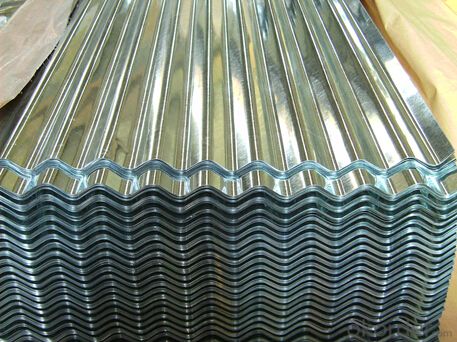

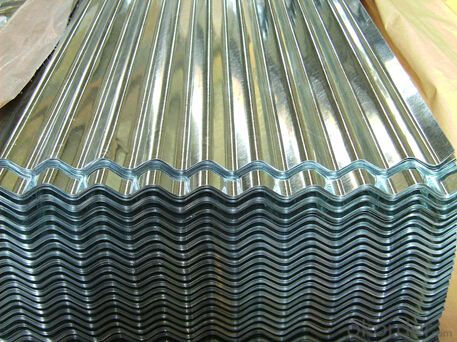

galvanized corrugated steel sheet high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q: Can steel sheets be used for heat transfer applications?

- Yes, steel sheets can be used for heat transfer applications due to their high thermal conductivity and ability to withstand high temperatures. They are commonly used in various industries, such as HVAC systems, automotive manufacturing, and power generation, for efficient heat transfer and dissipation.

- Q: What are the maintenance requirements for steel sheets?

- The maintenance requirements for steel sheets typically involve regular cleaning to remove dirt, dust, and other debris. Additionally, applying a protective coating such as paint or galvanization can help prevent corrosion and rust. Inspecting for any signs of damage or wear is also important, and any issues should be addressed promptly to maintain the integrity and longevity of the steel sheets.

- Q: Can steel sheets be used in medical applications?

- Yes, steel sheets can be used in medical applications. They are commonly used in the manufacturing of medical instruments, surgical equipment, and medical furniture due to their strength, durability, and corrosion resistance properties.

- Q: What is the process of applying soundproofing materials to steel sheets?

- The process of applying soundproofing materials to steel sheets typically involves cleaning the surface of the steel sheets to remove any dirt or debris. Then, an adhesive or bonding agent is applied to the steel sheets, followed by the soundproofing material, such as acoustic foam or mass-loaded vinyl. The soundproofing material is pressed firmly onto the adhesive to ensure proper adhesion. Depending on the specific application, additional steps such as sealing the edges or using mechanical fasteners may be included.

- Q: How do you transport steel sheets safely?

- To transport steel sheets safely, it is important to use proper equipment such as cranes, forklifts, or specialized trucks that are designed to handle heavy loads. The steel sheets should be securely strapped or clamped to prevent any movement during transportation. Additionally, using protective materials like padding or blankets can help prevent scratches or damage to the steel sheets. Regular inspections of the equipment and ensuring that the weight limits are not exceeded are also crucial for safe transportation.

- Q: What's the corrosion resistance of hot-dip galvanized steel sheet?

- Hot galvanized steel sheet is currently at 7200-7500 yuan per ton304 stainless steel plates are currently at $28000-30000 per ton

- Q: Are steel sheets suitable for bulletproof applications?

- Yes, steel sheets are commonly used in bulletproof applications due to their high strength and durability. They provide excellent protection against bullets, making them suitable for various bulletproof applications such as armored vehicles, body armor, and bulletproof barriers.

- Q: What are the different edge finishes available for steel sheets?

- Depending on the desired aesthetic and functional requirements, steel sheets offer various edge finishes. The most common options are as follows: 1. Mill Edge: Directly from the steel mill, this is the standard and unfinished edge. It is typically used in non-critical applications like industrial or structural use. 2. Trimmed Edge: Irregularities and burrs are removed by trimming or shearing the rough mill edge. This provides a cleaner and more uniform edge, making it suitable for applications where appearance matters. 3. Deburred Edge: Through a deburring process, sharp or jagged edges are eliminated, resulting in a smooth and rounded edge. This enhances safety, making it common in applications involving frequent handling or contact. 4. Beveled Edge: The edge is cut or ground at an angle, creating a sloping or chamfered edge. This improves both aesthetics and functionality, especially in architectural applications and jointing or welding. 5. Rolled Edge: By rolling or bending the steel sheet's edge, a rounded or folded edge is formed. Rolled edges provide a smooth and finished appearance, making them ideal for visible applications like decorative or furniture manufacturing. 6. Hemmed Edge: Folding the edge of the steel sheet over itself creates a double-layered and durable edge resistant to fraying or unraveling. Hemmed edges are commonly used in exposed areas that require added durability, such as roofing or sign manufacturing. These examples demonstrate the range of edge finishes available for steel sheets. Each finish offers unique characteristics and benefits, allowing for customization based on specific requirements and preferences.

- Q: Can steel sheets be used in food processing or pharmaceutical industries?

- Yes, steel sheets can be used in food processing and pharmaceutical industries. Stainless steel sheets are commonly used in these industries due to their excellent corrosion resistance, durability, and hygienic properties. Stainless steel is non-reactive and does not leach any harmful substances into the food or pharmaceutical products. It is also easy to clean and maintain, making it suitable for applications where high levels of cleanliness and hygiene are required. Additionally, stainless steel sheets can withstand extreme temperatures and are resistant to impact and abrasion, making them ideal for use in food processing and pharmaceutical industries where strict quality and safety standards are essential.

- Q: What is the process of cutting steel sheets?

- The process of cutting steel sheets typically involves using specialized tools or machinery such as shears, laser cutters, or plasma cutters to accurately and precisely cut through the steel material. This process may involve marking the desired cut lines, securing the sheet, and then applying the cutting method to achieve the desired shape or size. Safety measures like wearing protective gear and ensuring proper ventilation are necessary during the cutting process.

Send your message to us

galvanized corrugated steel sheet high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords