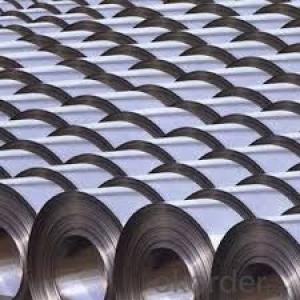

Hot Rolled Steel Coil /Cold Rolled Steel Coil/Color Steel Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot rolled coils/plates

Type: steel coil and steel plates

Material: SS400-Q235-Q345-SPHC

Width:1250mm 1500mm 1800mm 2000mm

HOT-ROLLED COIL/PLATES(Material: SS400-Q235A/B-SPHC) | |||

2.00*1250/1500L | 3.50*1250/1500L | 5.75*1250/1500L | 11.50*1250/1500L |

2.30*1250/1500L | 3.75*1250/1500L | 7.50*1250/1500L | 11.75*1250/1500L |

2.50*1250/1500L | 4.50*1250/1500L | 7.75*1250/1500L | 13.50*1250/1500L |

2.75*1250/1500L | 4.75*1250/1500L | 9.50*1250/1500L | |

3.00*1250/1500L | 5.50*1250/1500L | 9.75*1250/1500L | |

PATTERN-ROLLED COIL/PLATES(Material: Q235A-Q235B) | |||

3.00*1250L | 3.75*1250L | 4.75*1250L | 5.75*1250L |

3.50*1250L | 4.50*1250L | 5.50*1250L | 7.50*1250L |

MIDDEL-PLATE(Material: Q235A/B-Q345A/B) | |||

8*1800/2000L | 16*1800/2000L | 25*1800/2000L | 45*1800/2000L |

10*1800/2000L | 18*1800/2000L | 30*1800/2000L | 50*1800/2000L |

12*1800/2000L | 20*1800/2000L | 35*1800/2000L | |

14*1800/2000L | 221800/2000L | 401800/2000L | |

Name | galvanized steel coil dx52d z gi |

Grade | GB/T-12754: 2006, JIS3302, EN 10142, ASTM A653, JIS G3302, SGCC/SGCH, GB/T2518, European Standard, ASTM A792, JIS G3321, JIS G3317 |

BASE PLATE | Cold rolled steel sheet, hot dipped zinc coated steel sheet hot dipped A-Z coated steel sheet |

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

ZINC COATING | 40g-275g /m2 |

PAINT THICKNESS | Top:20+-5um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

BASE SHEET | Cold rolled steel sheet, hot dipped zinc coated steel sheet (small, regular or zero spangle), hot dipped A-Z coated steel sheet |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

Applications of cold rolled steel sheet coil :

1) Automotive bodies: filters, fuel tanks, etc.

2) Construction materials: roofings, welding pipes,

3) Electric and electronic appliances: computer cans, etc.

4) Steel cans: containers, etc.

5) Steel furniture: washing machines, refrigerators, microwaves, etc.

6) Drums

7) Office equipment: printer, recorders, etc.

8) Motors and transformers

Process of cold rolled steel sheet coil :

Pay off reel-double cut shear-welder-notcher-entry accumulator-pre cleaning section-furnace-hot bridle-zinc pot-air knife-after cooler-water quench-dryer- skin pass mill-dryer-tension leveler-dryer-chemical coater-chemical oven-cooler-exit accumulator-oiler-exit shear-tension reel.

Features of cold rolled steel sheet coil :

1) cold rolled steel coils prices is manufactured to have a long durability, strong corrosion resistance and shiny surface.

2) cold rolled steel coils prices features excellent forming properties, paintability, weldability, and is suitable for fabrication by forming, pressing and bending.

Q&A Acceptable payment term and way ?

ANSWER: T/T,L/C, T/T + L/C, D/P

Q&A Do you accept OA payment terms?

ANSWER: Yes, sure, but it normally depending on the order value

Q&A Do you have QC team?

ANSWER: Yeah, sure, our QC team is very important, they will keep the quality control for our products.

- Q: Are steel sheets suitable for high-traffic areas?

- Yes, steel sheets are highly suitable for high-traffic areas. Steel is a durable and strong material that can withstand heavy foot traffic without getting easily damaged. It is also resistant to wear and tear, making it an excellent choice for areas that experience a lot of activity. Additionally, steel sheets are easy to clean and maintain, further enhancing their suitability for high-traffic areas.

- Q: Are the steel sheets suitable for architectural cladding?

- Steel sheets are indeed appropriate for architectural cladding. Steel, being a sturdy and long-lasting substance, offers outstanding defense against weather conditions and external influences. It is easily malleable and can be crafted into diverse shapes, making it extremely adaptable for architectural purposes. Moreover, steel cladding provides a contemporary and polished appearance, permitting the creation of visually captivating building exteriors. Additionally, steel sheets can be coated or painted to augment their ability to resist corrosion and to further personalize their look. All in all, due to their strength, durability, versatility, and aesthetic allure, steel sheets are widely favored for architectural cladding.

- Q: What is the average cost of installing steel sheets?

- The average cost of installing steel sheets can vary depending on various factors such as the size of the project, the type and quality of the steel sheets, the location, and the labor costs. On average, the cost of installing steel sheets can range from $7 to $15 per square foot. However, it is important to note that this is just a rough estimate and actual costs may vary significantly. It is recommended to obtain quotes from multiple contractors or steel suppliers to get a more accurate estimate for a specific project.

- Q: Are the steel sheets suitable for automotive applications?

- Yes, steel sheets are highly suitable for automotive applications. Steel is widely used in the automotive industry due to its exceptional strength, durability, and versatility. It offers excellent crash resistance, making it ideal for vehicle structures to ensure passenger safety. Additionally, steel sheets can be easily formed into complex shapes, allowing for the production of various automotive components such as body panels, chassis, and frames. Steel also provides good corrosion resistance, which is crucial for withstanding harsh environmental conditions. Moreover, it is cost-effective and readily available, making it a popular choice for automakers. Overall, steel sheets are a reliable and suitable material for automotive applications.

- Q: How thick can steel sheets be?

- Steel sheets can be manufactured in various thicknesses, ranging from a few millimeters to several centimeters, depending on the specific application and manufacturing process.

- Q: What are the different edge treatments for steel sheets?

- Steel sheets can be treated with various edge techniques depending on the desired functionality and aesthetics. Some common treatments for steel sheets include: 1. Deburring: To enhance safety and prevent injuries during handling and installation, any burrs or sharp edges formed during manufacturing are removed. 2. Beveling: Creating a sloping edge on the steel sheet facilitates welding or joining multiple sheets. Beveled edges provide a smooth transition and strengthen the joint. 3. Chamfering: For a polished and finished look, a beveled edge is created on the steel sheet, primarily for aesthetic purposes. 4. Hemming: In the automotive and appliance industries, the edge of a steel sheet is bent back onto itself to create a safe and smooth edge, eliminating the need for additional finishing or edge protection. 5. Rolled edges: The edge of the steel sheet is bent in a curved or rounded shape to enhance structural integrity, reduce the risk of injury, and improve the overall appearance. 6. V-grooving: A V-shaped groove is cut along the edge of the steel sheet, commonly used for decorative purposes or to create a clean and precise joint when joining multiple sheets. 7. Flanging: The edge of the steel sheet is bent or folded at a specific angle to increase rigidity and strength, particularly in applications where the sheet needs to support weight or resist bending. Each edge treatment serves a specific purpose and should be chosen based on project requirements, considering factors such as functionality, safety, aesthetics, and ease of fabrication.

- Q: How do steel sheets perform in extreme temperatures?

- Steel sheets have excellent performance in extreme temperatures. Steel is known for its high strength and durability, which allows it to withstand both extremely hot and extremely cold conditions. In high temperatures, steel sheets maintain their structural integrity and do not deform or melt. Similarly, in cold temperatures, steel does not become brittle or lose its strength. This makes steel sheets a reliable choice for various applications in extreme temperature environments.

- Q: What are the potential drawbacks of using steel sheets?

- There are several potential drawbacks of using steel sheets in various applications. Firstly, steel sheets are prone to corrosion. If not properly protected or coated, steel sheets can rust when exposed to moisture or certain environmental conditions. This can significantly affect their structural integrity and lifespan. Secondly, steel sheets can be heavy and difficult to handle. This can pose challenges during transportation, installation, and maintenance. The weight of steel sheets may also limit their use in certain applications where weight restrictions are in place. Additionally, steel sheets can be expensive compared to other materials. The cost of steel production, processing, and customization can be higher than alternative materials, making steel sheets less financially viable in some projects. Another potential drawback of steel sheets is their limited design flexibility. Steel sheets are often manufactured in standard sizes and shapes, which may not always meet specific design requirements. Modifying steel sheets can be time-consuming and costly, limiting their adaptability for unique or complex projects. Moreover, steel sheets have a relatively high thermal conductivity. This means that they can transfer heat quickly, making them less effective in providing insulation. In applications where thermal insulation is crucial, alternative materials may be more suitable. Lastly, steel sheets are not environmentally friendly. The production of steel involves significant energy consumption and carbon emissions. Additionally, the extraction and mining of raw materials used in steel production can have detrimental effects on the environment. Overall, while steel sheets have numerous advantages such as strength and durability, it is important to consider these potential drawbacks when choosing the appropriate material for a specific application.

- Q: How do you calculate the weight of a steel sheet?

- To calculate the weight of a steel sheet, you need to know its dimensions (length, width, and thickness) and the density of the specific type of steel being used. The weight can be calculated by multiplying the volume (length x width x thickness) by the density.

- Q: What is the process of manufacturing steel sheets?

- The process of manufacturing steel sheets involves several steps. First, iron ore is extracted from the ground and processed to remove impurities. This iron ore is then smelted in a blast furnace, along with coke and limestone, to produce molten iron. The molten iron is further refined in a basic oxygen furnace or an electric arc furnace to remove any remaining impurities and adjust the desired composition. Once the iron has been refined, it is converted into steel by adding alloying elements such as carbon, manganese, and other elements as required. The molten steel is then cast into large slabs or ingots. These slabs are reheated and passed through rolling mills to reduce their thickness and shape them into long, flat sheets. The sheets are then cooled, coated or treated as necessary, and cut into desired sizes before being packaged and shipped for various applications.

Send your message to us

Hot Rolled Steel Coil /Cold Rolled Steel Coil/Color Steel Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords