Galvanized Razor Barbed Wire Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Razor Barbed Wire

1. Product description

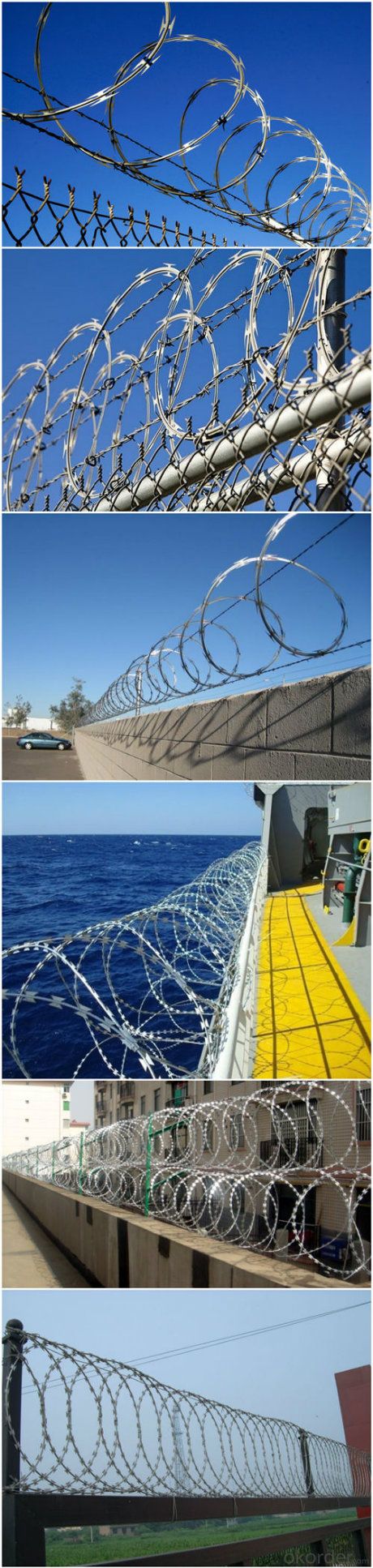

Razor barbed wire is a high security fence system, designed to prevent intrusion along perimeter barriers, it is always fabricated from galvanized or s.s. and high tensile wire.

| Razor barbed wire information | |

| Product name | Razor barbed wire/ Razor wire |

| Country of origin | Anping county, Hebei province, China |

| Application | Military, Prison, School etc |

| Material | Galvanized or S.S. wire |

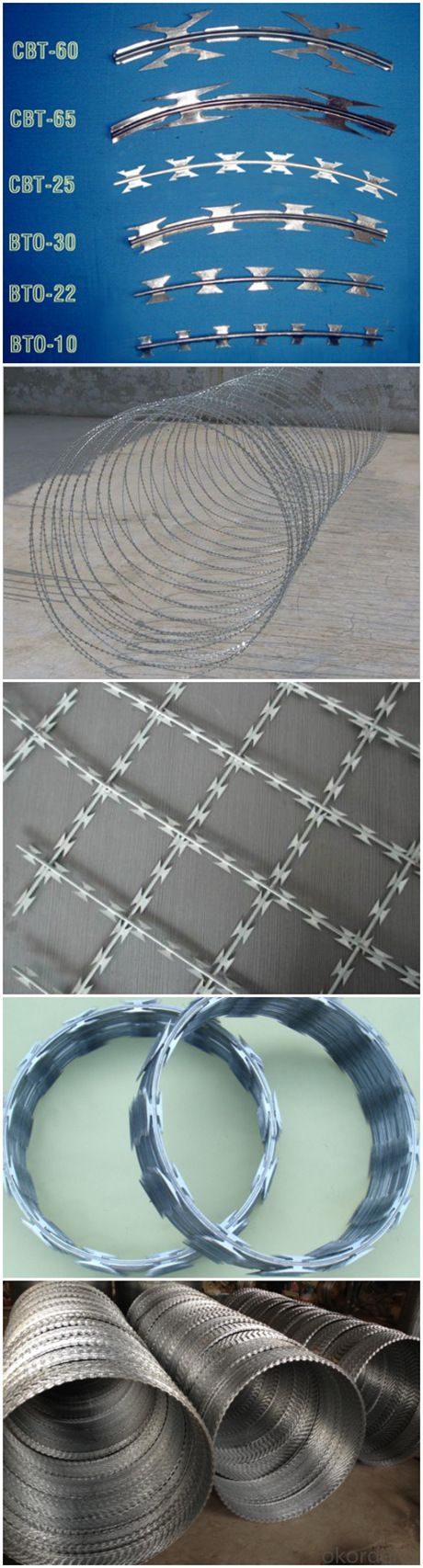

| Type | BTO, CBT |

| Razor thickness | 0.5 ± 0.05mm |

| Diameter | 2.5mm |

| Razor length | 10mm, 12mm, 18mm, 22mm, 30mm |

| Razor width | 13mm, 15mm, 18mm |

| MOQ | 3 Ton |

| Certificat | ISO9001, SGS |

| Packing | Pallets, Carton |

| Delivery time | 10-15 days after deposit |

| Shipping | By sea for bulk order By air/express for small order or samples |

| Payment | T/T, L/C, Western union |

| Express | DHL, TNT, UPS, FEDEX, EMS |

| Remark | Free samples could be supplied Customer order available |

2. Specifications:

| Razor type | Razor thickness (mm) | Wire diameter | Razor length | Razor width | Razor space |

| BTO-10 | 0.5 ±0.05 | 2.5 ± 0.1 | 10 ±1 | 13 ± 1 | 26 ± 1 |

| BTO-12 | 0.5 ±0.05 | 2.5 ± 0.1 | 12±1 | 15 ± 1 | 26 ± 1 |

| BTO-18 | 0.5 ±0.05 | 2.5 ± 0.1 | 18 ±1 | 15 ± 1 | 33 ± 1 |

| BTO-22 | 0.5 ±0.05 | 2.5 ± 0.1 | 22 ±1 | 15 ± 1 | 34 ± 1 |

| BTO-28 | 0.5 ±0.05 | 2.5 ± 0.1 | 28 | 15 | 45 ± 1 |

| BTO-30 | 0.5 ±0.05 | 2.5 ± 0.1 | 30 | 18 | 45 ± 1 |

| BTO-60 | 0.6 ±0.05 | 2.5 ± 0.1 | 60 ±2 | 32 ± 1 | 100 ± 2 |

| BTO-65 | 0.6 ±0.05 | 2.5 ± 0.1 | 65 ±2 | 21 ± 1 | 100 ± 2 |

Ex. Dia. | No. of Turns | Standard Covering Length | Production Model | Remarks |

450mm | 33 | 8M | CBT-65 | Single coil |

500mm | 41 | 10M | CBT-65 | Single coil |

700mm | 41 | 10M | CBT-65 | Single coil |

960mm | 53 | 13M | CBT-65 | Single coil |

500mm | 102 | 16M | BTO-12.18.22 | Cross type |

600mm | 86 | 14M | BTO-12.18.22 | Cross type |

700mm | 72 | 12M | BTO-12.18.22 | Cross type |

800mm | 64 | 10M | BTO-12.18.22 | Cross type |

960mm | 52 | 9M | BTO-12.18.22 | Cross type |

3. Pictures showing:

1) Zhuoda Razor Barbed Wire type and packing

2) Application outside

- Q: while changing a lighting fixture i accidently pulled out the white wire while trying to strip it of the three caps in the electrical box im not sure which one it goes intheres a cap with two black wires and one white running too it another cap with three white wire running two it and a cap with a black wire running too it and the other black wire goes too the fixture which one of these caps do the white wire that connects too the fixture belong in?

- Your fixture is wired as a switch loop. Power comes in at the ceiling box and continues onto other parts of the circuit from there as well. One of the pairs of wires is for the switch. The cable containing the black wire that went to the fixture also contains the white wire that is HOT and is connected to the remaining black wires. All the remaining white wires are neutral and need to be connected together with a wirenut. But before connecting them, also include a white 14-gauge pigtail with the connection. Use a beige or red wirenut. Yellow will be too small. After you've made the wiring connections, simply connect that white pigtail to the white wire of the fixture, and the black wire to the black.

- Q: 2 wires and ground to oven with 3 wires and ground

- Regarding the cooktop: It has NO 120 v component, no timer, electronic controls, etc. Again it has a red, black, and bare ground in the whip. I have also looked around at a number of models like this and none requires anything more than 40 amp circuit and 8 gauge wire. Regarding the double oven: It has some 120 V components, a timer, electronic controls, and lights (it is a pretty modern system). I also downloaded the manual for this model from Maytag's site and it indicates that 8-gauge wire should be used, but the drawings only indicate a 4-wire whip. I triple-checked again tonight and I can only find the 3 wires - red, black, and white. I couldn't pull the ovens out as we were working on the floors. I can do that later. So I am wondering what to do. I can try to call Maytag and see if someone can help me. However, the manual has confused me - perhaps it is for a more recent version of this particular model double oven. Then manual also says If codes permit and a separate ground wire is used, it is recommended that a qualified electrical installer determine that the ground path and the wire gauge are in accordance with local codes. Check with a qualified electrical installer if you are not sure the oven is properly grounded. This oven must be connected to a grounded metal, permanent wiring system. Manual also says 40 am service - 8 gauge wire required.

- Q: I know that a fuse is connected to the live wire. And I was wondering; since a fuse and the circuit breaker are similar, would the circuit breaker also be placed so that both terminals of the circuit breaker are connected to the live wire? If not, would it be connected to a wire that connects a live wire and neutral wire?

- The neutral wire is never connected to to a circuit breaker or fuse. It measures the current passing through the hot wire and opens if the current gets to high. Although the same amount of current passes through the neutral wire, an open breaker or fuse in that wire would let the load be connected to the hot wire but not to ground so you could bet shocked from it.

- Q: how we can predict the maximum load that stainless steel cable wire can achieved?

- The maker should know the load factor of all its cables. It is not easy to know without knowing the wxact formula for the steel, the number and size of wires and how it is wound. You can come up with an estimate based on past knoledge of cable and their performances. Ask the maker

- Q: The switches for the ventilation have 6 wires coming out of the ceiling. My ventilation unit has 5 wires. The ceiling has 2 black, 2 red, and 2 white wires. The ventilation unit has yellow, black, white, red, and blue. how do i make the connections?

- First of all, I agree with Peter K, and you must get those instructions--Very Important! How a fixture is wired depends upon its location in relation to the wires that lead from the main service entrance. So really no one can tell you for sure how to wire your ventilation fixture up without Seeing it. Also, how many switches are involved..1,or 2 or 3? Usually, White wires are always neutral, black always hot. BUT- in certain switch installations both black and white wires could be hot too. Red wires are used for grounding. Now there are improved grounding systems for greater safety, other colors involved, and jumper wires that are connected to the receptacle for a continuous ground. So that is why every one has answered your Q with caution about telling you how to do it. Sorry, I wasn't much of a help either!

- Q: I have 2 wires that go from the Solenoid to the wiring harness. But i don't know which wires go to where. One of the wires from the Solenoid it the remote switch and the other is the power for my whole interior. There are red, orange and black wires that come from the wiring harness. but i don't know which ones to use.

- Your looking for a drive ,but if you would like to look for a starter try Competition Sales online.They deal with mostly Chevy performance parts. Good luck

- Q: Okay, magnet wire is coated with some red fancy insulation. Is that just an enamel?If so, enamel coated copper wire magnet wire would be the same thing.I want to build a loudspeaker. This what I need?Are the coils used in loudspeakers the same ones used in inductor coils?One interesting question,When Faraday was experimenting with the effects of magnetism on electricity, how in the hell did he figure out the magnetic field increased with the number of turns of copper in his coils!I'm only assuming Faraday didn't have insulated copper wires.Lmao, if they aren't insulated, how in the heck is he suppose to know how much the field is increased. The Coil would just become a big conductor lol

- Today we always use magnet wire from inductors, transformers and speaker, but Faraday didn't have any so he just used insulated wire. He was smarter the you and me, so if we know you need insulated wire, so did he.

- Q: What happens when you hook these 2 wires up right along each other?

- if you have an rca tv which works with 12 volts.......if the wires not connected to battery...there no problem. if connected to battery....the fuse blows.(close to battery on wire)....if there is no fuse....wires burn...risk of fire....do not forget...every device works with car battery MUST and MUST be eouipped fuse .

- Q: I have a 2 wire system in my garage and need to update to a 3 wire grounded plug. Can I leave my existed 2 conductor and just run a single 12 gauge insulated ground in the same conduit back to the panel/grounding rod. Or do I need to pull out the 2 wore replace with 3 wire ?

- It will could be tough to pull if there are existing wires in there. You may need to tie a line to what you remove, then lube a new set of wires, and pull the new line and wire back through.

- Q: We bought a used 2004 Chevy Venture that is a cargo style van... it only had a radio in it. So we just bought a Sony car stereo with a cd player to install in it. However, we are having trouble locating the correct wiring harness for the 2004 Venture. We've bought two already for GM vehicles that should technically work for the year of our van, but they do not work. One salesman told us we needed a very expensive wiring harness because it controls the airbags and other electrical gadgets (but they didn't sell it at his store... he said to look online). I've looked online and can't find anything. Would we be better hardwiring it OR does anyone have any experience with a situation like this? Thanks!

- You have to remove the trim plate on the front which involves a few other trim panels like the center trim piece to be removed. Then you can access the IPC screws

Send your message to us

Galvanized Razor Barbed Wire Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches