Galvalume Steel Coils in Best Quality and Competative Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

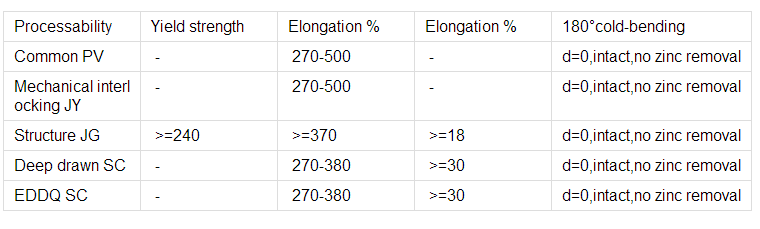

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the pros with stainless steel? You don't have to oil them as much or you don't have to oil them at all?Is the rifling in the barrel typically stainless steel as well? if so, is this better accuracy or does the rifling last longer then conventional?are they worth the extra money?Thanks for any info you can provide!

- Stainless Steel Handguns

- Q: What are the dimensions of a typical steel coil?

- The dimensions of a typical steel coil can vary depending on its intended use and manufacturing specifications. However, common dimensions for a steel coil typically range from 0.15 to 3.5 millimeters in thickness, and 600 to 2,000 millimeters in width. The inner diameter of the coil can be around 508 to 610 millimeters, and the maximum outer diameter can be up to 2,000 millimeters.

- Q: What is the average amount carbon emissions of steel per pound produced?

- Carbon okorder /... - Similar pages - Life-cycle energy and emissions of marine energy devices | Carbon ...Carbon dioxide emissions per unit mass of steel: 1.75 tCO2/tonne steel ; Total mass of steel in device: 665 tonnes ; Carbon dioxide emissions due to .

- Q: How are steel coils coated for corrosion resistance?

- Steel coils are typically coated for corrosion resistance using various methods such as hot-dip galvanizing, electroplating, or applying a protective layer of paint or powder coating.

- Q: Already on my team is Empoleon lvl 82Heatran lvl 74Scizor lvl 34Magnezone lvl 38What other steel types should I choose?

- Some other good Steel types to consider are: Steelix, Metagross, Lucario, and Excadrill. If you aren't against using legendaries, Genesect, Diagla, and Jirachi are good choices too. I would recommend Skarmory, but Skarmory is better to use in a competitve battle setting, and not a regular in-game setting (which is what I assume you're doing). The other Steel types you've chosen are very good.

- Q: How are steel coils processed for specific applications?

- Steel coils are processed for specific applications through a series of carefully planned steps. The process begins with the selection of the appropriate grade and thickness of steel, which is determined based on the requirements of the end application. Once the steel coils are received, they undergo a series of processing steps to transform them into the desired product. The first step in processing steel coils is known as uncoiling, where the coil is unwound and straightened. This ensures that the coil is flat and ready for further processing. The uncoiled steel is then cleaned to remove any dirt, oil, or rust that may be present on the surface. This is typically done through a process called pickling, which involves immersing the steel in a bath of acid to remove any impurities. After cleaning, the steel undergoes various shaping processes depending on the desired application. This can include processes such as slitting, where the coil is cut into narrower strips, or shearing, where it is cut into specific lengths. These shaping processes are often performed using specialized machinery that can handle the high strength and thickness of steel. Once the steel has been shaped, it may undergo additional processes to enhance its properties. For example, it may be heat treated to increase its strength or hardness, or it may undergo a coating process to improve its corrosion resistance. Coating processes can include techniques such as galvanizing, where the steel is coated with a layer of zinc, or painting, where it is coated with a layer of paint. Finally, the processed steel coils are inspected for quality and undergo any necessary finishing processes. This can include processes such as trimming the edges to remove any irregularities, or applying protective coatings to prevent damage during transportation or storage. Overall, the processing of steel coils for specific applications is a complex and carefully controlled process. It involves a combination of shaping, cleaning, coating, and finishing processes to ensure that the steel meets the required specifications and is ready for use in various industries such as automotive, construction, and manufacturing.

- Q: How are steel coils used in the production of containers?

- Steel coils are used in the production of containers as they are the primary material for manufacturing container bodies. These coils are shaped and welded into the desired container shape, providing strength and durability to the final product.

- Q: What is the role of steel coils in the production of appliances?

- The role of steel coils in the production of appliances is to provide a strong and durable material for various components, such as the outer body, internal structures, and key parts. Steel coils are used to manufacture appliance parts like panels, frames, and brackets, ensuring stability, strength, and longevity. The versatility and strength of steel make it an ideal choice for appliances, as it can withstand heavy loads and provide the necessary support and protection.

- Q: What are the challenges in storing and handling steel coils?

- Storing and handling steel coils present several challenges, including their sheer weight and size, which can make transportation and storage difficult. The coils need to be stored in a way that prevents damage and deformation, as steel coils are susceptible to rust, corrosion, and scratching. Additionally, ensuring proper ventilation and moisture control is crucial to prevent the growth of mold or moisture-related damage. Safety precautions must also be taken during handling and transportation to avoid accidents or injuries.

- Q: Can steel coils be stacked on top of each other?

- Yes, steel coils can be stacked on top of each other.

Send your message to us

Galvalume Steel Coils in Best Quality and Competative Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords