.

- Q: Can stainless steel angles be used in machinery frames?

- Indeed, machinery frames can utilize stainless steel angles. Renowned for their exceptional strength, durability, and resistance to corrosion, stainless steel angles prove fitting for diverse applications, including machinery frames. They effectively furnish structural reinforcement, stability, and firmness to the machinery frame, guaranteeing its endurance and efficacy. Moreover, stainless steel angles readily endure challenging environments, excessive vibrations, and substantial loads, rendering them an optimal selection for machinery frames.

- Q: What are the chemical resistance properties of stainless steel angle?

- Stainless steel angle has excellent chemical resistance properties due to its high chromium content, which forms a protective oxide layer on the surface. This oxide layer prevents corrosion and makes stainless steel angle resistant to various chemicals, including acids, bases, and many organic compounds.

- Q: What is the weight capacity of stainless steel angles?

- The weight capacity of stainless steel angles can vary depending on the specific dimensions and thickness of the angle. It is important to refer to the manufacturer's specifications or consult an engineer to determine the weight capacity of a particular stainless steel angle.

- Q: Can stainless steel angles be used in wastewater treatment facilities?

- Yes, stainless steel angles can be used in wastewater treatment facilities. Stainless steel is highly resistant to corrosion and can withstand the harsh chemical environment found in wastewater treatment facilities. It is also easy to clean and maintain, making it a suitable choice for various applications such as structural support, piping, and equipment in these facilities.

- Q: Can stainless steel angle be used in power generation facilities?

- Stainless steel angle is indeed applicable for power generation facilities. Its remarkable corrosion resistance and robustness make it appropriate for the demanding conditions typically present in such environments. It is frequently employed for different purposes, including supporting structures, brackets, and frames for machinery and equipment. By offering strength and stability, stainless steel angle guarantees the endurance and durability of the structures within power generation facilities. Moreover, stainless steel possesses high temperature resistance and can endure the thermal pressures commonly encountered during power generation procedures. Its ability to resist oxidation and erosion renders it an ideal material for implementation in power plants, encompassing nuclear, thermal, and renewable energy facilities.

- Q: Can stainless steel angles be used in wastewater treatment applications?

- Stainless steel angles are capable of being utilized in wastewater treatment applications. In the wastewater treatment sector, stainless steel is extensively employed owing to its exceptional corrosion resistance properties, which play a vital role in managing aggressive and corrosive wastewater. Structural support is provided by stainless steel angles and they can be employed in a range of components including tanks, pipes, and pumps. These angles are impervious to rust, staining, and degradation, ensuring their longevity and durability even in harsh surroundings. Moreover, stainless steel possesses hygienic qualities, is easy to clean, and can withstand high temperatures and pressures. These attributes make stainless steel angles an optimal selection for wastewater treatment applications where durability, corrosion resistance, and hygiene are of utmost importance.

- Q: Can stainless steel angles be recycled?

- Yes, stainless steel angles can be recycled. Stainless steel is a highly recyclable material, and it retains its properties even after multiple recycling processes. Recycling stainless steel angles not only reduces the demand for new raw materials but also helps conserve energy and reduce greenhouse gas emissions associated with the production of new stainless steel. Stainless steel is a valuable material in the recycling industry as it can be melted down and reused to produce new stainless steel products without losing its strength and durability.

- Q: How do stainless steel angles compare to aluminum angles?

- Stainless steel angles are generally stronger and more durable than aluminum angles. They have higher corrosion resistance and can withstand harsh environmental conditions. However, aluminum angles are lighter in weight and more cost-effective. The choice between stainless steel and aluminum angles depends on the specific application requirements and budget constraints.

Send your message to us

Galvanized U Shaped Channel Steel Beam for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords