Hot-Dip Galvanized Steel Sheet of Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Good formability

• Smooth and flat surface

• Good visual effect

• Excellent anticorrosive property

• Workability, durability

• High strength

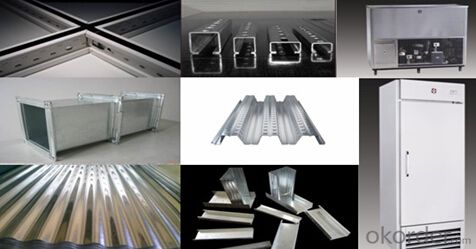

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q: What are the benefits of using coated steel coils in roofing applications?

- Using coated steel coils in roofing applications offers several advantages. Firstly, the steel coils are highly durable and provide excellent resistance against corrosion. The coatings act as a barrier, protecting the metal from moisture, chemicals, and harsh weather conditions. This ensures that the roofing system remains intact and functional for a long time, reducing the need for frequent repairs or replacements. Secondly, coated steel coils offer superior strength and structural integrity. Steel is known for its high tensile strength, and when combined with the protective coating, it becomes even more resilient. This makes coated steel coils an ideal choice for roofing applications, as they can withstand heavy loads, extreme temperatures, and strong winds without compromising the structure's integrity. Additionally, coated steel coils are lightweight, making them easy to handle and install. This saves time and effort during the roofing process and reduces the overall weight of the structure, minimizing stress on the building's foundation. Furthermore, coated steel coils come in a variety of colors and finishes, allowing for greater design flexibility. Architects and homeowners can choose from a wide range of options to enhance the building's aesthetics. The coatings also provide enhanced UV resistance, preventing color fading and ensuring the roofing system maintains its appearance over time. Lastly, using coated steel coils in roofing applications is an environmentally friendly choice. Steel is highly recyclable, and the coatings used on the coils can be formulated to be environmentally friendly as well. This reduces the carbon footprint associated with construction and promotes sustainability. In conclusion, the benefits of using coated steel coils in roofing applications include durability, strength, lightweight, design flexibility, and environmental sustainability. These advantages make coated steel coils a reliable and cost-effective choice for any roofing project.

- Q: What are the different types of steel coil welding methods?

- There are three main types of steel coil welding methods: continuous welding, spot welding, and seam welding. Continuous welding involves joining the edges of steel coils continuously, creating a seamless weld. Spot welding involves applying a series of localized welds at regular intervals along the coil edges. Seam welding is a combination of continuous and spot welding, where a continuous weld is created by intermittent spot welds.

- Q: I have a carbon steel file that I want to bend in a letter C shape. So, what is the malliable temperature? If it's low, could it be done in a camp fire?

- It's now not rather that rough. You can use your charcoal grill to do it. First construct a colossal fireplace in it after which bury the metal within the coals. It'll simplest take approximately ten minuites or so for the metal to warmth by way of. Then decide on it out of the coals with tongs and drop it right into a bucket of water. Repeat as preferred. Eventually it is going to get as brittle as glass. To repair this, you have got to anneal the steel. Again warmth the steel within the coals, simplest this time allow it keep there till the coals cross the entire manner out all by way of themselves. Next day while the entire manner cool, Take it out and blank it off. Viola!, you may have hardened metal.

- Q: How do steel coils resist corrosion?

- A combination of factors contributes to the corrosion resistance of steel coils, including the presence of protective coatings, the utilization of corrosion-resistant alloys, and the implementation of proper handling and storage practices. Galvanization, which involves the application of zinc coatings, is the most common method employed to prevent corrosion in steel coils. This process establishes a barrier between the steel and its surroundings, effectively shielding it from moisture and corrosive elements. The zinc coating acts as a sacrificial layer, taking the brunt of the corrosion instead of the steel itself. Another approach to enhance corrosion resistance entails the use of corrosion-resistant alloys. These alloys are specifically designed to endure harsh conditions and are composed of elements like chromium, nickel, or molybdenum. Upon exposure to the environment, these alloys form a passive oxide layer on the surface of the steel, serving as a protective shield against corrosion. In addition, proper handling and storage practices are crucial in preventing corrosion. It is important to store steel coils in dry and well-ventilated areas to minimize contact with moisture. Care must also be taken to avoid contact with other metals and materials that could result in galvanic corrosion. Regular inspections and maintenance are essential for promptly identifying and addressing any signs of corrosion. In conclusion, the resistance of steel coils to corrosion is achieved through the implementation of protective coatings, the utilization of corrosion-resistant alloys, and the application of proper handling and storage practices. By employing these measures, the longevity and durability of steel coils are ensured in diverse environments.

- Q: What are the dimensions of steel coils used in shipbuilding?

- The shipbuilding industry employs steel coils of varying dimensions, tailor-made to suit the specific needs and construction of each ship. Generally, steel coils utilized in shipbuilding range from 1.5mm to 25mm in thickness and 600mm to 2000mm in width. Additionally, the length of these coils can vary from 1000mm to 6000mm. These dimensions are meticulously selected to guarantee the ship's structure possesses the necessary strength and durability. Simultaneously, weight, flexibility, and ease of handling during the construction process are also taken into consideration.

- Q: What are the characteristics of hot-rolled steel coils and cold rolled steel coils? What loading and unloading tools should be used? What items should be paid attention to?

- General handling steel rolls are used for driving. Forklift trucks are OK, but a larger fork truck, usually cold rolled, weighs less than 15T. The hot rolled coil is below 30T.

- Q: How are steel coils used in the manufacturing of automotive accessories?

- Due to their strength, durability, and versatility, steel coils find widespread use in the manufacturing of automotive accessories. These coils act as the primary raw material for various components and parts utilized in the automotive industry. One notable application of steel coils in automotive accessory production involves the creation of body panels and frames. These coils are shaped and formed according to desired specifications, and subsequently undergo cutting, stamping, and welding processes to fabricate the body panels and frames of vehicles. The exceptional strength of steel coils ensures that the resulting body panels and frames possess the necessary robustness to endure daily use and provide structural integrity to the vehicles. Moreover, steel coils are also employed in the production of automotive suspension systems. Specifically, coil springs, which constitute integral elements of the suspension system, are commonly fashioned from steel coils due to their capability to absorb and distribute the weight and impact of the vehicle. By supplying essential support and shock absorption, these coil springs contribute to a smooth and comfortable ride. Furthermore, steel coils are utilized in the manufacturing of various automotive accessories like exhaust systems, brackets, and other components. These coils are shaped and formed into the desired designs, and subsequently undergo cutting, bending, and welding procedures to fabricate these accessories. The strength and durability of steel render these accessories capable of withstanding high temperatures, vibrations, and other harsh operating conditions. In conclusion, the utilization of steel coils plays a pivotal role in the manufacturing of automotive accessories. Their provision of necessary strength, durability, and versatility facilitates the production of various components and parts. From body panels to suspension systems and accessories, steel coils significantly contribute to the overall quality, performance, and safety of automotive accessories.

- Q: Are steel coils recyclable?

- Yes, steel coils are recyclable. Steel is one of the most commonly recycled materials in the world. Coils made of steel can be easily melted down and used to produce new steel products, making them a valuable resource for recycling.

- Q: I need to know the density of steel as one of my physical properties of steel. Any answers? If u have more physical or chemical properties of steel, that would help to thanks.

- The short answer to your question is that the density of plain mild steel is 7.85. The long answer is that depending on where you look, or the grade of steel that you are talking about can change this value. A density of 7.88 is often quoted for mild steel as well. If you add alloying elements such as tungsten, chrome or manganese to improve the steel, the density will change. So the long answer is that the density of steel can vary between 7.75 and 8.05.

- Q: How are steel coils used in the manufacturing of HVAC systems?

- Steel coils are used in the manufacturing of HVAC systems primarily for heat transfer purposes. They are typically used in air conditioning and refrigeration systems to facilitate the transfer of heat between the refrigerant and the surrounding air. The coils, usually made of copper or aluminum tubes with steel fins, are designed to maximize the surface area available for heat exchange, allowing for efficient cooling or heating of the air passing through the system.

Send your message to us

Hot-Dip Galvanized Steel Sheet of Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords