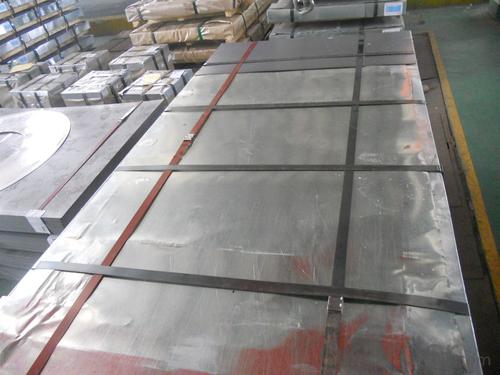

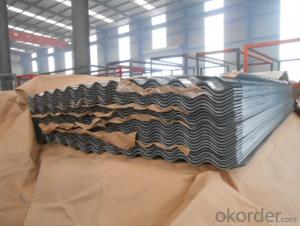

Hot-Dip Galvanized Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commodity | Hot dip galvanized steel coil and sheet |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143 |

Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

Length | 2000/2448/2800/3000/5000mm |

Thickness | 0.12-2.8mm |

Type of coating: | Galvanized |

Zinc coating | Z30-275g/m2 |

Surface Treatment | Chromed / Skin-pass/ Oiled/Slightly Oiled/ Dry/ Anti-fingerprint |

Surface structure: | Zero spangle / minimized spangle / regular spangle/ big spangle |

ID coil | 508mm or 610mm |

Coil weight | 3-8 MT per coil |

Package: | Properly packed for ocean freight exportation in 20''containers |

Application: | Industrial panels, roofing and siding for painting |

Price terms | FOB,CFR,CIF |

Payment terms | T/T or L/C |

Delivery time | Within 30 days |

Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certification test,such as SGS/BV |

Technicaldata :

Hot dipped galvanized coil Technical Data

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

|

|

|

|

|

| |

Hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: What is the typical thickness tolerance of a steel sheet?

- Depending on the specific industry and application requirements, the thickness tolerance of a steel sheet can vary. In general, a standard steel sheet may have a thickness tolerance ranging from +/- 0.001 inches to +/- 0.010 inches. This implies that the actual thickness of the sheet can fall within these tolerances. The determination of the tolerance level is influenced by factors including the manufacturing process, the intended use of the sheet, and the desired level of precision. It is worth mentioning that certain industries or applications may necessitate more precise tolerances, particularly when dimensional accuracy is of utmost importance.

- Q: How do you prevent galvanic corrosion when using steel sheets in contact with water?

- To prevent galvanic corrosion when using steel sheets in contact with water, you can employ several measures. One effective approach is to apply a protective coating or paint on the steel sheets, acting as a barrier between the steel and water. Another option is to use corrosion-resistant steel alloys, such as stainless steel, which have inherent resistance to galvanic corrosion. Additionally, isolating the steel sheets from other dissimilar metals or using corrosion inhibitors can help prevent galvanic corrosion. Regular inspection, maintenance, and prompt repair of any coating damages are also crucial to avoid the onset of corrosion.

- Q: Can steel sheets withstand extreme temperatures?

- Yes, steel sheets can withstand extreme temperatures. Steel is known for its high melting point, which is around 1370°C (2500°F). This makes it suitable for use in environments with extreme heat, such as furnaces, kilns, and industrial ovens. Additionally, steel has excellent thermal conductivity, allowing it to efficiently transfer heat and resist thermal expansion and contraction. These properties make steel sheets resistant to warping, cracking, and other forms of structural damage that can occur under extreme temperature conditions.

- Q: Can the steel sheets withstand extreme temperatures?

- Yes, steel sheets are designed to withstand extreme temperatures and maintain their structural integrity.

- Q: What is the typical lifespan of painted steel sheets?

- The typical lifespan of painted steel sheets can vary depending on various factors such as the quality of the paint, the environment in which they are exposed, and the maintenance provided. However, on average, painted steel sheets can last anywhere from 20 to 30 years before they may require repainting or replacement.

- Q: Can steel sheets be used in agricultural applications?

- Yes, steel sheets can be used in agricultural applications. They are commonly used for building structures like barns, sheds, and storage buildings due to their durability, strength, and resistance to harsh weather conditions. Steel sheets can also be used for fencing, roofing, and as a lining material for troughs and silos.

- Q: How are steel sheets measured and classified?

- Steel sheets are typically measured and classified based on their thickness, which is measured in gauge or millimeters. The classification of steel sheets is also determined by their specific grade, composition, and intended application.

- Q: What is the weight of a typical steel sheet?

- The dimensions and thickness of a steel sheet can cause fluctuations in its weight. Nevertheless, for a rough approximation, a commonly employed steel sheet in construction and manufacturing, measuring 4' x 8', usually weighs approximately 80 to 100 pounds (36 to 45 kilograms). It is crucial to acknowledge that this weight can vary based on the specific steel type and its gauge or thickness.

- Q: Are the steel sheets suitable for solar panel mounting?

- Yes, steel sheets are suitable for solar panel mounting. They provide strong support and durability, making them an ideal choice for securely mounting solar panels on various surfaces.

- Q: How do you cut steel sheets?

- Steel sheets can be cut through several methods, including using power tools such as plasma cutters, laser cutters, or shearing machines. These tools provide precise and efficient cuts by melting, burning, or shearing through the steel sheet. The choice of method often depends on the thickness and type of steel being cut, as well as the desired precision and speed.

Send your message to us

Hot-Dip Galvanized Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords