Galvanized Corrugated Steel Sheet in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip GI/GL Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip GI/GL Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip GI/GL Steel Sheet Images:

4.Hot-Dip GI/GL Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

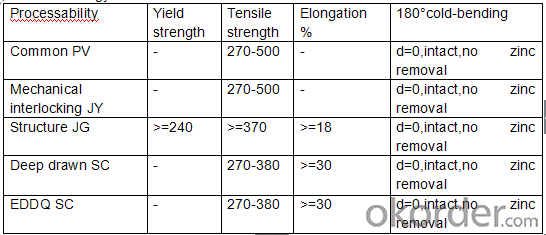

Technology test results:

5.FAQ of Hot-Dip GI/GL Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Can steel sheets be used for interior design purposes?

- Yes, steel sheets can be used for interior design purposes. They are commonly used for creating modern and industrial aesthetics in interior spaces. Steel sheets can be used for various applications such as wall paneling, room dividers, countertops, backsplashes, and decorative accents. Their durability, sleek appearance, and ability to be customized make them a popular choice for contemporary interior designs.

- Q: Can steel sheets be used for electrical transformer cores?

- Yes, steel sheets can be used for electrical transformer cores. Steel is a commonly used material for transformer cores due to its magnetic properties, such as its ability to conduct magnetic flux and minimize energy losses. The laminated steel sheets are stacked together to form the core, providing a low reluctance path for the magnetic field and reducing eddy current losses.

- Q: Are the steel sheets recyclable?

- Yes, steel sheets are recyclable. Steel is one of the most commonly recycled materials worldwide due to its high recycling rate and ease of processing. When steel sheets reach the end of their useful life, they can be collected, sorted, and sent to recycling facilities where they are melted down and transformed into new steel products. Recycling steel sheets not only helps conserve natural resources and reduce energy consumption but also helps reduce waste and minimize environmental impact.

- Q: Are steel sheets suitable for interior partition walls?

- Yes, steel sheets are suitable for interior partition walls. They are strong, durable, and provide excellent fire resistance. Additionally, steel sheets can be easily installed and offer design flexibility, allowing for various finishes and customization options.

- Q: Can steel sheets be used for food processing applications?

- Yes, steel sheets can be used for food processing applications. Stainless steel sheets are commonly used in the food industry due to their corrosion resistance, durability, and ease of cleaning. They are suitable for various food processing equipment, such as conveyor belts, countertops, food storage containers, and cooking surfaces.

- Q: Can steel sheets be used for roofing purposes?

- Yes, steel sheets can be used for roofing purposes. Steel is a durable and long-lasting material that is resistant to corrosion, making it an excellent choice for roofing. Steel sheets provide strength and stability to the roof, protecting the building from various weather conditions. Additionally, steel roofs are low maintenance and can be energy-efficient if properly insulated.

- Q: What is the typical corrosion resistance of a steel sheet?

- The typical corrosion resistance of a steel sheet can vary depending on factors such as the specific type of steel, the presence of protective coatings, and the environment in which it is exposed. However, steel sheets are generally known for their moderate to high corrosion resistance due to the presence of alloying elements such as chromium and nickel.

- Q: Do steel sheets require any special maintenance?

- Yes, steel sheets require some special maintenance to ensure their longevity and performance. Regular inspection and cleaning are necessary to prevent the build-up of dirt, debris, and corrosion. Additionally, applying protective coatings or paint can help to protect the steel from rust and other damages. Proper storage and handling, such as avoiding exposure to moisture and extreme temperatures, are also important to maintain the quality of steel sheets.

- Q: Can steel sheets be used for manufacturing electrical enclosures?

- Yes, steel sheets can be used for manufacturing electrical enclosures. Steel is a commonly used material for constructing electrical enclosures due to its durability, strength, and ability to provide necessary protection for electrical components. The use of steel sheets ensures that the enclosure is sturdy and can withstand various environmental conditions. Additionally, steel offers good electromagnetic shielding properties, which can help protect sensitive electronic equipment from interference. Steel sheets are also fire-resistant, making them suitable for manufacturing enclosures that need to meet safety regulations. Overall, steel sheets are a reliable choice for manufacturing electrical enclosures due to their characteristics and suitability for the purpose.

- Q: Can steel sheets be used for architectural purposes?

- Yes, steel sheets can be used for architectural purposes. Steel sheets are versatile and widely used in architecture due to their strength, durability, and flexibility. They can be used for various architectural elements such as roofs, walls, cladding, and structural components. Additionally, steel sheets offer a wide range of design possibilities and can be easily customized to meet specific architectural requirements.

Send your message to us

Galvanized Corrugated Steel Sheet in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords