Galvanized Steel Sheet Price,Silicon Steel Sheet of Transformer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Steel Sheet Price,Silicon Steel Sheet of Transformer

Quick Details

| Standard: | AISI, ASTM, BS, DIN, GB, JIS | Grade: | steel sheet, SGCC, DX51D, Q195, Q215, Q235, Q345 | Thickness: | 0.3-115mm |

| Place of Origin: | Tianjin, China (Mainland) | Brand Name: | hot dipped galvanized steel sheet | Model Number: | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430 ect |

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Galvanized |

| Application: | truck frames, brackets, crane booms,shipbuilding industry | Special Use: | High-strength Steel Plate | Width: | 1000-2000mm |

| Length: | 2000-6000mm or as your requirements | name: | galvanized steel sheet | MOQ: | 25T |

| Certification: | ISO9001:2008 |

Packaging & Delivery

| Packaging Details: | silicon steel sheet of transformer:Standard export seaworthy package. |

| Delivery Detail: | 15-20 days after receiving your deposit or L/C |

Specification

Thickness | 0.3 mm-115mm |

Width | 1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm as customer request |

Length | 2000mm-6000mmor as customer request |

Standard | AISI, ASTM, BS, GB, DIN, JIS, etc |

Material | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430, etc |

Surface | Coated(2B, BA, 8K, No. 4 No.1) Galvanized or bare |

Packaging | Standard export sea-worthy packing |

Technique | Hot rolled / cold rolled |

Delivery time | 10-25days |

Supply ability | 3,0000MT per month |

Payment terms | L/C, T/T, D/P |

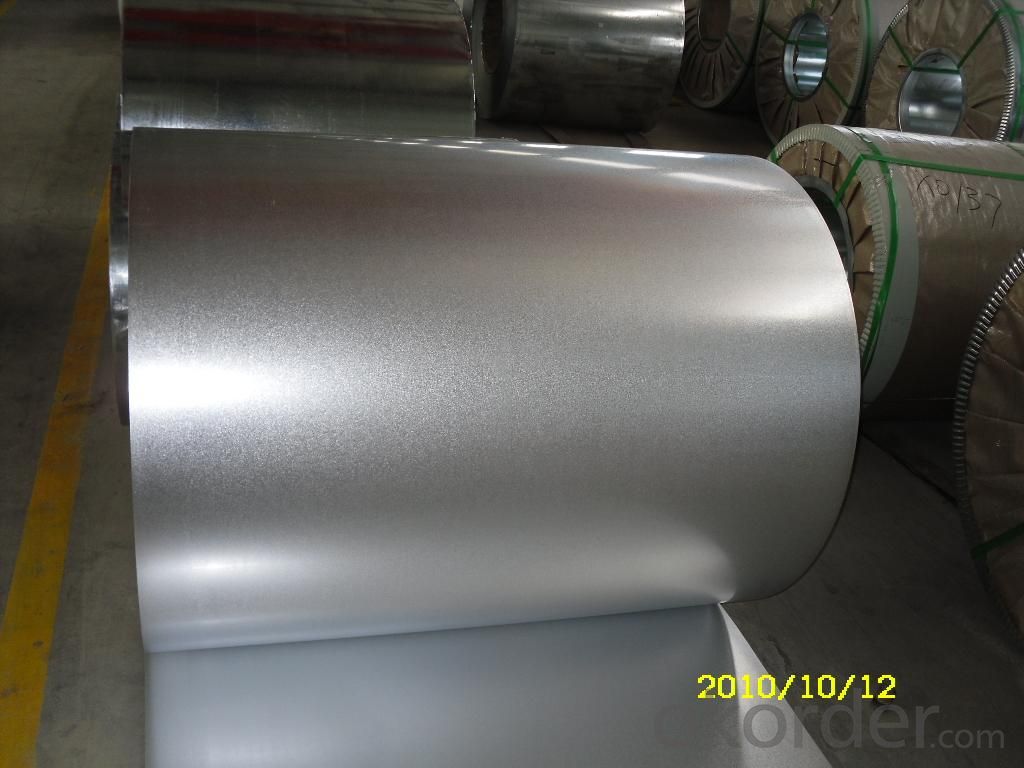

Picture

- Q: Can steel sheets be used for manufacturing jewelry?

- Yes, steel sheets can be used for manufacturing jewelry, particularly for creating durable and unique pieces. However, steel sheets are less commonly used compared to other materials like gold, silver, or platinum, which are more popular in jewelry making due to their aesthetic appeal and higher value.

- Q: Can Q460C steel plate be used as Q235 steel plate?

- Q460C steel plate is superior to Q235 steel in mechanical performance, but Q235 steel plate has lower cost. Therefore, the steel sheet of Q460C material can be used as a Q235 steel plate without considering the cost.

- Q: Are the steel sheets suitable for high-temperature applications?

- Yes, steel sheets are generally suitable for high-temperature applications. Steel is known for its excellent strength and durability, making it a popular choice for various industries requiring materials that can withstand high temperatures. Steel sheets can be manufactured to have high melting points and can retain their structural integrity even under extreme heat. Additionally, steel has good thermal conductivity, allowing it to efficiently transfer heat away from the surface. However, it is important to consider the specific grade and composition of the steel sheets as some alloys are specifically designed for high-temperature applications. It is recommended to consult with a materials engineer or specialist to ensure that the steel sheets selected are suitable for the specific high-temperature environment.

- Q: Are the steel sheets available in different grades?

- Yes, steel sheets are available in different grades.

- Q: What is the typical price range for steel sheets?

- The typical price range for steel sheets can vary depending on several factors such as the type and grade of steel, the thickness and size of the sheets, and the current market conditions. Generally, steel sheets can range in price from around $30 to $200 per sheet. However, it's important to note that these prices are approximate and can fluctuate significantly. It is always recommended to check with local suppliers or manufacturers to get the most accurate and up-to-date pricing information for steel sheets.

- Q: What is the average moisture resistance of steel sheets?

- The average moisture resistance of steel sheets can vary depending on the specific type of steel and the protective coatings applied. Generally, steel sheets exhibit good moisture resistance due to their inherent ability to resist corrosion. However, additional surface treatments like galvanization can further improve their resistance by adding a layer of zinc to protect against moisture and corrosion. Providing an exact average moisture resistance value is challenging as it depends on factors such as the steel grade, thickness, and coating. Steel sheets with galvanized coatings typically offer excellent moisture resistance, with some studies reporting corrosion rates as low as 0.1-0.5 micrometers per year in highly corrosive environments. It is important to consider that the performance of steel sheets in resisting moisture can also be affected by factors like scratches, cuts, or exposure to chemicals. Proper maintenance, regular inspection, and careful handling of steel sheets are crucial to ensure their optimal moisture resistance over time.

- Q: How are steel sheets priced?

- Steel sheets are typically priced based on factors such as the type and grade of steel used, the size and thickness of the sheet, market demand and supply, and any additional processing or finishing required.

- Q: Are steel sheets resistant to radiation?

- Yes, steel sheets are generally resistant to radiation due to their high density and composition. The thickness and quality of the steel can influence its resistance, but in general, steel sheets provide a protective barrier against radiation.

- Q: How do steel sheets perform in low-temperature environments?

- In low-temperature environments, steel sheets typically demonstrate excellent performance. The presence of low temperatures does not significantly impact the mechanical properties of steel, such as its strength and toughness. Steel possesses a low coefficient of thermal expansion, which means it does not undergo significant contraction or expansion when exposed to temperature fluctuations. This characteristic enables steel sheets to maintain their shape and structural integrity even in cold conditions. Furthermore, steel exhibits remarkable resistance to brittle fracture at low temperatures. It possesses excellent impact resistance, allowing it to absorb energy without fracturing. As a result, steel sheets are suitable for use in low-temperature environments where materials must endure heavy loads or sudden impacts, such as in cold storage facilities or offshore structures in Arctic regions. It is important to note, however, that certain types of steel, particularly those with high carbon content or low alloy steels, may experience reduced toughness and ductility at extremely low temperatures. In such cases, specific precautions may be necessary. These precautions may include utilizing steel grades specially designed for low-temperature applications or implementing appropriate insulation measures to prevent rapid temperature changes. Overall, steel sheets are generally dependable and exhibit excellent performance in low-temperature environments due to their strength, toughness, and resistance to brittle fracture. Nevertheless, the precise performance of steel in cold conditions may vary depending on the composition and quality of the steel employed.

- Q: Are steel sheets suitable for exterior cladding?

- Yes, steel sheets are suitable for exterior cladding. They are durable, weather-resistant, and provide a sleek and modern appearance to buildings. Additionally, steel sheets offer great strength and can withstand harsh environmental conditions, making them a reliable choice for exterior applications.

Send your message to us

Galvanized Steel Sheet Price,Silicon Steel Sheet of Transformer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords