Galvanized Steel Products of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

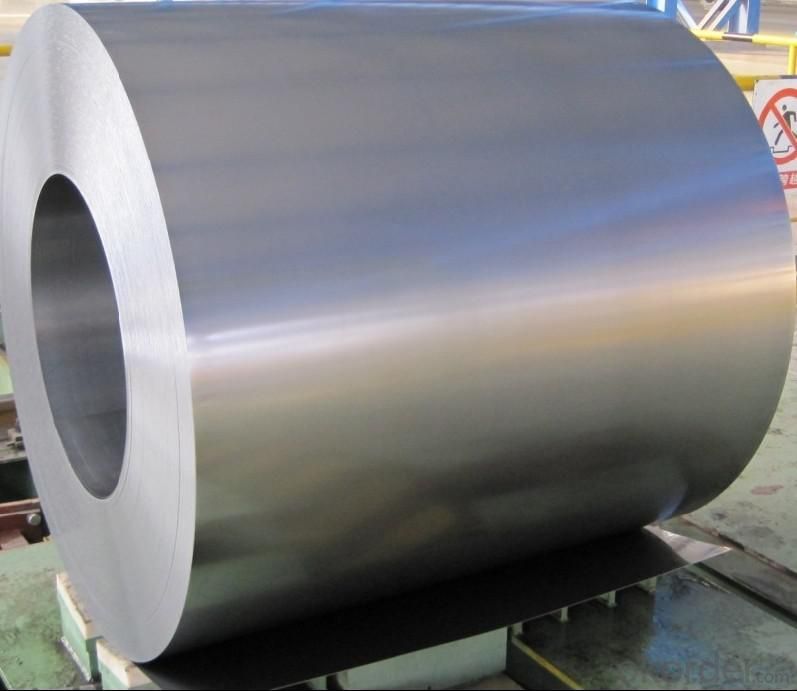

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

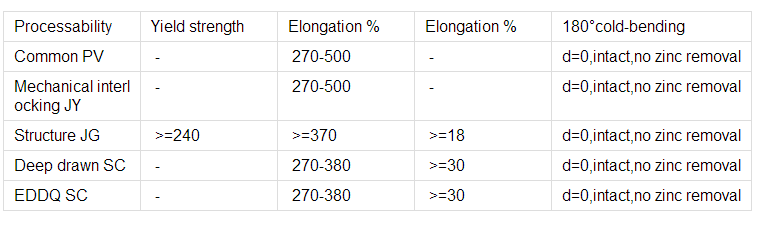

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of shipping containers?

- Steel coils are used in the manufacturing of shipping containers as they are rolled into sheets, which are then cut and welded to create the walls, roof, and floor of the container. The high strength and durability of steel coils ensure that the shipping containers can withstand the rigors of transportation, protecting the goods inside.

- Q: I'm a hiker and cook on a camp fire with a canteen cup. So which would be a better material for cooking on a campfire with, aluminum or stainless steel?

- Direct fire will kind of ruin stainless steel. I've screwed up several stainless steel pans cooking directly on a campfire. I have to agree with wildflower the best route by far in a small cast iron pan. They are pretty heavy though.

- Q: What are the common methods of forming steel coils?

- The common methods of forming steel coils include hot rolling, cold rolling, and strip casting.

- Q: What is the difference between steel coils and steel sheets?

- Steel coils and steel sheets differ primarily in their form and dimensions. Steel coils are long, continuous rolls of steel that have been wound up after being processed. They are typically produced in large quantities and are used in various industries, such as automotive and construction. Steel sheets, on the other hand, are flat pieces of steel that have been cut from coils or directly produced in a flat form. They come in different sizes and thicknesses, making them more suitable for specific applications such as roofing, cladding, or fabrication. In summary, while steel coils are the raw material for steel sheets, the main distinction is that coils are long rolls, while sheets are flat pieces of steel.

- Q: What are the common coil thicknesses available for steel coils?

- The common coil thicknesses available for steel coils can vary depending on the specific application and industry requirements. However, some of the most common coil thicknesses for steel coils range from 0.5mm to 3mm. These thicknesses are commonly used in various manufacturing processes, including automotive, construction, and appliance industries. For lightweight applications or where flexibility is required, thinner steel coils with thicknesses ranging from 0.5mm to 1.5mm are often used. These thinner coils are suitable for applications such as automotive body panels, roofing, and general sheet metal fabrication. On the other hand, for applications that require higher strength and durability, thicker steel coils with thicknesses ranging from 1.5mm to 3mm are commonly used. These thicker coils are often utilized in heavy-duty construction, structural components, and industrial equipment manufacturing. It is important to note that these are just general ranges, and specific coil thicknesses can vary depending on the specific requirements of a particular project or customer preference. Steel coil thicknesses can be customized to meet specific needs, allowing for greater flexibility in various industries.

- Q: What are the common applications of coated steel coils?

- Some common applications of coated steel coils include manufacturing of automotive parts, construction materials such as roofing and siding, appliances, and electrical equipment. They are also used in the production of household goods such as furniture, shelving, and storage racks. Additionally, coated steel coils find applications in the transportation industry for manufacturing trailers, shipping containers, and railway cars due to their durability and corrosion resistance.

- Q: Can steel coils be returned if they are damaged?

- Yes, steel coils can typically be returned if they are damaged. However, the return policy may vary depending on the supplier or manufacturer. It is advisable to contact the seller or review the terms and conditions of the purchase to determine the specific return policy for damaged steel coils.

- Q: How are steel coils used in the production of electrical equipment?

- Steel coils are used in the production of electrical equipment as they serve as the core component for transformers. The coils are made from high-quality steel to ensure efficient electrical conductivity and magnetic properties. They are wound around a core to create an electromagnetic field that helps in the transformation of voltage levels, enabling the smooth transmission and distribution of electricity.

- Q: How are steel coils used in the production of agricultural machinery parts?

- Steel coils are commonly used in the production of agricultural machinery parts due to their strength and versatility. Agricultural machinery parts such as blades, plowshares, and cultivator tines require materials that are durable and able to withstand harsh conditions. Steel coils provide the necessary strength and durability to these parts. The process starts with the steel coils being unwound and cut into the desired lengths. These lengths are then fed into a machine where they undergo various shaping processes such as bending, cutting, and stamping. This allows the steel to be formed into the specific shapes required for agricultural machinery parts. Once the desired shape is achieved, the steel parts are often heat-treated to enhance their strength and durability. This process involves heating the parts to high temperatures and then rapidly cooling them. Heat treatment increases the hardness and toughness of the steel, making it more resistant to wear and tear in the agricultural field. After heat treatment, the steel parts may undergo additional processes such as welding, surface coating, or painting, depending on the specific requirements of the machinery. These processes further enhance the durability and longevity of the parts. Overall, steel coils play a crucial role in the production of agricultural machinery parts by providing the necessary strength, durability, and versatility. The use of steel coils ensures that these parts can withstand the demanding conditions of agricultural operations, ultimately contributing to the efficiency and productivity of the farming industry.

- Q: I need to know what steel's weakness is.

- Steel has three weaknesses. They are Fire, Fighting, and Ground. Ice, Flying, Psychic, Bug, Rock, Ghost, Dragon, Steel and Normal aren't effect on Steel pokemon, so I would advise not to use those types. And Poison causes NO damage whatsoever on Steel pokemon. Water and Electric type moves cause normal damage. Happy Pokemoning! :)

Send your message to us

Galvanized Steel Products of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords