Hot-Dip Galvanized Steel Coil Used for Industry with No.1 Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

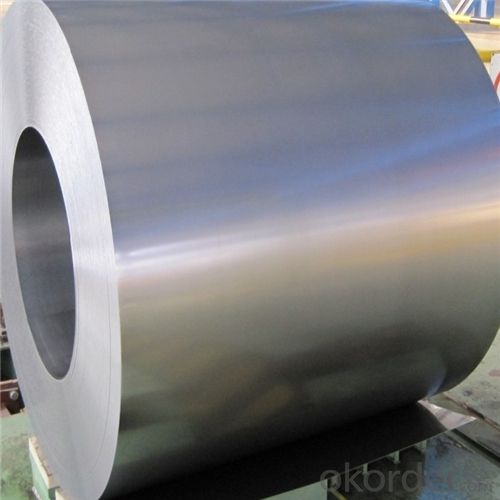

Hot-Dip Galvanized Steel Coil Used for Industry

1.Structure of Hot-Dip Galvanized Steel Coil Description

The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful countless outdoor and industrial applications.

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

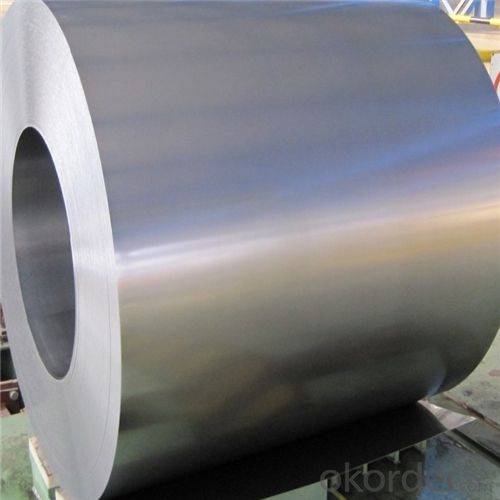

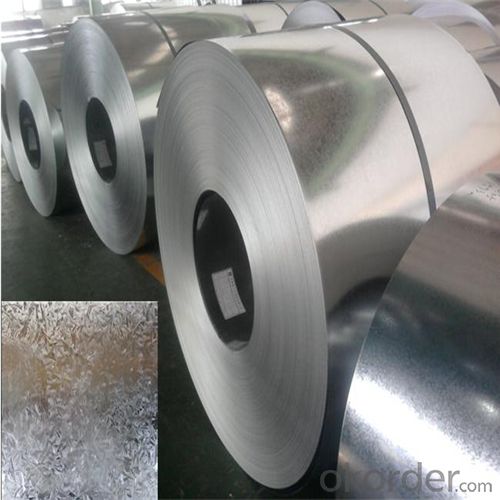

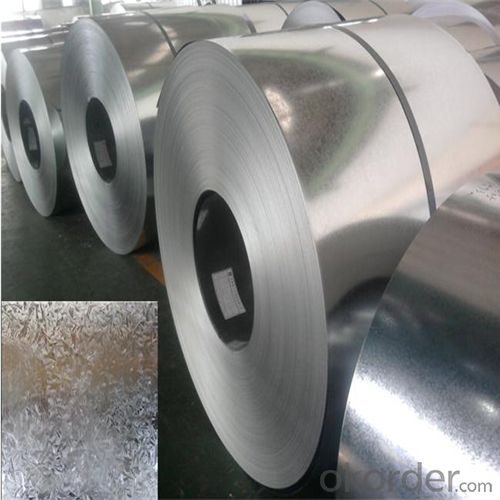

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the different types of steel coil surface coatings?

- There are several different types of steel coil surface coatings, including galvanized steel coatings, aluminized steel coatings, and organic coatings.

- Q: Are steel buildings or homes better then wooden buildings? Why?

- Steel is better than wood. Steel can support more weight than wood. Steel is also much more durable than wood. Termites and rot are not a problem, which results in lower maintenance cost later. Also, wood can rot and warp whereas steel will not. Steel is also more economical than wood. The construction requires less labor, and as a result the labor cost is much lower. Steel is fire resistant, which will lower insurance costs.

- Q: Explain how you could make plastic sink and steel float?

- you can use the steel to make a hollow box, or a ship. There are thousands of steel ships floating in the oceans. plastic, specific gravity ranges from 0.6 to 2, so the higher density ones will sink. Here are some that will sink: Nylon (Polyamide) 1.15 g/mL Plexiglass (Polymethylmethacrylate or PMMA) 1.19 g/mL Lexan (Polycarbonate) 1.2 g/mL PVC (Polyvinyl chloride) 1.16-1.38 g/mL PETE (Polyethylene terephthalate) 1.38-1.39 g/mL .

- Q: How are steel coils used in the shipbuilding industry?

- Steel coils are used in the shipbuilding industry primarily for the construction of ship hulls, decks, and other structural components. These coils are typically processed and shaped into plates, beams, and other forms to provide strength and stability to the ship's structure. The high tensile strength and durability of steel make it an ideal material for shipbuilding, ensuring the vessel's ability to withstand harsh marine environments and heavy loads.

- Q: How are steel coils used in the production of metal cabinets?

- Steel coils are used in the production of metal cabinets as they serve as the primary raw material. These coils are unwound and cut into precise lengths, which are then formed, shaped, and welded to create the various components of the cabinet, such as the sides, back, and shelves. The steel coils provide the necessary strength, durability, and rigidity required for the construction of sturdy and long-lasting metal cabinets.

- Q: I want an EDC (Every Day Carry) Knife that:~folds~is non-serrated~has a pocket clip~has a blade length of about 4 in. long~is concealable~urban environment friendly~priced around $50What do you suggest? I am currently thinking on purchasing the Cold Steel 4 inch Zytel Ti-Lite.

- Based okorder /

- Q: Obviously this is an easy question for anyone who works with metal. However, I am currently writing a book and had an idea that had to do with these two metals. Is it possible for gold to be folded into steel while it is being forged? Do 3-metal alloys exist? If this is not possible with current metal-working techniques and technology, what would be needed to make it possible? And finally, what exactly would the mixing of these two yield? A weak metal? A brittle metal? How would it compare to iron or gunmetal? If you have no idea, please offer speculations. Thank you!

- Since steel is already an alloy (iron with other metals or carbon), you're not alloying gold with a a metal per se. It is possible, though, to alloy gold with steel. However, the creation of any alloy has a practical application behind it. For example, gold is alloyed with silver and copper because otherwise, the gold is too soft to stand up to the use it is intended for and needs to be hardened.

- Q: How are steel coils used in the manufacturing of automotive exhaust systems?

- Steel coils are used in the manufacturing of automotive exhaust systems as they are formed into specific shapes and sizes to create the necessary components, such as pipes, mufflers, and catalytic converters. The coils are precision-cut, welded, and bent to fit the design requirements and ensure efficient exhaust flow, durability, and resistance to high temperatures and corrosion.

- Q: Well actually I was just wondering why people were bashing on stainless so much for katanas. I heard that they don't hold their edge as well as carbon steel blades or Damascus steel. So what makes it so inferior to carbon or other types of steels?

- Stainless steel is not a go0od material for swords. It tends to shatter. There are many stories about people that have been severely injured or killed because a stainless steel sword shattered. It is simply not worth the risk. ...

Send your message to us

Hot-Dip Galvanized Steel Coil Used for Industry with No.1 Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords