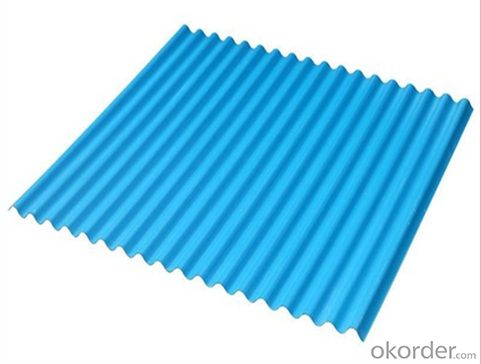

Premium Quality Corrugated Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

Premium Quality Corrugated Galvanized Steel Sheet

Galvanized Corrugated Steel Roofing Sheet is formed by cold roll machine, using galvanized steel sheet or aluminum steel as the base material .Galvanized corrugated steel roofing sheet is featured with easy installation ,high strength ,more economic .(and low cost )

Product Features

.Surface have been treated as galvanized and color coated.so it can anti-rain,anti- fire,anti-quake,So it has a long term life as 20-30 year and color just not fade.

. Light weight: easy to transport the material,short the time to finish the building,reduce worker's hard work,save much time and energy for human beings.

.Smooth surface treatment,the dust will be easy taken off by the rain.

. Environmental material,can be used many times,will do no hard to the our environment.

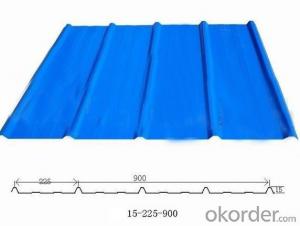

Product Specification

Premium Corrugated GI Galvanized Steel Sheet

Packing Information (For 27.5 Tons heavy 20’Fcl)

. water proof paper packing inside

. plastic film Packing in middle

. steel sheet Packing outside

.several steel strip packing to fix the packing

Production Line & Package

FAQ

1. how many wave for per pcs

—— some wave is 8 ,same wave is 9 ,save wave is 11 ,it is up to your request

2. What is the MOQ for this products ?

—— Normally the MOQ is 25mt per size and per color .

- Q: How are steel strips tested for hardness?

- Steel strips are typically tested for hardness using a method called the Rockwell hardness test. This involves applying a specific amount of force to the surface of the steel strip using a diamond or carbide ball indenter, and then measuring the depth of the indentation. The hardness value is determined based on the depth of the indentation, providing an accurate measure of the steel strip's hardness.

- Q: How are steel strips packaged and shipped?

- Steel strips are typically packaged and shipped in a way that ensures their safety and protection during transportation. The packaging process involves several steps to secure the steel strips and prevent any damage or deformation. Firstly, the steel strips are carefully rolled and coiled into a tight, compact shape. This helps to minimize the risk of bending or warping during shipping. Once coiled, the steel strips are usually wrapped with a protective layer, such as plastic or paper, to provide an additional barrier against moisture and other external elements. After wrapping, the coiled steel strips are often placed on wooden or steel pallets for easy handling and transportation. The pallets help to distribute the weight evenly and prevent any excessive pressure on the steel strips, reducing the chances of damage. To further secure the steel strips, they are typically bound together with metal or plastic straps. These straps are tightly fastened around the coiled strips to hold them in place and prevent any movement or shifting during transit. Once the steel strips are properly packaged, they are loaded onto trucks, ships, or other transportation vehicles for shipping to their destination. During transportation, it is crucial to handle the packages with care and ensure they are properly secured to prevent any accidents or damage. Overall, steel strips are packaged and shipped in a way that prioritizes their safety and protection. The packaging process involves rolling, wrapping, palletizing, and strapping to secure the steel strips and minimize the risk of damage during transportation.

- Q: What is the length tolerance of steel strips?

- The length tolerance of steel strips varies depending on the specific industry and application requirements. Generally, the length tolerance for steel strips is specified by the manufacturer or customer in terms of a permissible range of deviation from the desired or nominal length. The length tolerance is typically expressed as a plus or minus value, indicating the maximum allowable deviation from the specified length. For example, a length tolerance of +/- 0.5mm means that the actual length of the steel strip can vary by up to 0.5mm in either direction from the desired length. The specific length tolerance for steel strips can be influenced by multiple factors, including the manufacturing process, the intended use of the strips, and the industry standards or regulations that apply. It is important to consult the relevant specifications and guidelines provided by the manufacturer or customer to determine the appropriate length tolerance for a specific application. In some cases, tighter length tolerances may be required for applications where precise dimensions are critical, such as in automotive or aerospace industries. Conversely, less stringent tolerances may be acceptable for applications where exact length is not as critical, such as in construction or general manufacturing. Ultimately, the length tolerance of steel strips is determined by the specific requirements of the application and should be carefully considered to ensure that the strips meet the desired specifications and performance criteria.

- Q: What are the advantages of using steel strips in construction?

- There are several advantages of using steel strips in construction. Firstly, steel strips are incredibly strong and durable, making them ideal for supporting heavy loads and withstanding extreme weather conditions. Additionally, steel strips have a high tensile strength, allowing for longer spans and fewer supporting columns, which can result in cost savings and more flexible design possibilities. Furthermore, steel strips are fire-resistant, reducing the risk of structural damage in case of a fire. Lastly, steel strips are recyclable, making them an environmentally friendly choice for construction projects.

- Q: How do steel strips withstand corrosion?

- Steel strips withstand corrosion through a process called corrosion resistance. This is achieved by applying a protective coating, such as zinc or chromium, to the surface of the steel strips. These coatings act as a barrier, preventing water and oxygen from reaching the steel and causing oxidation. Additionally, the coatings can self-heal minor scratches or damages, further enhancing the corrosion resistance of the steel strips.

- Q: How are steel strips used in the production of metal nameplates?

- Steel strips are used in the production of metal nameplates as a base material. They provide the necessary strength and durability for the nameplate, while also allowing for easy customization through processes like engraving, embossing, or painting.

- Q: What are the different surface etching methods for steel strips?

- There are several different surface etching methods that can be used for steel strips, depending on the desired outcome and the specific requirements of the application. Some of the most commonly used methods include: 1. Chemical etching: This is a process where a chemical solution is applied to the surface of the steel strip to remove a thin layer of material. The specific chemical used will depend on the desired effect, such as creating a smooth or matte finish. Acid solutions, such as hydrochloric acid or sulfuric acid, are commonly used for this purpose. 2. Electrochemical etching: This method involves using an electrical current to selectively dissolve the steel surface. The steel strip is immersed in an electrolyte solution, and a direct current is applied to create a controlled etching reaction. This method allows for precise control of the etching process and can be used to create intricate patterns or designs on the steel surface. 3. Laser etching: Laser etching is a non-contact method that uses a high-powered laser beam to selectively remove material from the steel strip. This method is highly precise and can be used to create detailed markings or patterns on the surface. It is often used for branding or identification purposes. 4. Mechanical etching: Mechanical etching involves physically abrading the surface of the steel strip to create the desired texture or finish. This can be done using abrasive materials, such as sandpaper, wire brushes, or grinding wheels. This method is often used to remove scale or other surface imperfections and to create a uniform texture on the steel surface. Each of these surface etching methods has its own advantages and limitations, and the choice of method will depend on factors such as the desired finish, the complexity of the design, and the specific requirements of the application. It is important to carefully consider these factors and consult with experts in the field to determine the most appropriate method for achieving the desired results.

- Q: What are the high speed steel strips and material specifications?

- Cold rolled carbon steel strip is made of high quality carbon structural steel by cold rolling. Because the cold rolled strip can be rolled to a specific heat, the rolling strip is thinner, and has higher dimensional precision and higher strengthCold rolled thin thick hot rolled instead for the same purpose, which can save about 30% steel. According to manufacturing accuracy can be divided into general accuracy (P), width accuracy higher (K), thickness

- Q: What are the different methods for shearing steel strips?

- There exists a variety of approaches to shear steel strips, depending on the specific requirements and desired outcomes. Some of the most frequently employed techniques encompass the following: 1. Traditional and extensively utilized, guillotine shearing involves a guillotine-style machine with a stationary blade and a moving blade that cuts the steel strip in a straight line. 2. Rotary shearing employs a rotary shear to cut the steel strip. This method employs a set of rotating blades that move in a circular motion to accomplish the cutting process swiftly and continuously. 3. Slitting is a method to cut wide steel strips into narrower ones. It entails feeding the steel strip through a set of circular blades that move in opposing directions, thus creating parallel cuts and dividing the strip into multiple narrower ones. Slitting is notably common in metal fabrication, automotive, and packaging industries. 4. Laser cutting, a contemporary and highly precise technique, utilizes a high-powered laser beam to melt or vaporize the material along a predetermined cutting line. Laser cutting offers exceptional accuracy, speed, and versatility, rendering it suitable for a broad range of applications. 5. Waterjet cutting employs a high-pressure stream of water mixed with abrasive materials to cut through steel strips. The waterjet can be directed by computer-controlled mechanisms to follow a specific cutting pattern. This method is renowned for its ability to cut through various thicknesses and materials without generating heat or causing distortion. 6. Electrical discharge machining (EDM) is a non-traditional machining process that can be utilized for shearing steel strips. It entails employing electrical discharges to eliminate material from the workpiece. EDM enables precise and intricate cuts, making it ideal for cutting complex shapes and contours in steel strips. These represent merely a few of the diverse methods accessible for shearing steel strips. The choice of technique hinges upon factors such as the required accuracy, speed, material thickness, and the specific application or industry in which the steel strips are utilized.

- Q: How are steel strips used in the production of metal staircases?

- Steel strips are commonly used in the production of metal staircases as they provide structural support and reinforcement. These strips are typically attached to the staircase framework to enhance its strength and stability. Additionally, they can be used to create the steps themselves, adding durability and longevity to the staircase design.

Send your message to us

Premium Quality Corrugated Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords