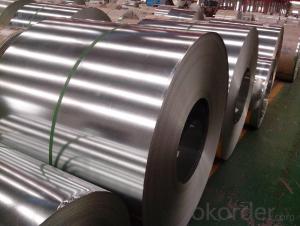

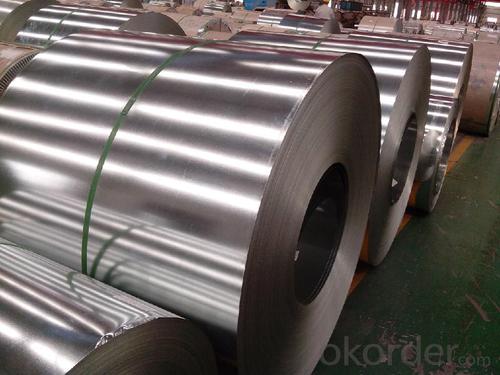

Hot Dip Galvanized Sheet,Gi Sheet,Competitive Galvanized Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time by bulk or container

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time with bulk or container

packing: Mill standard export packing in bundles/coil, around 2tons/bundle.

country of Origin: China

delivery Time: Within a 35 days

Shipment: by bulk vessel or by container

Leading goods:

section steel:angles,channels,I-beam,H-beam;

coils:cold/hot rolled coils,PPGI,galvanized coils,plate,checkered plate,cutting steel plate,steel strip;

wire rod:steel wire,deformed wire,bar;

pipe:seamless pipe,rectangular pipe,welded pipe,spiral welded pipe,pipe fittings;

stainless steel:steel sheets,stainless steel strips,stainless bar,stainless tube;

special:weathering steel,shipbuilding steel;

construction steel:C-channel,Z-channel,T-bar,high-speed divider plate,corrugated steel plate,steel grating.

Advantage:

We are the spot supplier, Six huge warehouses which can hold 20,000 MT goods.

It makes the cost lower than others,we can provide the competitive price for you.

Delivery time:

Normal sizes can be provided in 7days, the others should be ready in 30---45 days.

Further treatment:

We can offer cutting,painting,drilling holes,bending,threading, welding,galvanization,packing etc.

Security interest:

We have already passed the ISO9001, BV and SGS authentication which makes the quality secured.

If you have the interest in any of the products we can provided, pls don't hesitate to connect with me. Looking forward to cooperate with you.

FAQ of Steel Deformed Bar

1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

- Q: Are steel sheets available in different hardness levels?

- Yes, steel sheets are available in different hardness levels.

- Q: What is the bending radius for steel sheets?

- The bending radius of steel sheets is influenced by several factors, including the sheet's thickness, the type of steel utilized, and the particular application at hand. Typically, a widely accepted guideline suggests employing a bending radius that is no less than twice the thickness of the steel sheet. Nevertheless, this figure can fluctuate depending on the specific demands and constraints of the undertaking. It is crucial to seek guidance from engineering and fabrication specialists experienced in handling steel sheets to ascertain the suitable bending radius for a specific application.

- Q: How do steel sheets perform in UV resistance?

- Steel sheets do not have inherent UV resistance. However, the addition of protective coatings or treatments can significantly improve their ability to resist damage from UV radiation.

- Q: Can steel sheets be used for balcony railings?

- Yes, steel sheets can be used for balcony railings. Steel is a sturdy and durable material, making it suitable for railings that require strength and stability. It can also be customized to achieve various designs and styles, enhancing the aesthetic appeal of the balcony.

- Q: What are the functions and classifications of galvanized sheet?

- Transportation industry: car, car, car shell ceiling board, tractor, tram, container, highway fence, ship bulkhead etc.Other instruments shell, trash, billboards, watches, photographic equipment, measuring devices and other color coated steel plate with hot galvanized plate, hot galvanized plate, galvanized plate as the substrate, the surface of galvanized plate type pre processing include: hot galvanized plate, galvanized plate, tinplate, galvanized plate pressing and molding, with connecting hooks, without any accessories can be securely firmly connected mesh columns.Galvanized sheet according to its use can be divided into: activated alumina, galvanized plate, desiccant, galvanized plate and catalyst galvanized sheet. The inner cavity of the working room is made of high quality galvanized or stainless steel plate to make it rustproof and clean;

- Q: Are the steel sheets susceptible to rusting?

- Certainly, steel sheets can be prone to rusting. Rust forms due to the chemical reaction involving iron, oxygen, and moisture. Given that steel is mostly composed of iron, it can readily corrode upon contact with air and water. Nevertheless, the degree of rusting varies based on factors like the steel type, environmental circumstances, and the availability of protective coatings. To thwart rusting, people frequently apply substances such as zinc or paint onto steel sheets to establish a barrier between the steel surface and its surroundings. Additionally, taking regular care and storing the sheets properly can significantly reduce the likelihood of rust formation.

- Q: What is the average fire rating for steel sheets?

- The average fire rating for steel sheets can vary depending on various factors, such as the thickness of the sheet, the type of steel used, and the specific fire testing standards that are being followed. Typically, steel sheets have a fire rating ranging from 30 minutes to 2 hours. However, it is important to note that fire ratings can be enhanced by incorporating additional fire-resistant materials or by using fire-resistant coatings on the steel sheets. It is always recommended to consult with fire safety experts or refer to the specific fire testing standards to determine the exact fire rating for a particular type of steel sheet.

- Q: Can steel sheets be customized according to specific requirements?

- Yes, steel sheets can be customized according to specific requirements. Steel manufacturers have the capability to produce steel sheets in various sizes, thicknesses, and finishes to meet the specific needs of customers. Customization options also include specific alloy compositions, surface treatments, and mechanical properties. Through cutting, shearing, bending, and shaping processes, steel sheets can be tailored to fit specific dimensions and shapes required for various applications. Additionally, manufacturers can also provide customized branding, labeling, and packaging options as per the customer's requirements. Overall, steel sheets offer a high level of flexibility and can be easily customized to meet specific requirements.

- Q: Can the steel sheets be used for industrial machinery?

- Industrial machinery can indeed utilize steel sheets. Steel, known for its robustness, endurance, and resistance to damage, is a favored option for constructing industrial machinery. By shaping, cutting, and welding steel sheets, manufacturers can produce diverse components and parts essential for industrial machinery. The adaptability of steel empowers manufacturers to design and fabricate machinery that precisely meets specifications and demands. Furthermore, steel's capacity to endure hefty burdens, extreme temperatures, and corrosive surroundings renders it suitable for a vast array of industrial applications.

- Q: Are the steel sheets suitable for solar panel mounting?

- Yes, steel sheets are suitable for solar panel mounting. They provide strong support and durability, making them an ideal choice for securely mounting solar panels on various surfaces.

Send your message to us

Hot Dip Galvanized Sheet,Gi Sheet,Competitive Galvanized Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords